Control method for steel plate performance optimization

A control method and steel plate technology, applied in the field of steel rolling control, can solve problems such as poor precision and complex calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

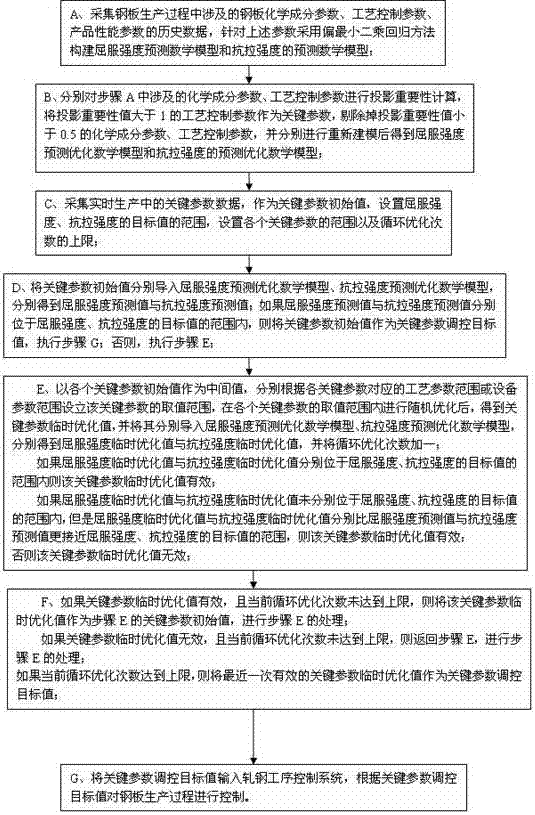

[0060] Such as figure 1 As shown, this embodiment is represented by the SS400 steel plate with a thickness of 16 mm as a typical hot-rolled product, and the control method for optimizing the performance of the steel plate provided includes the following steps:

[0061] A. Collect the historical data of steel plate chemical composition parameters, process control parameters, and product performance parameters involved in the production process of SS400 steel plates, and use the partial least squares regression method to construct a predictive mathematical model for yield strength and tensile strength for the above parameters;

[0062] Described partial least square regression method builds the method for mathematical model as follows:

[0063] a. Standardize the independent variable matrix X=[x1,...,xp]n*p (p=19) composed of chemical composition parameters and process control parameters to obtain matrix variable E0=[E01,...,E0p]n* p; Standardize the dependent variable matrix Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com