Performance testing device and method for screw pump

A technology of testing device and testing method, which is applied in the direction of neural learning method, pump control, biological neural network model, etc., can solve the problem that the performance of screw pump cannot be fully understood, and computer simulation technology cannot replace screw pump and screw pump performance testing Solving problems such as single measurement factors of the device, achieving the effect of reducing the workload, prolonging the service life and improving the test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions of the present invention will be further described below with reference to the accompanying drawings, but the content protected by the present invention is not limited to the following.

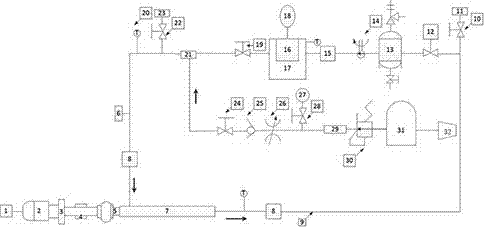

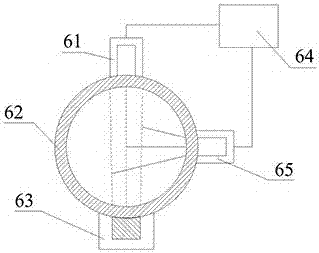

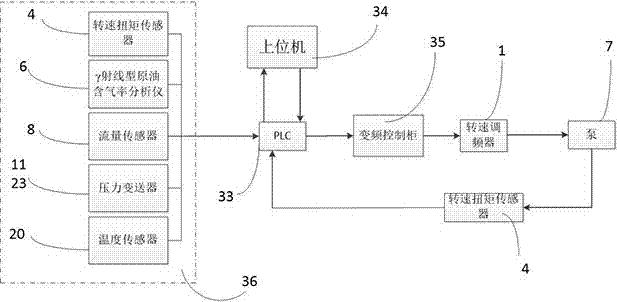

[0050] figure 1 It is a schematic diagram of the performance simulation experiment device of the screw pump under different operating conditions of the present invention, the frequency modulator 1, the three-phase asynchronous motor 2, the coupling 3, the rotational speed torque sensor 4, the screw pump rotor 5, and the analysis of the gas content of the γ-ray type crude oil. Instrument 6, screw pump 7, flow sensor 8, pipeline 9, first stop valve 10, first pressure transmitter 11, electric regulating valve 12, three-phase separator 13, booster pump 14, mass flow meter 15, storage Liquid tank 16, electric heater 17, liquid level gauge 18, second shut-off valve 19, temperature sensor 20, oil-gas mixer 21, third shut-off valve 22, second pressure transmitter 23, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com