A high-temperature sintering ore reclaiming method and reclaiming device thereof

A technology of high-temperature sintering and reclaiming device, applied in charge, furnace, charge control and other directions, can solve the problems of time-consuming, low PC cross-accuracy detection, etc., and achieve the effect of flexible switching, simple structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better understand the above-mentioned technical solution of the present invention, a further detailed description will be given below in conjunction with the accompanying drawings and embodiments.

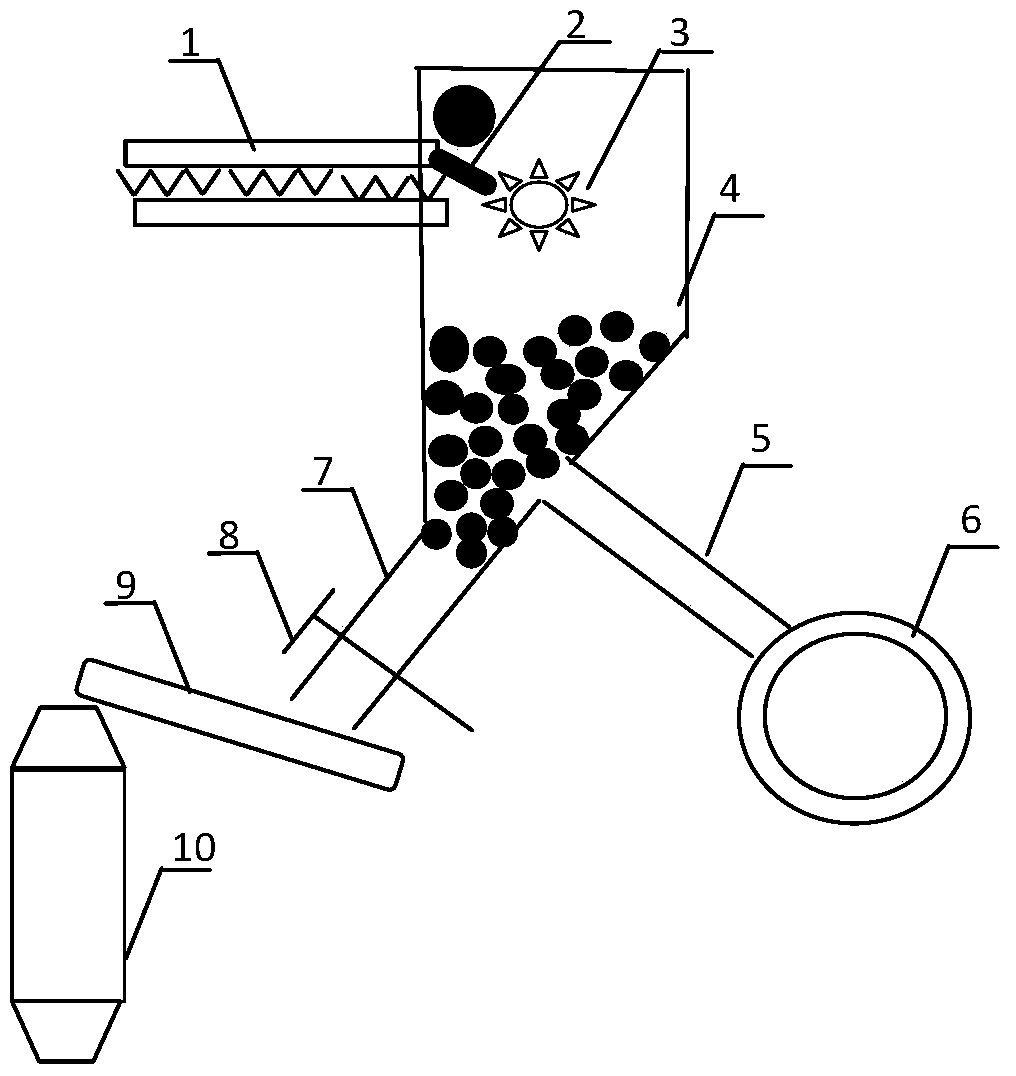

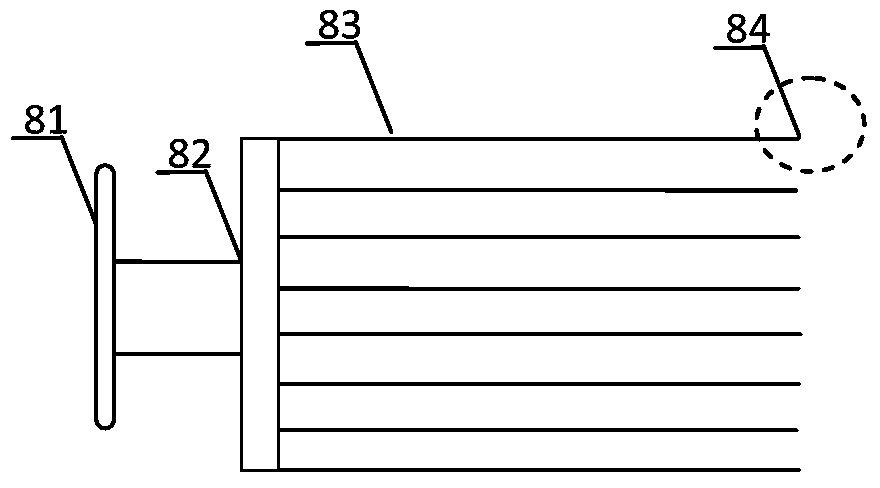

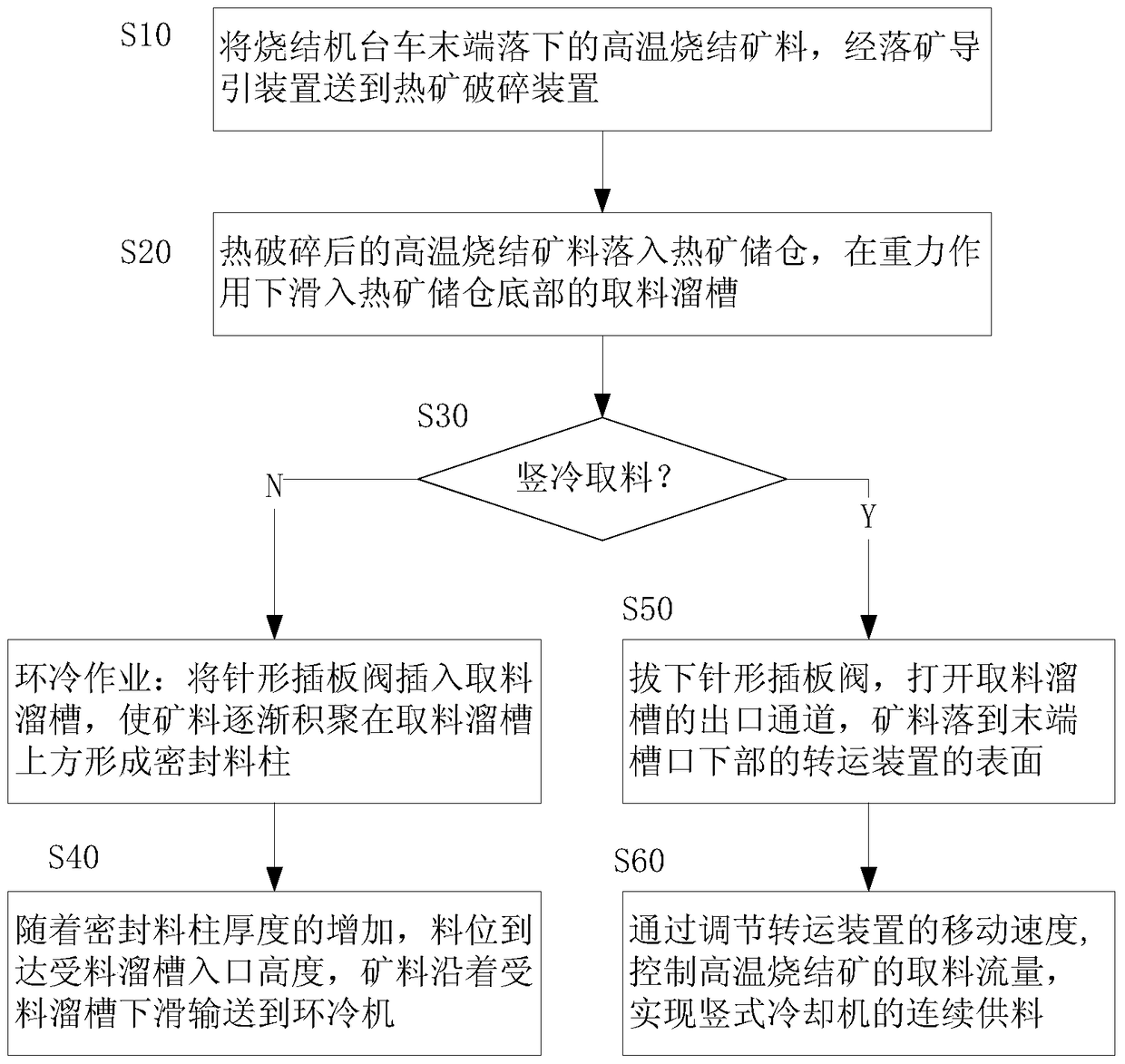

[0037] The high-temperature sinter reclaiming method of the present invention is used for the high-temperature sinter reclaiming operation of the sinter sensible heat recovery system, and is characterized in that, at the bottom of the hot ore storage bin 4 of the reclaiming device, a vertical cooler is set to feed the material The reclaiming chute 7 of 10; on the side wall of the hot ore storage bin 4 of the reclaiming device, the receiving chute 5 feeding to the annular cooler 6 is set; the inlet of the receiving chute 5 is higher than the inlet of the reclaiming chute 7 , the high-temperature sintered ore material that enters the hot ore storage bin 4 slides preferentially into the reclaiming chute 7 under the action of gravity; The needle-shaped gate valve 8 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com