Method for batch preparation of graphene quantum dots

A graphene quantum dot, batch technology, applied in graphene, single-layer graphene, chemical instruments and methods, etc., can solve the problems of graphene quantum dot activity damage, uncontrollable quantum dot shape and size, and expensive preparation cost. , to achieve the effect of less demand for raw materials and equipment types, good industrial application prospects, and simple technical processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present embodiment prepares graphene quantum dots as follows:

[0031] (1), liquid nitrogen impregnation ultra-low temperature pretreatment

[0032] Weigh 100mg of high-purity graphite powder into a centrifuge tube with a volume of 50mL, and inject 40mL of liquid nitrogen into the centrifuge tube. The graphite powder is completely immersed in liquid nitrogen; place the centrifuge tube open in a liquid Soak in the nitrogen insulation barrel for 10 minutes;

[0033] (2), ultrasonic chemical peeling

[0034] Take out the centrifuge tube, and immediately disperse the graphite powder in 100 mL of a mixed solvent composed of water and isopropanol at a volume ratio of 1:1 after the liquid nitrogen is completely vaporized, and ultrasonically treat it at 135W for 10 minutes; then the product is heated at 2000 Centrifuge for 30 minutes at rpm, and take the supernatant to obtain graphene quantum dots.

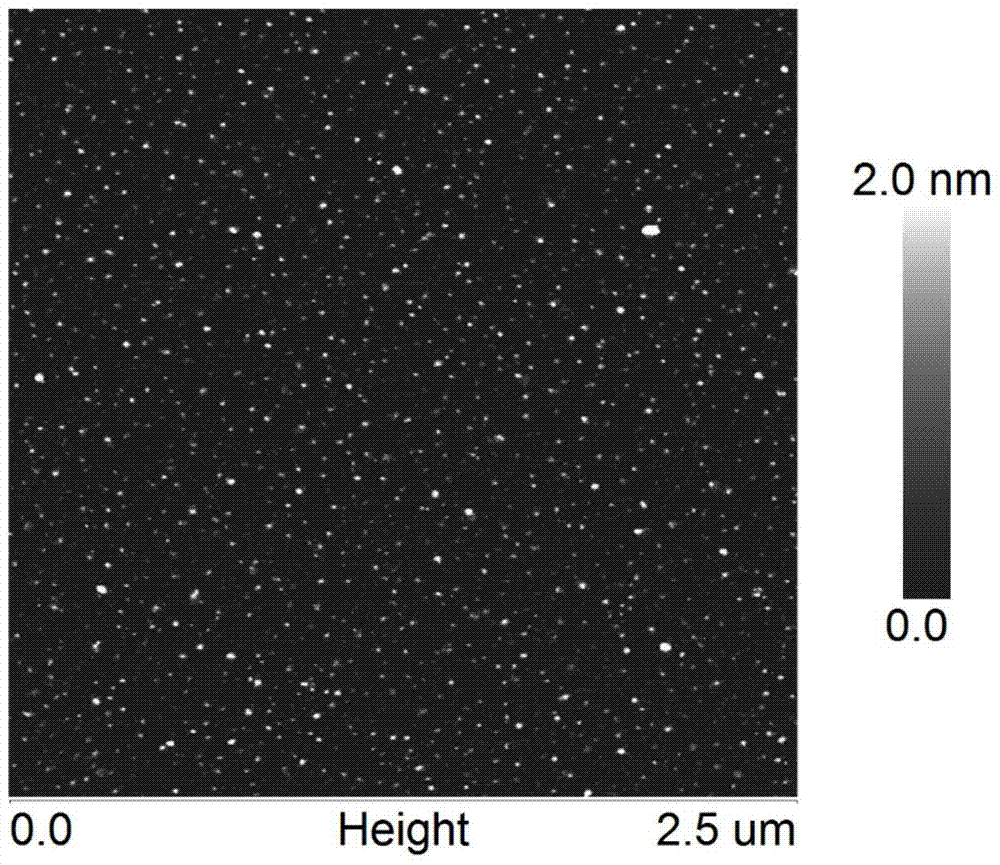

[0035] Such as figure 1 As shown, the graphene quantum dots prepared i...

