Continuous circulation drilling system and method

A technology of drilling and normal circulation, which is applied in drilling equipment and methods, drilling equipment, earthwork drilling and production, etc. It can solve the problems of pump stuck, cuttings sinking, overflow and lost circulation, etc., and avoid borehole wall Loss of stability, elimination of influence, and the effects of avoiding lost circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

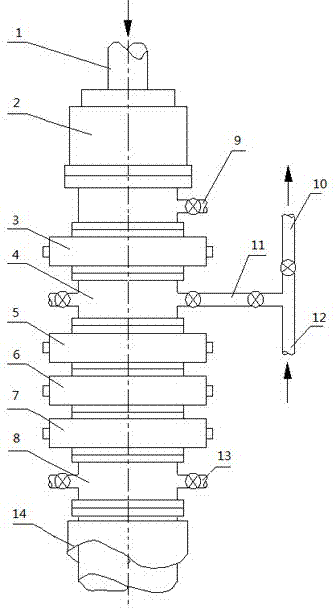

[0015] refer to figure 1 , a continuous circulation drilling system, including a drilling tool 1, a rotating blowout preventer 2 sequentially connected from top to bottom, a normal circulation outlet manifold 9, a fully sealed blowout preventer 3, an upper cross 4, and an anti-rotation hanger 5 , Inverted semi-sealed blowout preventer 6, semi-sealed blowout preventer for well control blowout prevention 7, lower cross 8 and casing head 14, and high pressure side circulation manifold 11 connected to upper cross 4, riser manifold 10. The high-pressure pipeline 12 and the throttling manifold 13 connected to the lower cross 8.

[0016] According to the continuous circulation drilling method of the aforementioned continuous circulation drilling system, the implementation steps are as follows:

[0017] In the normal positive circulation during norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com