A box girder assembly and welding equipment

A technology for welding equipment and box beams, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor intensity, slow progress and high risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The above-mentioned features and advantages of the present invention can be better understood after reading the detailed description of the embodiments of the present disclosure in conjunction with the following drawings. In the drawings, components are not necessarily drawn to scale, and components with similar related properties or characteristics may have the same or similar reference numerals.

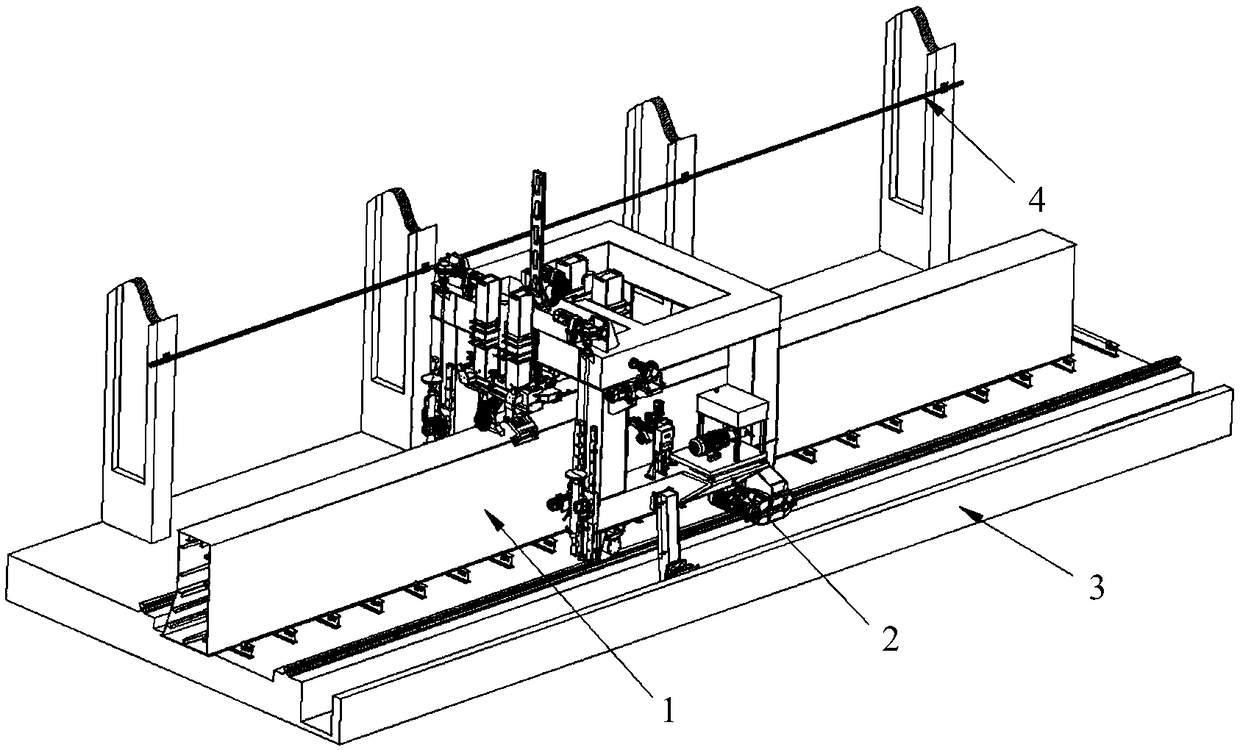

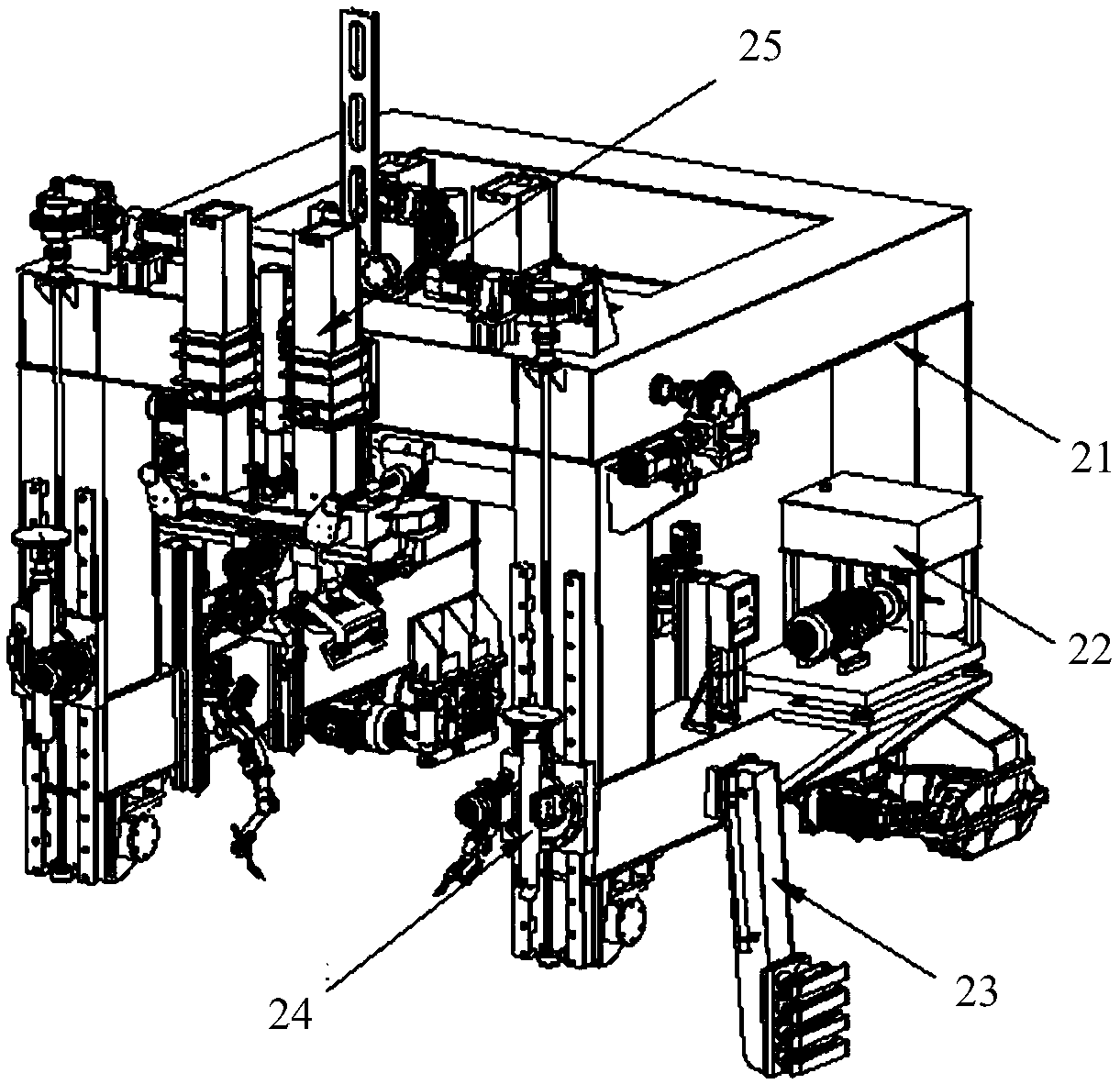

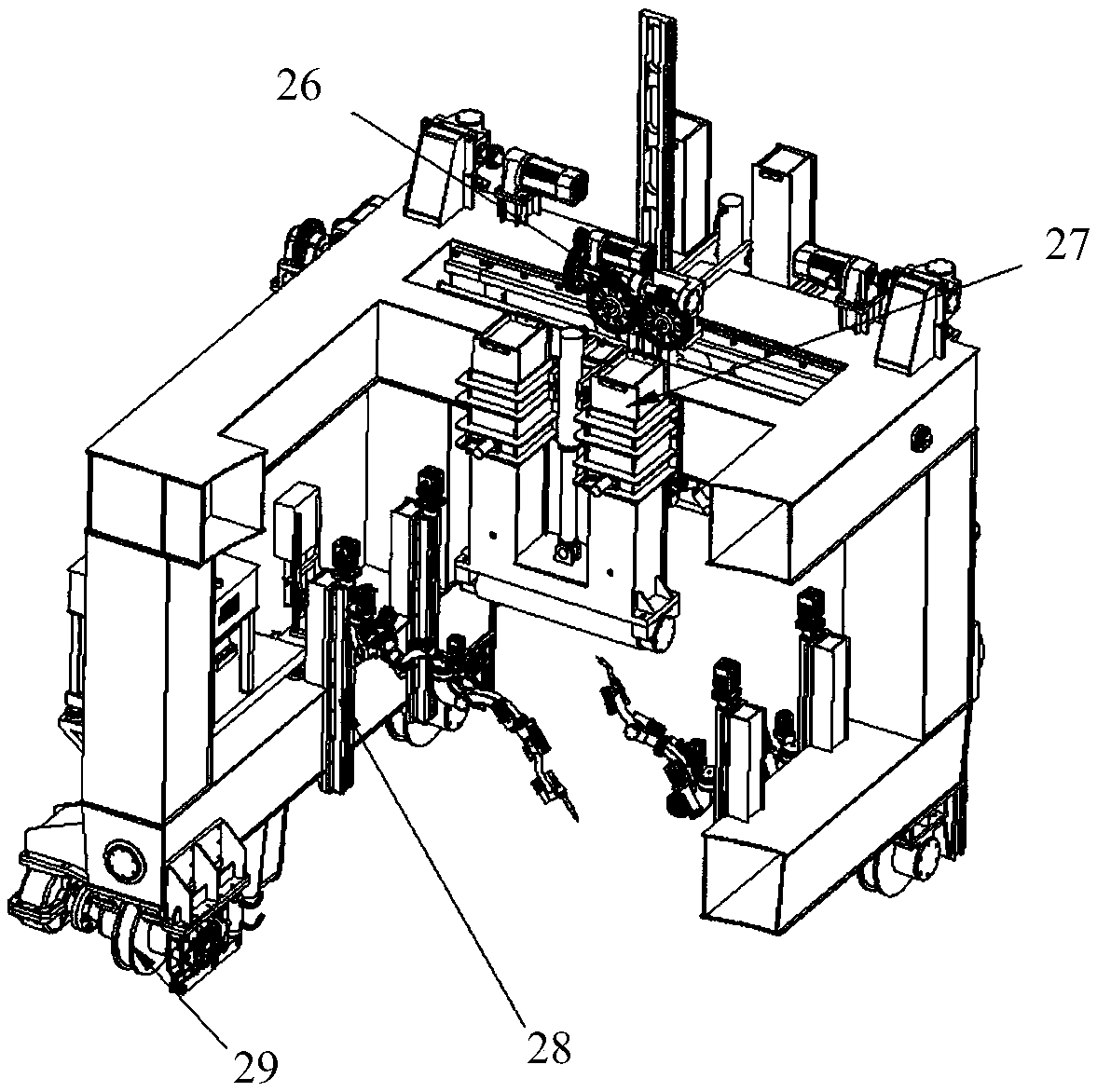

[0064] figure 1 It shows the working site and the working state of the box girder assembly welding equipment of the present invention. The box girder 1, the distance scale 4 and the box girder assembly welding equipment 2 are placed on the bottom plate 3. The specific structure of the box girder assembly and welding equipment 2 is as follows: Figure 2A with 2B As shown, it includes main frame 21, hydraulic station 22, trolley line device 23, web jacking and driving system 24, inner partition alignment and fixing system 25, internal welding manipulator and driving system 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com