Laser scanning automatic unstacking device and method

A technology of laser scanning and laser scanner, which is applied in the direction of unstacking, transportation and packaging of objects, stacking of objects, etc., can solve the problems of inconvenient movement, single function, simple structure, etc., and achieve convenient real-time monitoring and intelligent improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

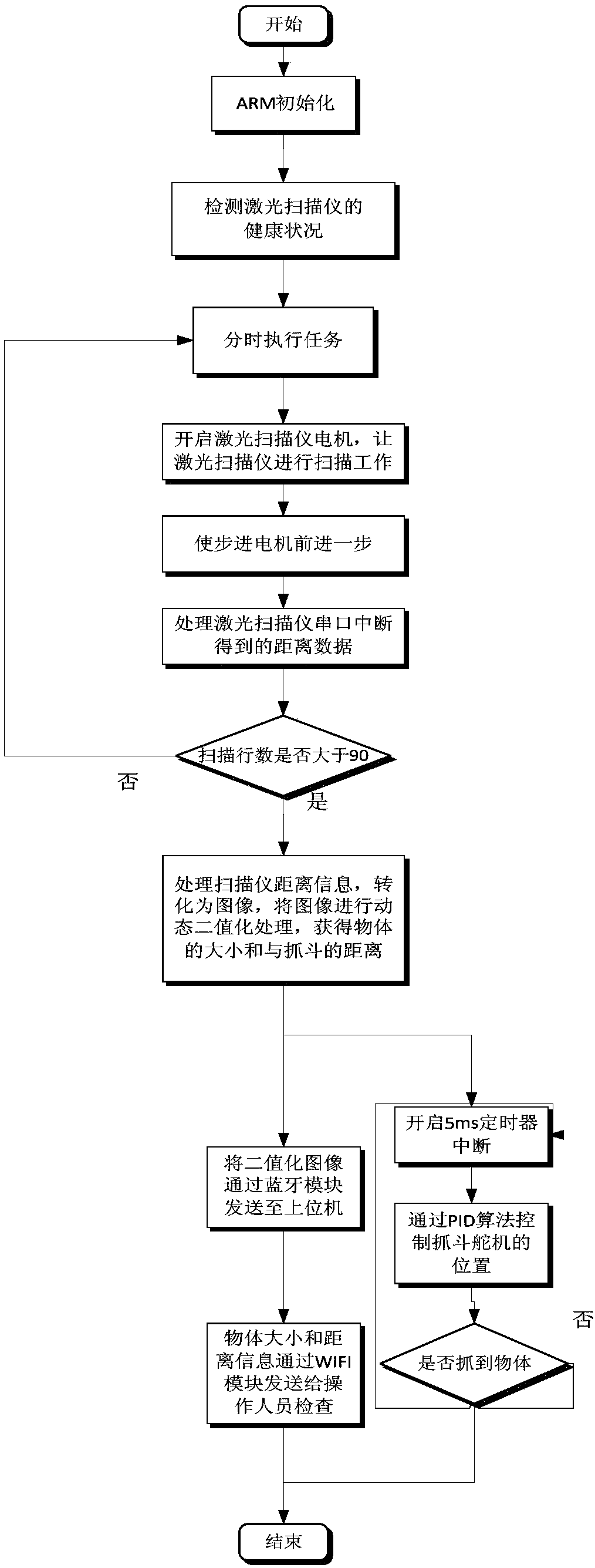

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

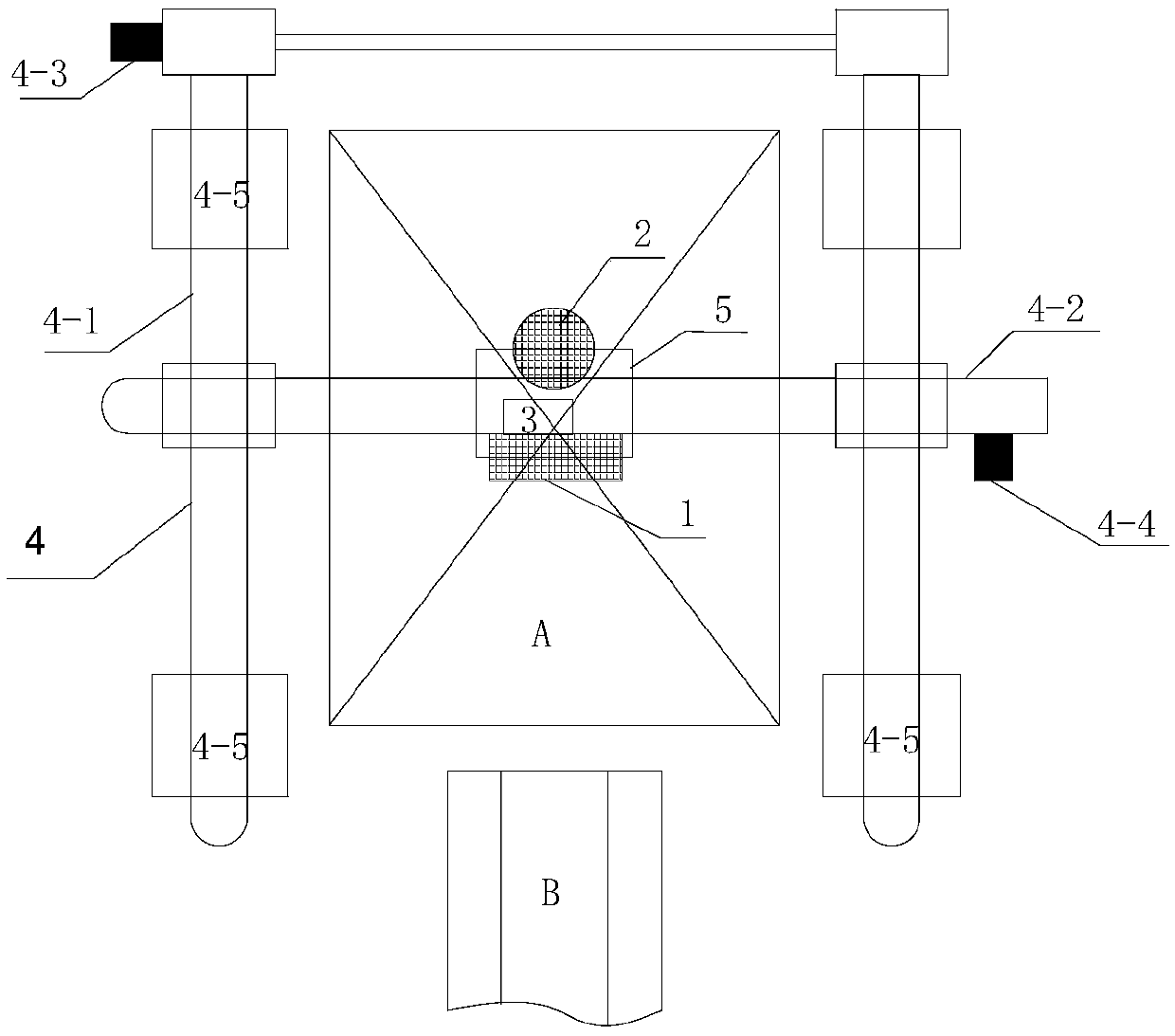

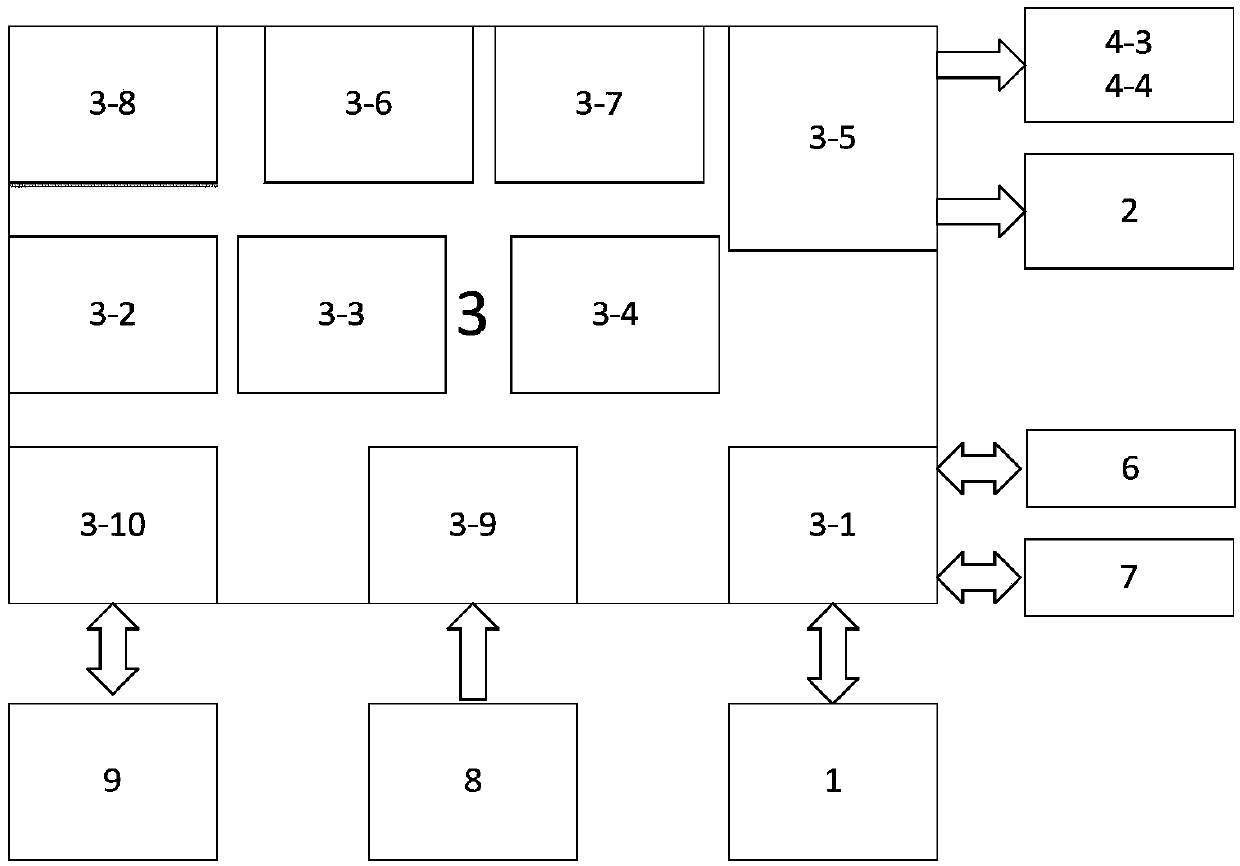

[0051] like figure 1 As shown, a laser scanning automatic destacking device of the present invention includes a three-dimensional sliding guide rail 4 installed around the cargo stacking place A. There is a laser scanner 1 , a grab 2 and an embedded processor 3 .

[0052] Laser scanner 1: used to collect the distance information from the cargo and transmit it to the embedded processor 3. The laser scanner 1 includes a rotating motor installed on the laser head. The rotating motor adjusts the laser head to a corresponding angle according to the control instructions of the embedded processor 3 and sends the angle information of the laser head to the embedded processor 3 . The laser scanner 1 uses a low-cost 360-degree two-dimensional laser scanning ranging system (RPLIDAR). This sensor uses serial port communication to communicate wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com