Bearing device for changing supporting force of steel framework of deep foundation pit according to soil covering amount

A load-bearing device and support device technology, which is applied in infrastructure engineering, construction, excavation, etc., can solve the problems of reducing the service life of steel skeletons, bearing loads, and increasing the strength of steel skeletons, so as to ensure normal use, ensure safety, The effect of improving the ability to undertake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

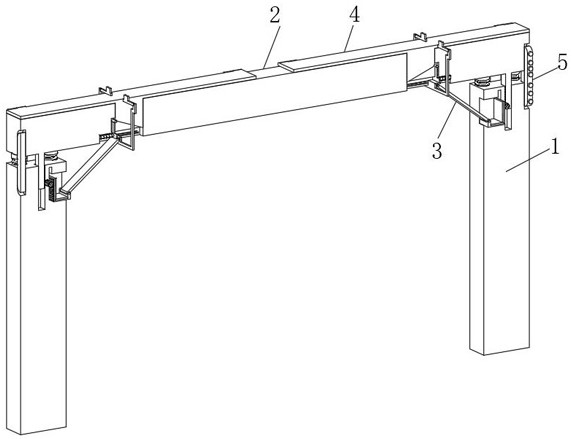

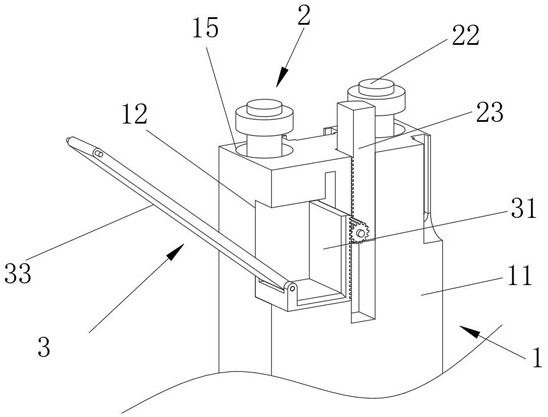

[0038] see Figure 1-Figure 10 As shown, the purpose of this embodiment is to provide a load-bearing device for changing the supporting force of the deep foundation pit steel skeleton according to the amount of soil covering, including two supporting devices 1 and a crossbeam 2 arranged at the upper ends of the two supporting devices 1, and the supporting device 1 1. The position where the crossbeam 2 is connected is provided with a load-bearing mechanism 3 for supporting the crossbeam 2. The support device 1 includes a support column 11. The four corners of the upper end of the support column 11 are provided with plug holes 15. The crossbeam 2 includes a crossbeam rod 21 and is fixed on the crossbeam rod. 21 several plug-in posts 22 at the bottom of both ends, a spring stop ring 26 is fixed on the plug-in post 22, an anti-compression spring 29 with one end fixed on the spring stop ring 26 is sleeved on the plug-in post 22, and the anti-compression spring 29 One end of the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com