Pneumatic tire

A pneumatic tire, tire circumferential technology, applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., to improve wear resistance, fully maintain wear resistance, and relieve stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

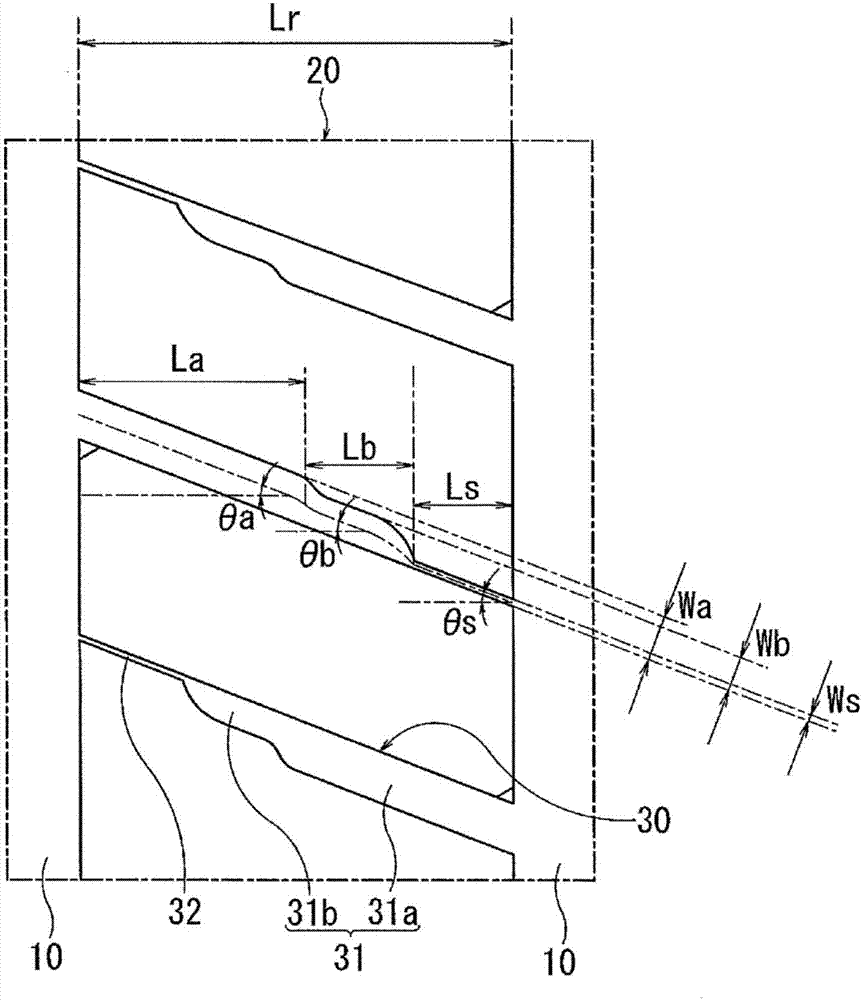

[0056] When the tire size is 215 / 60R16, with figure 1 The reinforcement structure exemplified in and except for the composite groove (and the circumferential auxiliary groove) are figure 2 In tires based on the tread pattern of , the structure of the composite groove, the ratio of the groove width of the composite groove (ratio Wa / Wb, ratio Wb / Ws), the ratio of groove length (ratio La / Lr, ratio Lb / Lr, ratio Ls / Lr), the presence or absence of circumferential narrow grooves, and the groove width of circumferential narrow grooves, 15 kinds of pneumatic tires including Conventional Example 1, Comparative Examples 1 to 3, and Examples 1 to 11.

[0057] In these 15 kinds of pneumatic tires, except for Conventional Example 1, Comparative Examples 1-2, and Example 4, the shape of the composite groove is common to image 3 the shape shown. That is, each composite groove includes a transverse groove whose one end communicates with the main groove on one side and the other end termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com