Card locked pull-fall separation electrical connector

A technology of electrical connectors and locks, which is applied in the direction of connection and connection device components, circuits, etc., can solve the problems of easy jamming, large size, poor reliability, etc., and achieve easy pull-off and loose, simple and reliable operation , The effect of simple part structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further description will be made below in conjunction with drawings and embodiments.

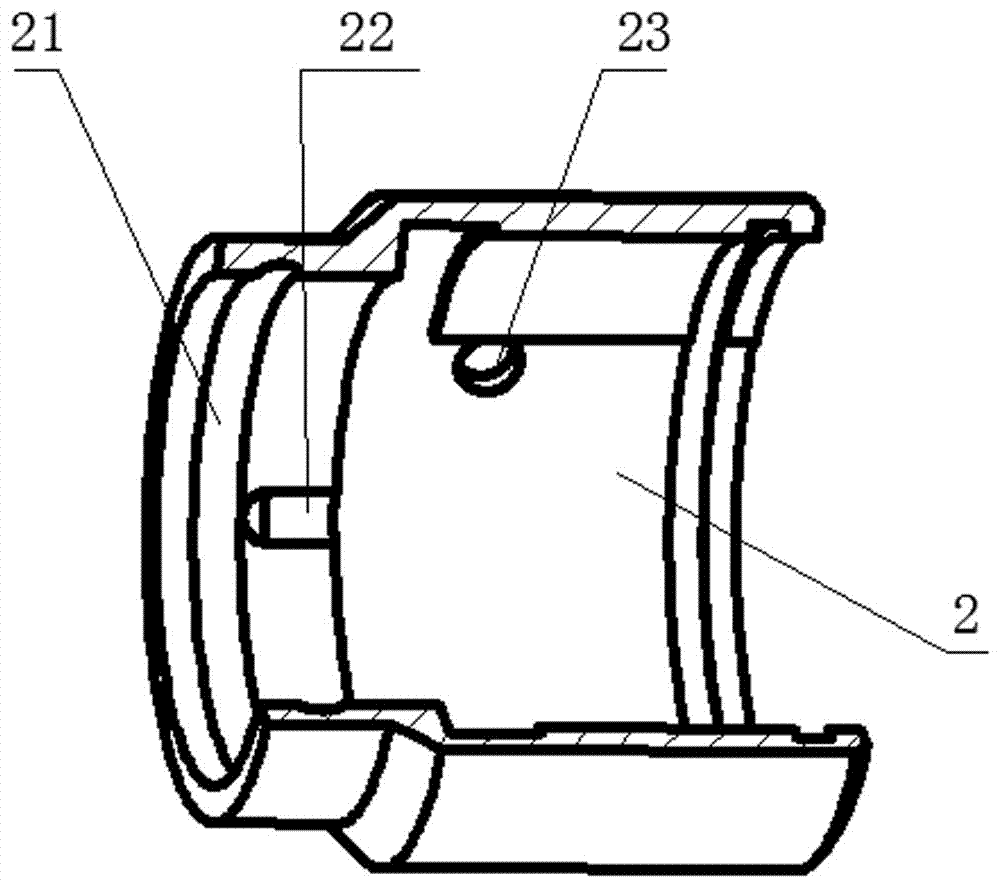

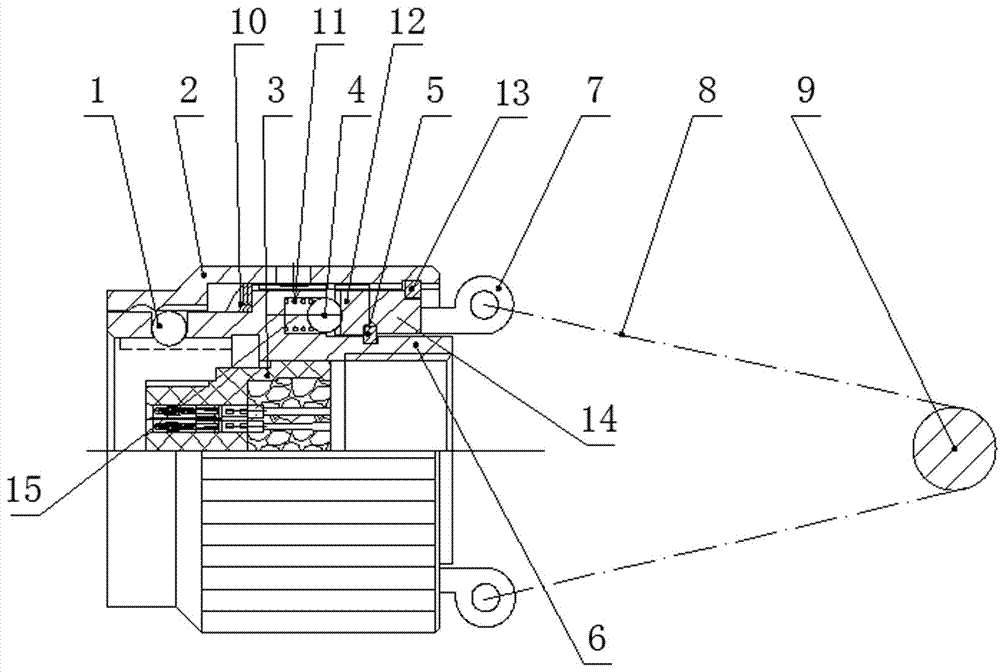

[0016] figure 1 , 2 Shown: a snap-lock type pull-off separation electrical connector includes a plug and a socket ( figure 2 not shown in ), the outer wall of the front part of the head shell 6 of the plug is provided with more than one locking steel ball 1 for locking the connection plug and socket, the hole core assembly 3 is arranged inside the head shell 6, and the locking sleeve 2 is socketed Outside the head housing 6, the locking sleeve is provided with a state identification 23 radially corresponding to the position mark on the head housing, and the inner wall of the front part of the locking sleeve 3 is provided with a circle of circumferential grooves 21 and more than one axial direction from outside to inside. Groove 22, the middle part of the inner wall of the locking sleeve 3 is elastically pressed against the front end of the outer wall of the head housing 6 via the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com