Embodiment 2

[0037] The present embodiment prepares graphene quantum dots as follows:

[0038] (1), liquid nitrogen impregnation ultra-low temperature pretreatment

[0039] Weigh 100mg of high-purity graphite powder into a centrifuge tube with a volume of 50mL, and inject 40mL of liquid nitrogen into the centrifuge tube. The graphite powder is completely immersed in liquid nitrogen; place the centrifuge tube open in a liquid Soak in the nitrogen insulation barrel for 10 minutes;

[0040] (2), ultrasonic chemical peeling

[0041] Take out the centrifuge tube, and immediately disperse the graphite powder in 100mL of a mixed solvent composed of water and isopropanol in a volume ratio of 3:2 after the liquid nitrogen is completely vaporized, and ultrasonically treat it for 60 minutes at 135W; Centrifuge for 30 minutes at rpm, and take the supernatant to obtain graphene quantum dots.

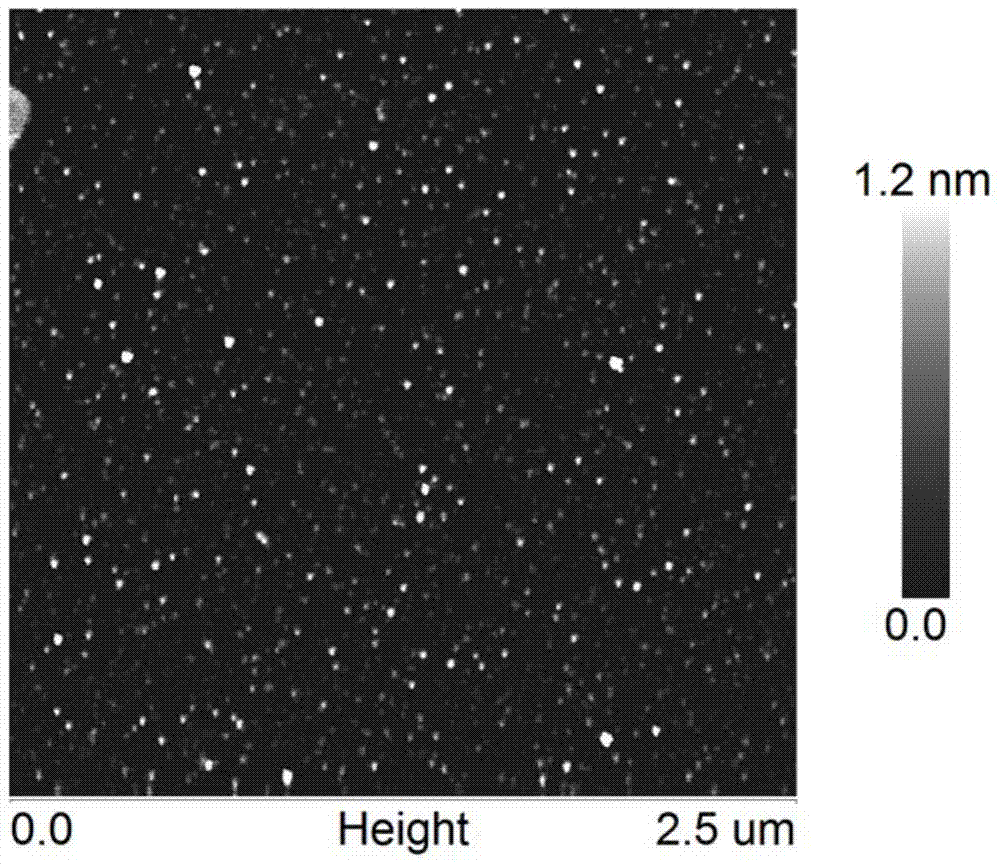

[0042] Such as figure 2 As shown, the graphene quantum dots prepared in this embodiment are evenly distri...

