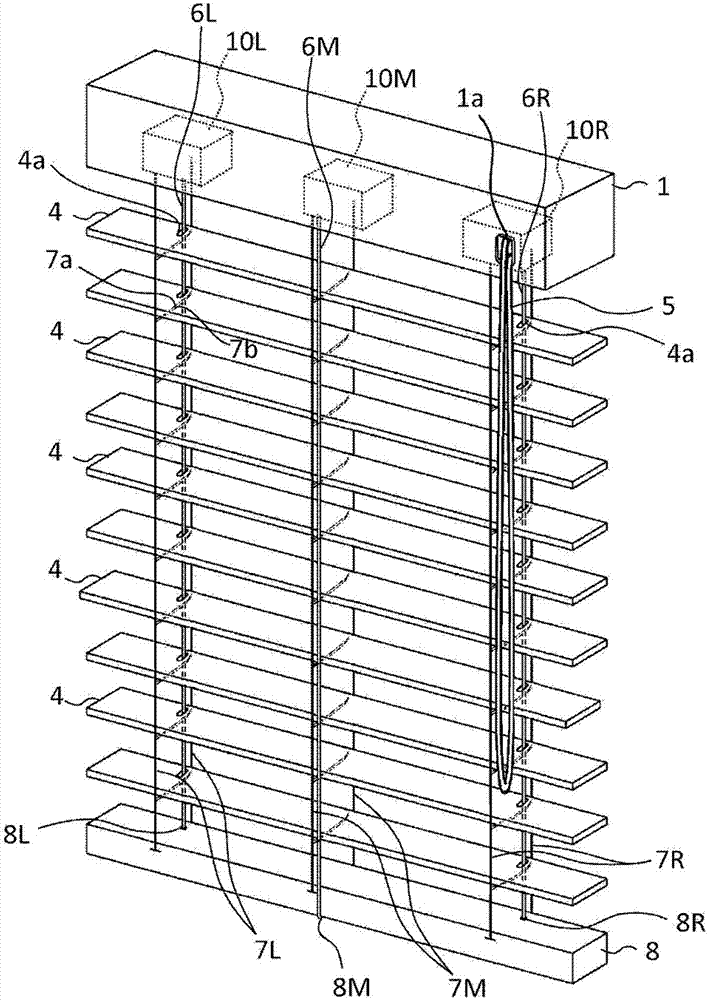

Horizontal blind

A shutter and horizontal technology, which is applied in the field of horizontal shutters, can solve the problems of increased resistance, jamming, and non-smoothness of lifting ropes and blades, and achieve the effect of improving the descending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

