Geometric accuracy on-line monitoring method of numerical control machine tool

A technology of geometric precision and CNC machine tools, which is applied in the field of CNC machine tools, can solve the problems of long-term geometric precision of CNC machine tools, and achieve the effects of small space occupation, high measurement accuracy and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

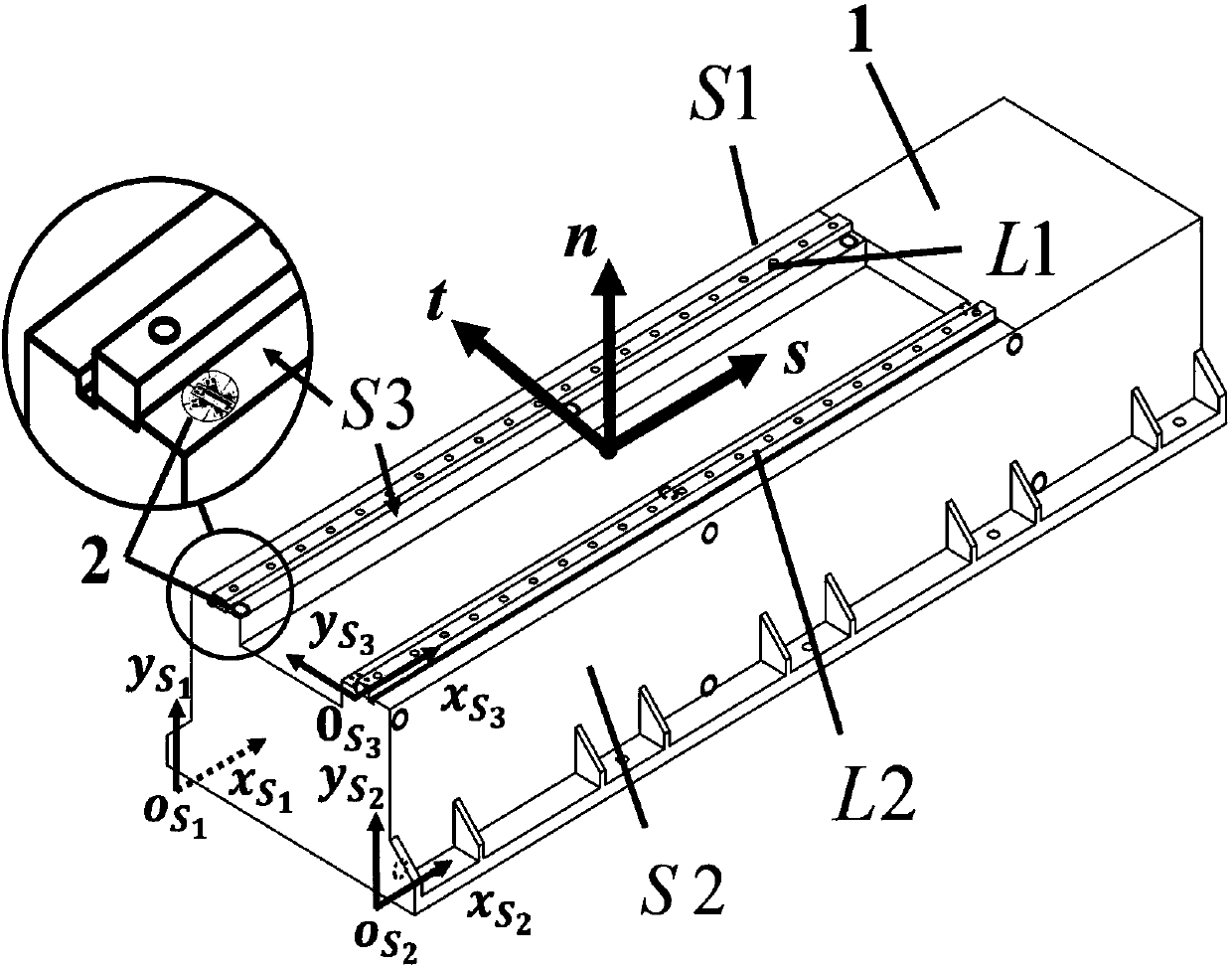

[0042] The CNC machine tool under test is a bed of a vertical machining center, the length of the guide rails L1 and L2 is 1060mm, the inner distance between the guide rails L1 and L2 is 770mm, and the height of the bed is 550mm.

[0043] Step 1 Arrangement of strain measuring points

[0044] On the upper and lower edges of the first side surface S1 of the CNC machine tool bed 1, the upper and lower edges of the second side surface S2, and the edges of the inner sides of the two guide rails on the upper surface S3, the strain gauges are evenly pasted, the number of strain gauges on each surface, k=[(1060 / 250)+3]=3. The distance between adjacent strain gauges of the first side surface S1 , the second side surface S2 , and the upper surface S3 along the rail direction s is d=(2×1060) / (6-2)=530. The middle sensitive grid of the strain gauge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com