PCB clamping and conveying mechanism and working method thereof

A PCB circuit board, clamping transmission technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of processing, PCB circuit board pollution, disadvantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

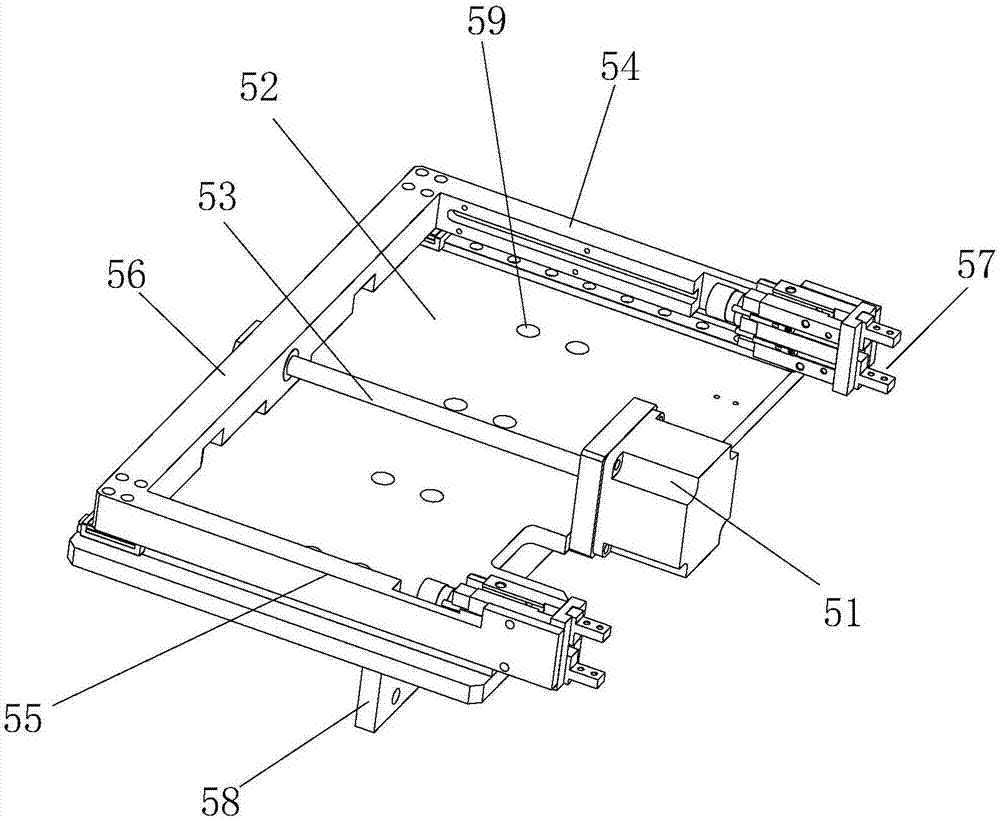

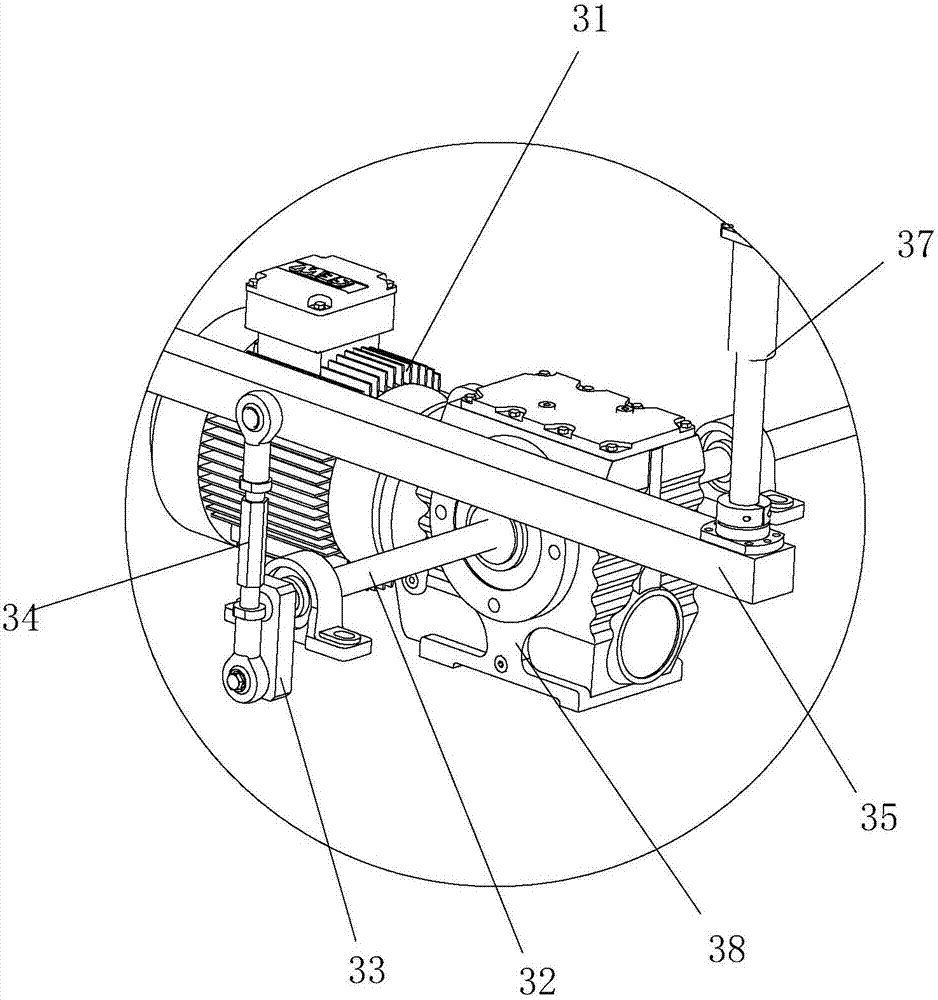

[0024] Example 1 as figure 1 As shown, the PCB circuit board clamping transmission mechanism of this embodiment includes: a left clamping arm support beam 21 and a right clamping arm support beam 22 arranged in parallel, for clamping the first left clamping arm 5 and the first clamping arm 5 of the PCB circuit board. One right clamp arm 6, the second left clamp arm 7, the second right clamp arm 8, the upper end faces of the left clamp arm support beam 21 and the right clamp arm support beam 22 are provided with guide chute respectively, the first left clamp arm 5, the second clamp arm One right jig arm 6, the second left jig arm 7, the second right jig arm 8 are identical in structure and arranged in pairs, as figure 2 As shown, each clamping arm includes a base plate 52, a clamping assembly, a screw mandrel 53, and a third motor 51. The lower end surface of each base plate 52 protrudes from a guide block 58 that is slidably matched with a guide chute, so that the first left ...

Embodiment 2

[0027] Embodiment 2 The above-mentioned PCB circuit board clamping transmission mechanism is mainly used in the transportation between the three stations of loading, printing and discharging during PCB circuit board production. In the initial state, the first left clamping arm and the first right clamping arm The arm is placed at the loading station, and the second left jig arm and the second right jig arm are placed under the printing station.

[0028] A working method of a PCB circuit board clamping transmission mechanism, comprising the following steps: setting a first left clamping arm 5 and a first right clamping arm 6 that can be synchronously stretched, lifted and translated at a loading station of a PCB circuit board production line; Set the second left clamping arm 7 and the second right clamping arm 8 that can be synchronously telescopic, lifted and translated at the printing station of the PCB circuit board production line; The printed PCB circuit board 11 of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com