Embodiment 3

[0044] The present embodiment prepares graphene quantum dots as follows:

[0045] (1), liquid nitrogen impregnation ultra-low temperature pretreatment

[0046] Weigh 300mg of high-purity graphite powder into a centrifuge tube with a volume of 50mL, and inject 40mL of liquid nitrogen into the centrifuge tube. The graphite powder is completely immersed in liquid nitrogen; place the centrifuge tube open in a liquid Soak in a nitrogen insulation barrel for 60 minutes;

[0047] (2), ultrasonic chemical peeling

[0048] Take out the centrifuge tube, and immediately disperse the graphite powder in 300mL of a mixed solvent composed of water and isopropanol at a volume ratio of 2:1 after the liquid nitrogen is completely vaporized, and ultrasonically treat it for 60 minutes at an intensity of 135W; Centrifuge for 30 minutes at rpm, and take the supernatant to obtain graphene quantum dots.

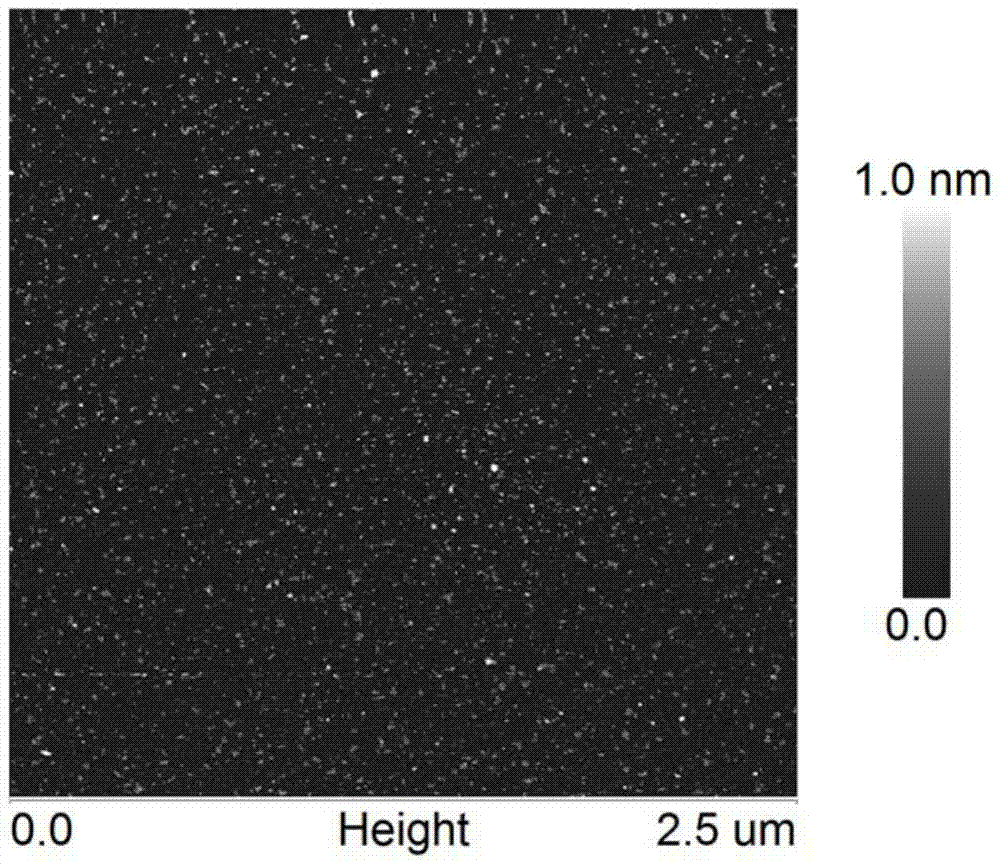

[0049] Such as image 3 As shown, the graphene quantum dots prepared in this embodiment are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com