Medium/high-pressure fine water mist nozzle with wind resistance and wind resistance application method thereof

A technology of fine water mist nozzle and application method, which is applied in fire rescue and other directions, can solve the problems of inability to solve the problem of nozzle wind resistance, and cannot improve the effective atomization cone angle, so as to achieve good overall fire extinguishing performance, improve wind resistance performance, The effect of improving the application ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

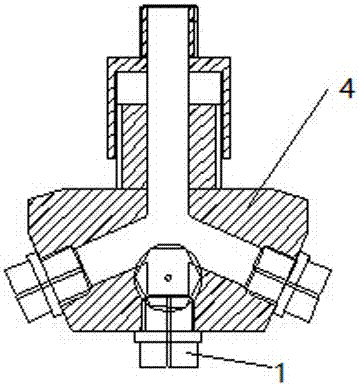

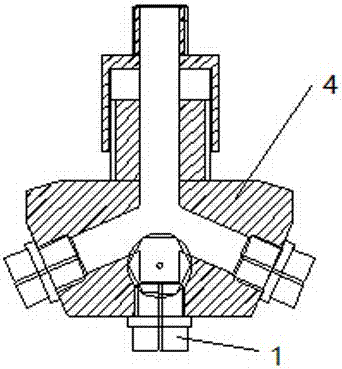

[0039] see figure 1 with figure 2 , the medium-high pressure fine water mist nozzle of the present embodiment adopts the showerhead type nozzle housing 4, and 7 fine water mist nozzles are arranged on the nozzle housing 4, wherein one nozzle sprays along the axial direction of the showerhead type nozzle housing, and the remaining 6 The nozzles are sprayed along the side of the shower head housing, and the side sprayed fine water mist nozzles are evenly distributed around the axial sprayed fine water mist nozzles. Each fine water mist nozzle is threadedly connected to the nozzle housing, and the inner cavity of the nozzle housing communicates with the inner cavity of each fine water mist nozzle. In this embodiment, the axial spray fine water mist nozzle adopts the first swirl fine water mist nozzle 1 ( Figure 7 with Figure 8 shown), the atomization cone angle is 55°, and the flow coefficient K is 1.5. The water mist nozzle for lateral injection adopts the second swirl wa...

Embodiment 2

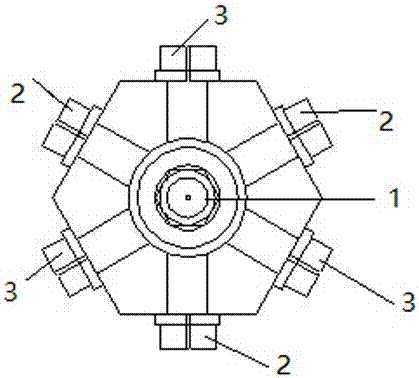

[0041] see image 3 with Figure 4 , the medium-high pressure fine water mist nozzle of the present embodiment adopts the showerhead type nozzle housing 4, and 7 fine water mist nozzles are arranged on the nozzle housing 4, wherein one nozzle sprays along the axial direction of the showerhead type nozzle housing, and the remaining 6 The nozzles are sprayed along the side of the shower head housing, and the side sprayed fine water mist nozzles are evenly distributed around the axial sprayed fine water mist nozzles. Each fine water mist nozzle is threadedly connected to the nozzle housing, and the inner cavity of the nozzle housing communicates with the inner cavity of each fine water mist nozzle. In this embodiment, the axial spray fine water mist nozzle adopts the first swirl fine water mist nozzle 1 ( Figure 7 with Figure 8 shown), the atomization cone angle is 55°, and the flow coefficient K is 1.5. The water mist nozzle for side jetting adopts the first swirl water mi...

Embodiment 3

[0043] see Figure 5 with Image 6 , the medium and high pressure water mist nozzle of the present embodiment adopts a showerhead type nozzle housing 4, and 7 fine water mist nozzles are arranged on the nozzle housing 4, wherein one fine water mist nozzle sprays along the axial direction of the showerhead type nozzle housing, The other 6 fine water mist nozzles are sprayed along the side of the shower head housing, and the lateral sprayed fine water mist nozzles are evenly distributed around the axial sprayed fine water mist nozzles. Each fine water mist nozzle is threadedly connected to the nozzle housing, and the inner cavity of the nozzle housing communicates with the inner cavity of each fine water mist nozzle. The axial spray fine water mist nozzle adopts direct spray fine water mist nozzle 3 ( Figure 11 with Figure 12 shown), the atomization cone angle is 30°, and the flow coefficient K is 1.0. Two kinds of water mist nozzles, direct jet and swirl, are uniformly cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com