Cutting equipment

A technology of cutting equipment and ports, which is applied in the field of cutting equipment, can solve problems such as low tightness, loose plug connectors, and poor protection capabilities of plug connectors, and achieve the effect of increasing safety and stability and preventing loose plug connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

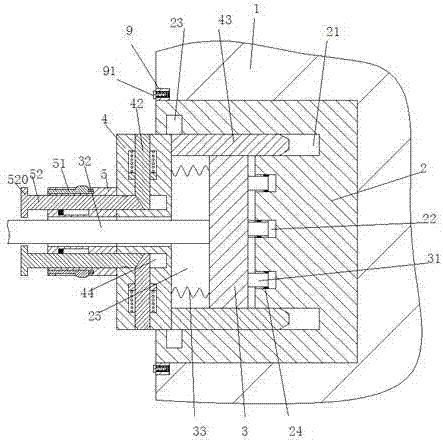

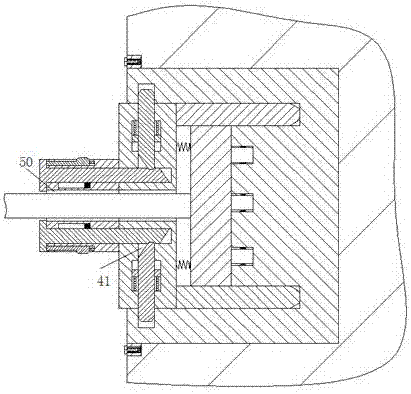

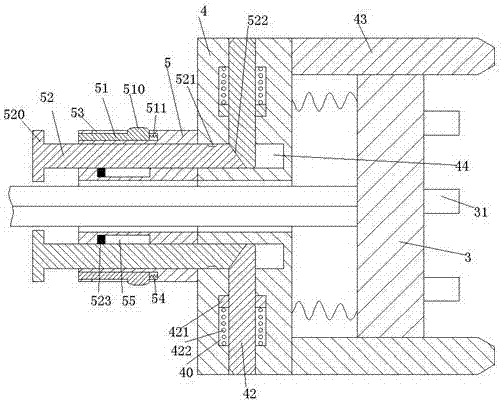

[0019] Combine below Figure 1-5 The present invention will be described in detail.

[0020] refer to Figure 1-5 , a cutting device according to an embodiment of the present invention, including a body 1, a power supply port 2, an electrical connector 3 matched with the power supply port 2, and a supporting device for protecting the electrical connector 3 , the upper and lower sides of the power supply port 2 are provided with threaded blocks 9 at the same time, the threaded blocks 9 are provided with threaded holes, and the threaded holes are fitted with bolts 91, and the power supply port 2 passes through the bolts 91 While being fastened in the body 1, the power supply port 2 is provided with a cavity 25 with the port facing left, and a spring hole 22 is arranged in the right end wall of the cavity 25, and in the spring hole 22 A power supply sheet 24 is provided, the right end of the electrical connector 3 is fixedly provided with an insert spring 31 matching the insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com