Composite Solar Collector

A solar collector and solar cell technology, applied in solar collectors, components of solar collectors, solar collectors in specific environments, etc., can solve the problems of fragility of unglazed solar collectors, and achieve The effect of increasing lifespan, increasing efficiency and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] The composite solar collector will be described in detail below according to the accompanying drawings.

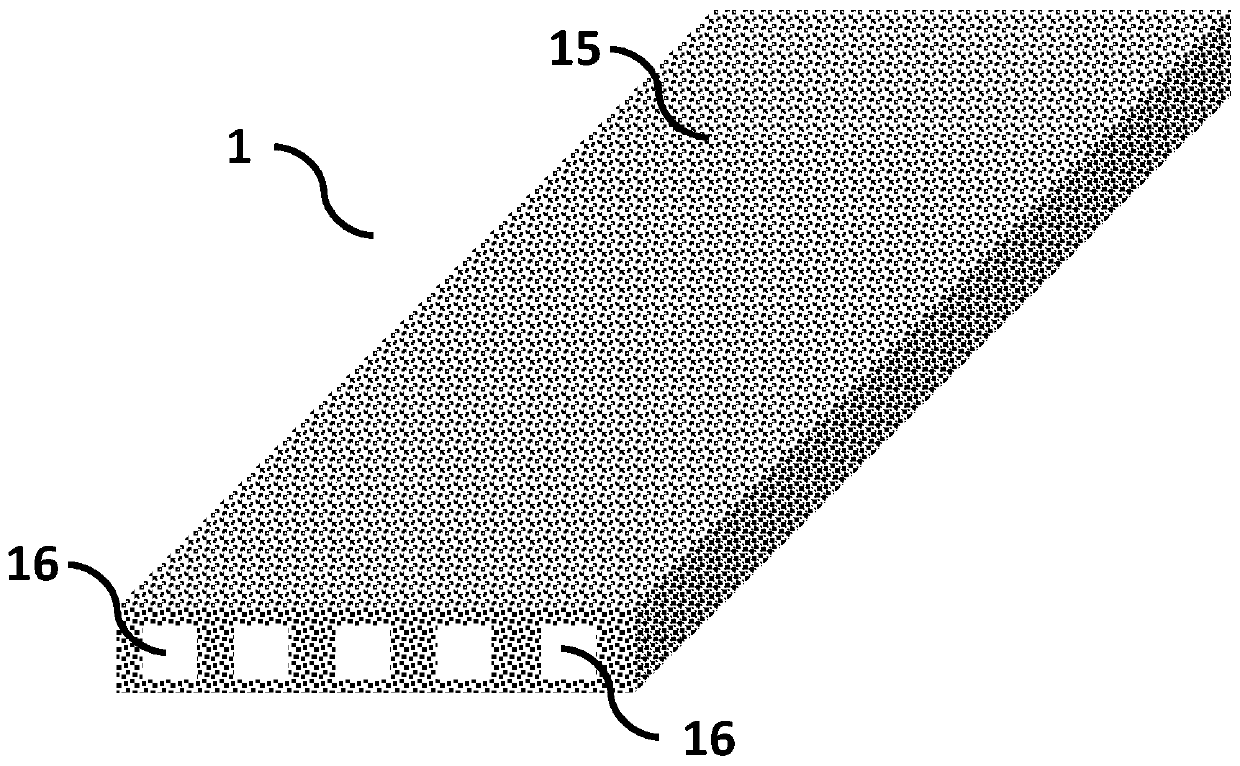

[0104] figure 1 A principal schematic diagram of a solar collector 1 is shown, wherein a composite material 15 is shown. As indicated, the composite material is a mixture of at least two components, or materials constituting the production material of the solar collector, as previously described. In a preferred embodiment, these materials are at least one polymer having the same modulus of elasticity as wood chips. However, those skilled in the art will appreciate that any material having the same or substantially the same modulus of elasticity can be used by those skilled in the art to produce the solar collectors disclosed herein. figure 1 Also shown is a hollow section 16, or channel 16, in which the media is stored, circulated or transported.

[0105] figure 1 Also shown is an example of how the collector body behaves during production in one embodiment, eg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com