High-quality automatic assembly equipment for pump core of infusion pump and assembly method of automatic assembly equipment

An automatic assembly and infusion pump technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve problems such as inability to assemble stably, achieve assembly accuracy and quality assurance, and reduce human contact with infusion pump pump cores, assembly Automatic and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below.

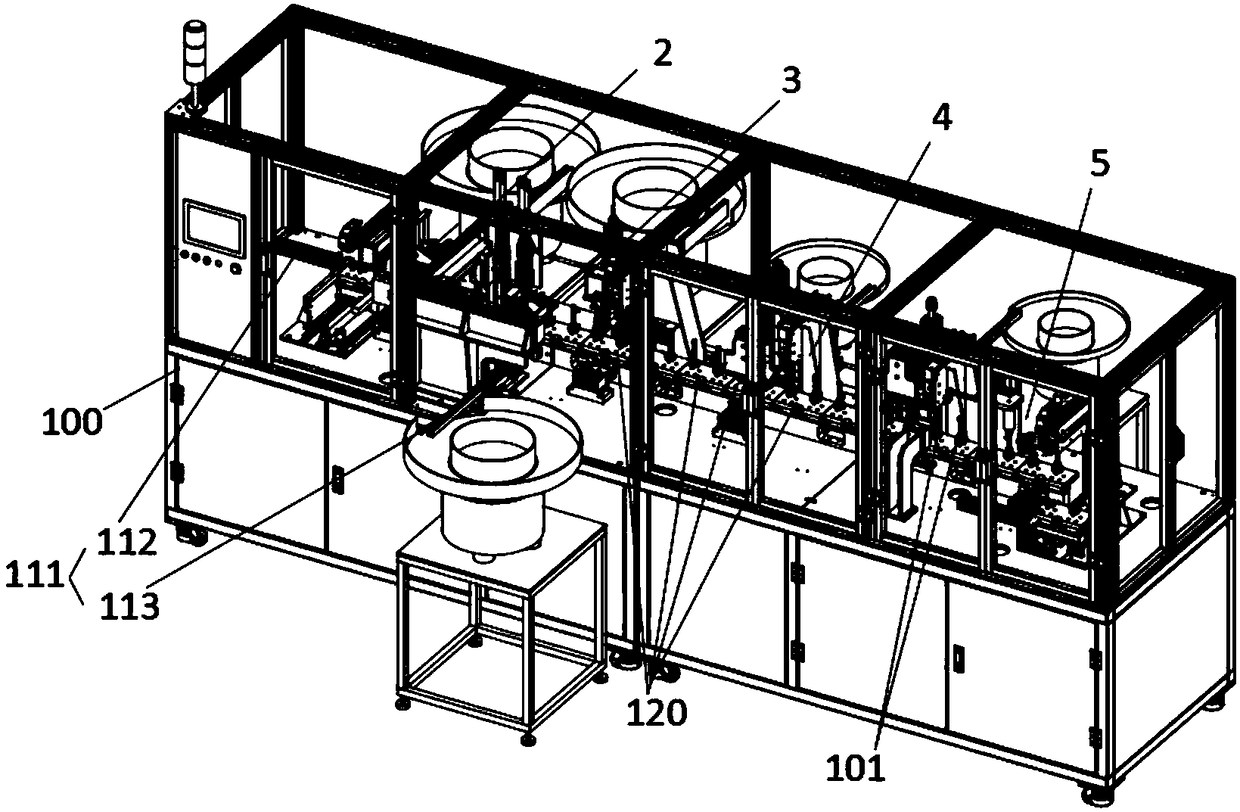

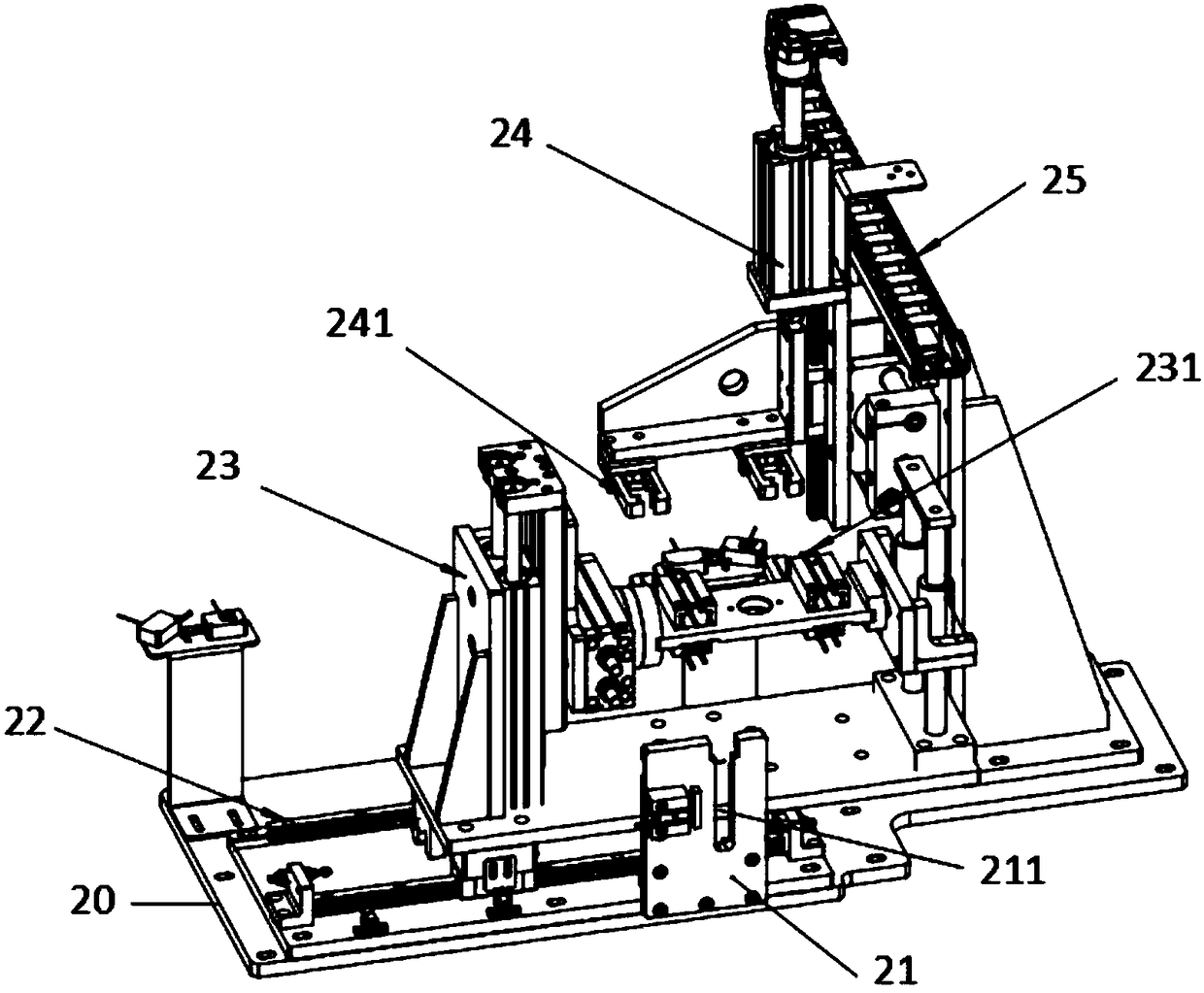

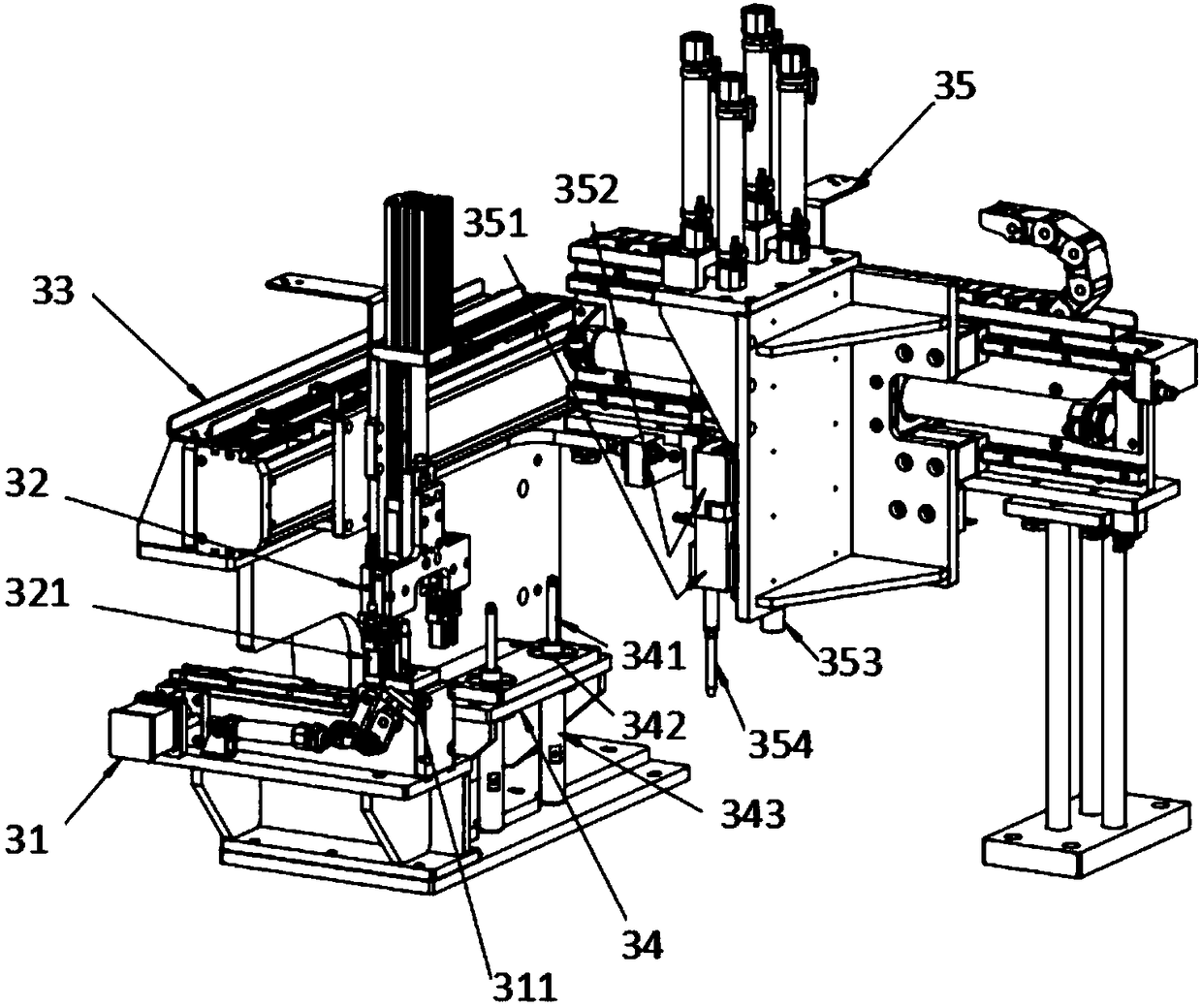

[0029] Such as Figure 1~9 , a high-quality automatic assembly equipment for infusion pump cores, used to automatically assemble a base 101, a push rod, a silicone tube, and two silicone rings into an infusion pump core, including a body 100, which includes a slide The rail mounting seat extends from the beginning of the fuselage 100 to the tail end with a horizontal slide rail 111. The horizontal slide rail 111 includes a horizontal slide rail 112 and a longitudinal slide rail 113. The slide rail mounting seat is provided with and flexibly connected to the horizontal slide rail 112. Both sides of the slide rail mounting seat are movably connected to the longitudinal slide rail 113;

[0030] On the horizontal slide rail 111 is arranged a transfer jig plate 120 that moves along the horizontal slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com