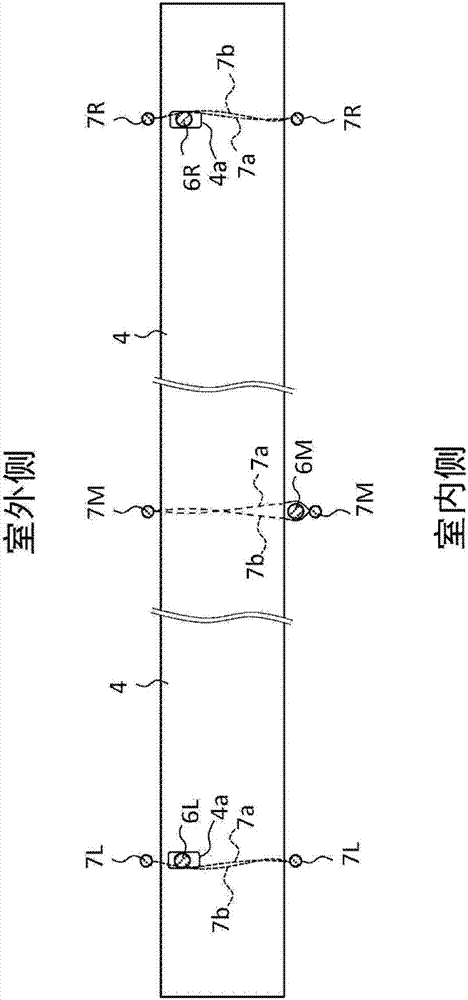

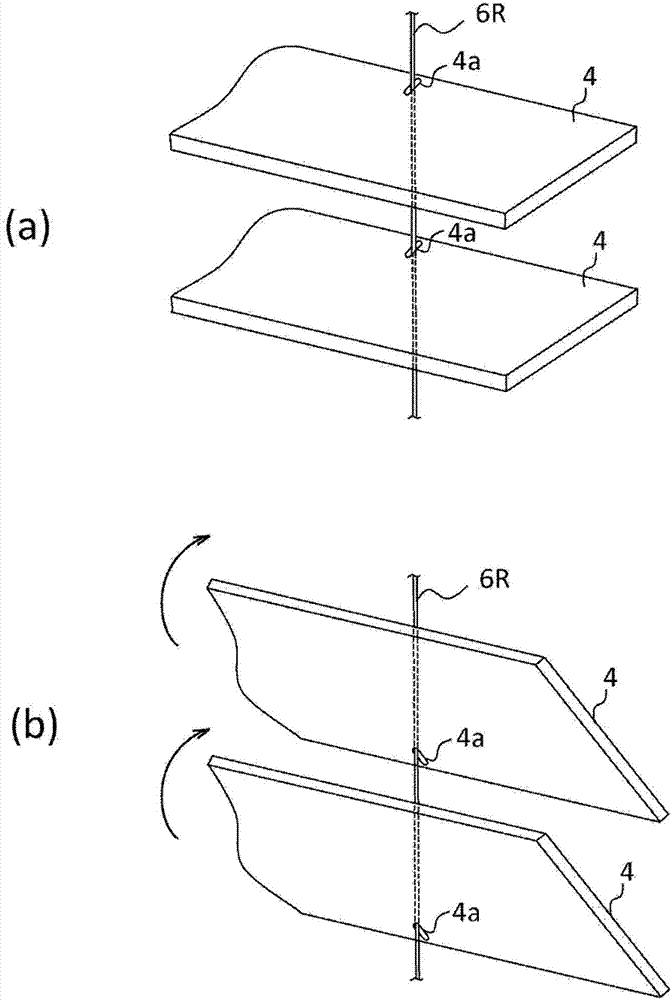

[0060] (the blade of embodiment 1)

[0061] Figure 4 (a), (b) are the partial plan view and sectional drawing which demonstrated the shape of the long hole shape insertion hole 4a of the vane|blade 4 of Example 1 in the horizontal blind of this embodiment. in addition, Figure 4 (c) is a partial side sectional view explaining the state when the lift cord 6L (or 6R) hangs down with respect to the blade 4 of Example 1. FIG.

[0062] Such as Figure 4 As shown in (c), in the blade 4 of Embodiment 1, the following configuration example is shown: that is, the position where the lifting cord 6L (or 6R) inserted into the insertion hole 4a hangs down from the winding shaft 11 is smaller than the When the insertion hole 4a is located substantially on the indoor side, the lifting cord 6L (or 6R) is brought into contact with the outdoor side guide surface of the diverting pulley 13L (or 13R) provided below the winding shaft 11 to hang down.

[0063] In order to improve the descendin...

Embodiment 2

[0066] (the blade of embodiment 2)

[0067] Figure 6 (a), (b) is a partial plan view and sectional drawing which demonstrate the shape of the long hole shape insertion hole 4a of the vane|blade 4 of Example 2 in the horizontal blind of this embodiment. in addition, Figure 6 (c) is a partial side sectional view explaining the state when the lift cord 6L (or 6R) hangs down with respect to the blade 4 of Example 2.

[0068] Such as Figure 6 As shown in (c), in the blade 4 of the second embodiment, the following configuration example is shown: that is, the position where the lifting cord 6L (or 6R) inserted into the insertion hole 4a hangs down from the winding shaft 11 is smaller than the When the insertion hole 4a is located substantially outside the room, the lifting cord 6L (or 6R) is brought into contact with the indoor side guide surface of the diverting pulley 13L (or 13R) provided below the winding shaft 11 to hang down.

[0069] Such as Figure 6 As shown in (b) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com