Chitosan-containing humic acid liquid fertilizer with effect of promoting rooting and fruiting

A technology of chitosan and humic acid, applied in the field of liquid fertilizer, can solve the problems of undisclosed root growth, etc., and achieve the effects of improving soluble sugar content, growing healthily, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

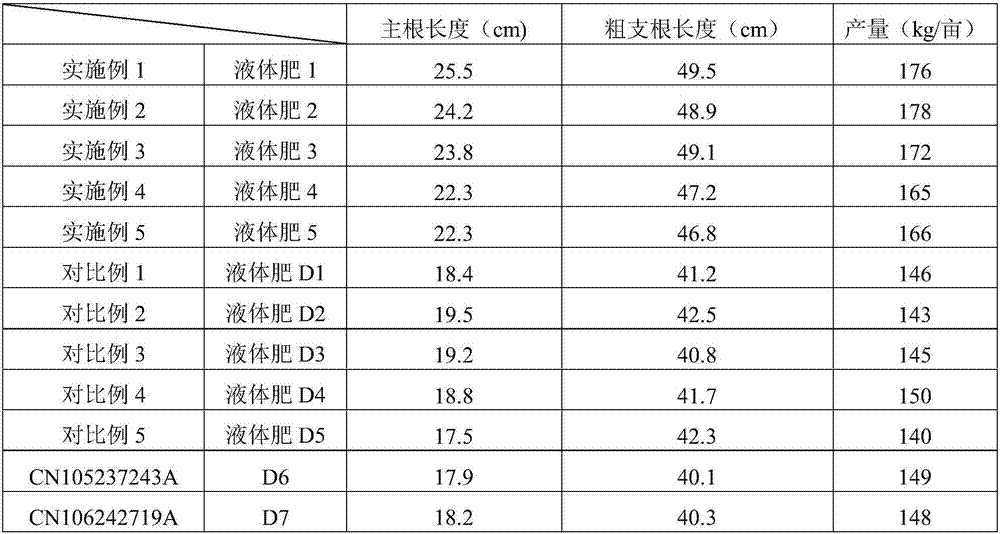

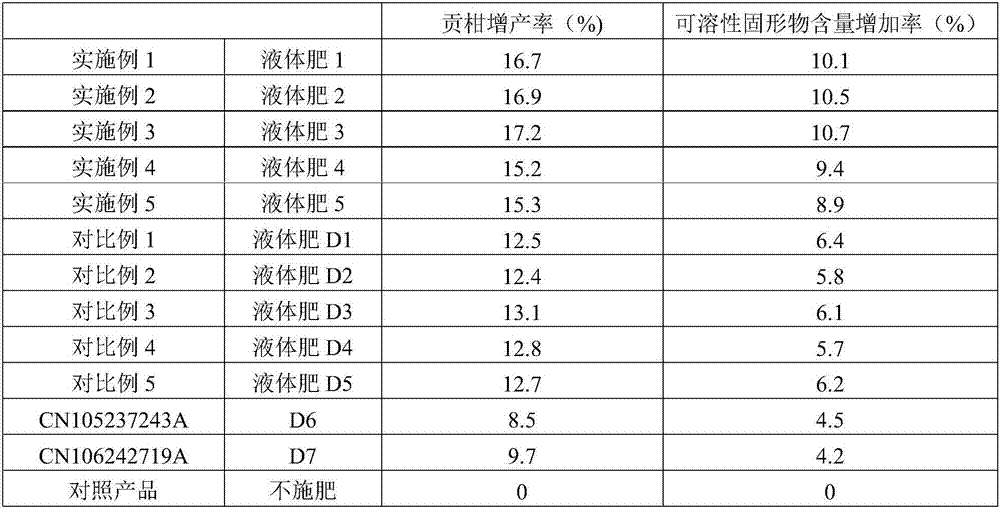

Examples

Embodiment 1

[0039]Prepare raw materials: 9kg of urea, 7kg of monoammonium phosphate, 23kg of potassium sulfate, 3.8kg of magnesium nitrate, 1.2kg of zinc sulfate heptahydrate, 1.9kg of ferrous sulfate heptahydrate, 67.5kg of sugar factory waste liquid degradation solution (which contains 27kg of organic matter), Humic acid 4.2kg, chitosan 1.2kg, sodium carboxymethylcellulose 0.35kg, xanthan gum 0.35kg, benzalkonium chloride 0.5kg, water 20.5kg. Put the above raw materials into the reaction kettle according to the weight ratio, and finally add the corresponding amount of water, control the temperature at 40-50 degrees, the stirring speed is 140 rpm, and continue to stir for 25 minutes. After fully mixing, measure and pack to obtain chitosan. The finished product of sugar humic acid liquid fertilizer 1.

Embodiment 2

[0041] Prepare raw materials: 15kg of ammonium nitrate, 6kg of monoammonium phosphate, 19kg of potassium chloride, 3.5kg of magnesium nitrate, 1.4kg of zinc sulfate heptahydrate, 2.1kg of ferrous ammonium sulfate, 60kg of sugar factory waste liquid degradation solution (including 30kg of organic matter), Humic acid 4kg, chitosan 1kg, sodium carboxymethylcellulose 0.5kg, xanthan gum 0.5kg, carbendazim 0.8kg, water 16.2kg. Put the above raw materials into the reaction kettle according to the weight ratio, and finally add the corresponding amount of water, control the temperature at 40-50 degrees, the stirring speed is 160 rpm, and continue to stir for 30 minutes. After fully mixing, measure and pack to obtain chitosan The finished product of sugar humic acid liquid fertilizer 2.

Embodiment 3

[0043] Prepare raw materials: 25kg of ammonium chloride, 20kg of potassium dihydrogen phosphate, 3.3kg of magnesium chloride, 1.1kg of zinc chloride, 1.9kg of ferrous sulfate heptahydrate, 42kg of sugar factory waste liquid degradation solution (including 25kg of organic matter), 5.6 of humic acid kg, chitosan 1.6kg, sodium naphthalene acetate 0.4kg, acrylate 0.4kg, chlorothalonil 0.8kg, water 15kg. Put the above raw materials into the reaction kettle according to the weight ratio, and finally add the corresponding amount of water, control the temperature at 40-50 degrees, the stirring speed is 120 rpm, stir continuously for 20 minutes, mix well, measure and pack to get chitosan The finished product of sugar humic acid liquid fertilizer 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com