SMA fiber material automatic delivery device and method

A fiber material and delivery device technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as inaccurate measurement, high equipment failure rate, production line waiting for materials, etc., to solve inaccurate measurement, improve the working environment, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

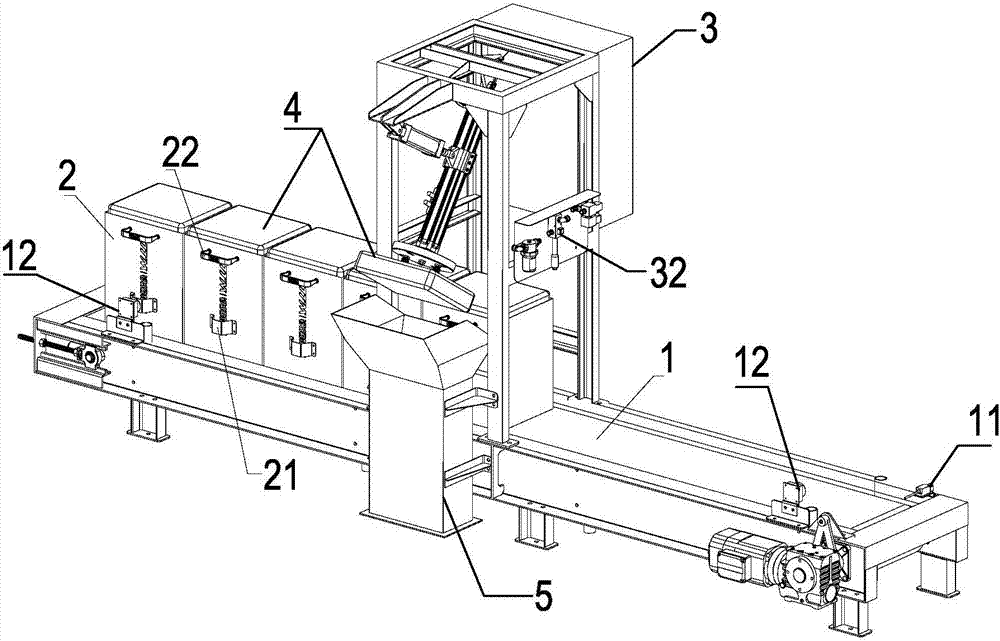

[0028] refer to Figure 1-3 , an automatic delivery device for SMA fiber materials, including: a transmission mechanism, a material storage mechanism 2, a delivery mechanism 3, a high temperature degradable fiber storage bag 4, a control mechanism and a material receiving mechanism 5; in this embodiment, the The transmission mechanism is a belt conveyor provided with a servo reduction motor.

[0029] The storage mechanism 2 is vertically arranged on the surface of the conveyor belt 1 of the transmission mechanism; the storage mechanism 2 has a storage cavity, and the fiber storage bags 4 are stacked in the storage cavity;

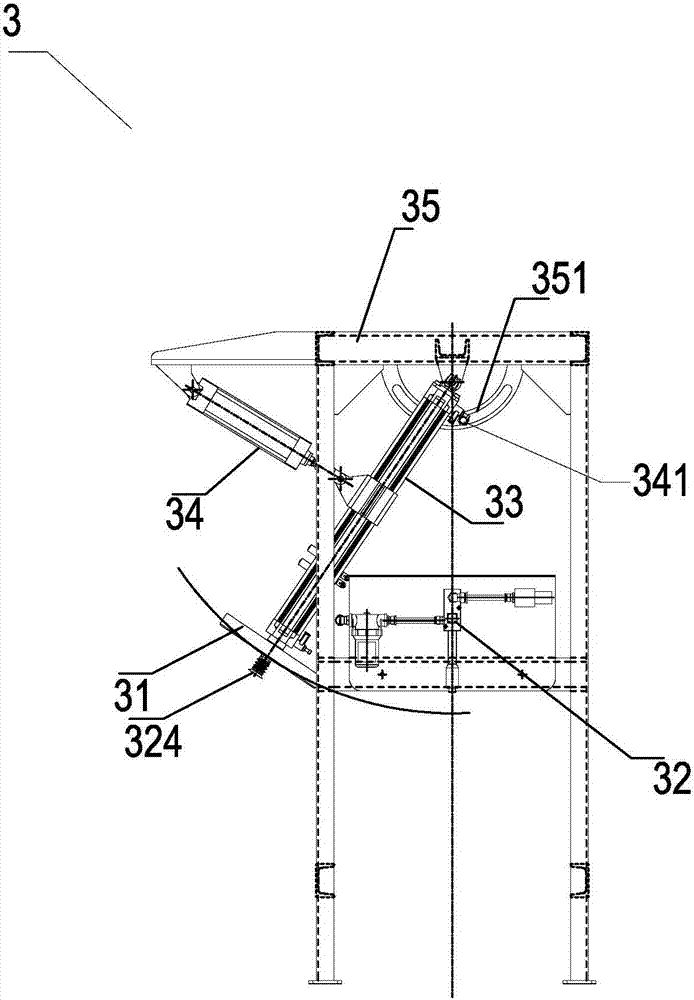

[0030] The delivery mechanism 3 includes a grabbing device 31, an air control module 32, a swing cylinder 33 and a grabbing cylinder 34 and a frame 35; the frame 35 is vertically arranged on the conveyor belt 1 surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com