Method for determining specimen dry friction surface temperature field

A dry friction and temperature field technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to obtain continuous steady-state output, cumbersome measurement work, and significant random error effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A method for determining the temperature field of a dry friction surface of a sample. The concrete steps of this embodiment are:

[0067] Step 1: Measure the temperature of the dry friction surface of the sample

[0068] The material of the sample is ZA27; the cross section of the sample is circular, the diameter of the circle is 8mm, and the length of the sample is 30mm.

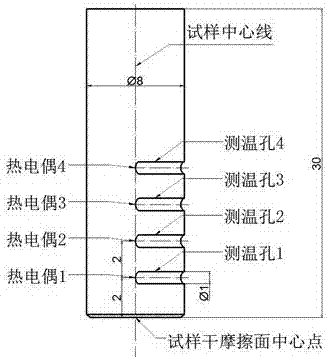

[0069] There is a temperature measuring hole near the dry friction surface of the sample, such as figure 1 As shown, there are 4 temperature measuring holes, and the center line of the temperature measuring holes intersects the center line of the sample. The temperature measuring holes are parallel to the friction surface and distributed evenly. The diameter of the temperature measuring holes is 1 mm, and the hole distance is 2 mm.

[0070] The temperature measuring holes are equipped with thermocouples, and each thermocouple is respectively connected with a thermometer.

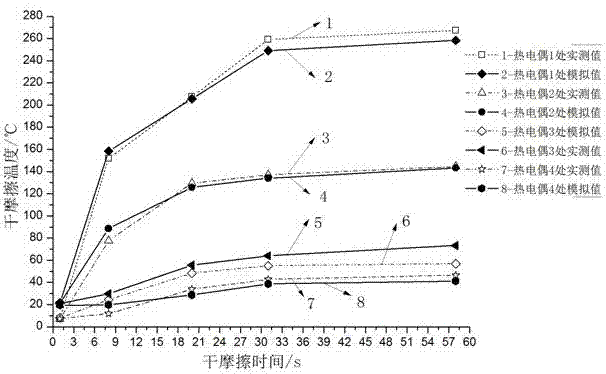

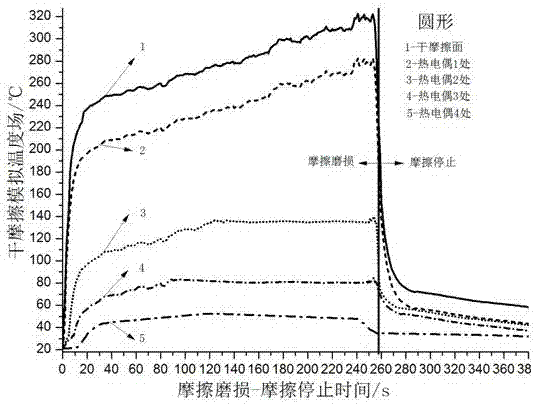

[0071] The temperature o...

Embodiment 2

[0123] A method for determining the temperature field of a dry friction surface of a sample. The concrete steps of this embodiment are:

[0124] Step 1: Measure the temperature of the dry friction surface of the sample

[0125] The material of the sample is Zn-40Al; the cross section of the sample is square, the side length of the square is 6 mm, and the length of the sample is 22 mm.

[0126] There is a temperature measuring hole near the dry friction surface of the sample, such as Figure 4 As shown, there are 2 temperature measuring holes, the center line of the temperature measuring hole intersects the center line of the sample, the temperature measuring holes are parallel to the friction surface and distributed evenly, the diameter of the temperature measuring holes is 1mm, and the hole distance is 3mm.

[0127] The temperature measuring holes are equipped with thermocouples, and each thermocouple is respectively connected with a thermometer. When the sample is subject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com