System and method for detecting effective prestressing force under anchor by adopting method for detecting and stabilizing clamping piece displacement

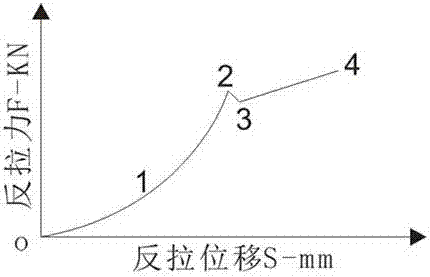

A detection system and prestressing technology, applied in the direction of measuring devices, force/torque/power measuring instruments, instruments, etc., can solve the problems that the clip cannot return to the original position, it is difficult to ensure the detection accuracy, and the test results are large, etc., to achieve Improved test range, easy operation, and large test range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

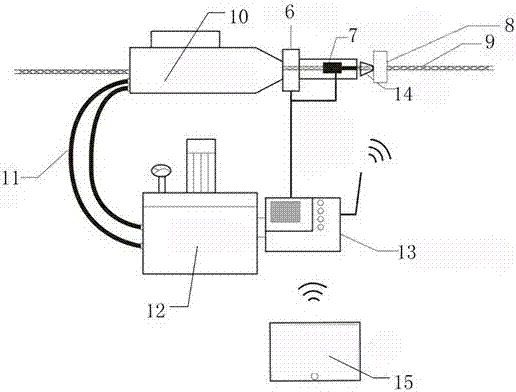

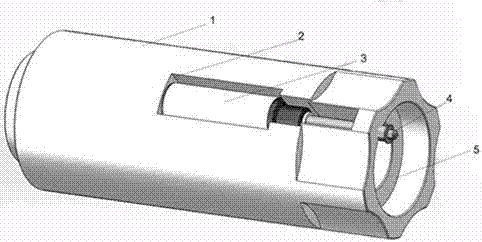

[0036] like figure 2 and image 3As shown, a system and method for detecting the effective prestress under the anchor by detecting and stabilizing clip displacement, it includes a detection system and a detection method, and the detection system includes a computer control center 15, a measurement control terminal 13, an oil pump 12. Jack 10, force sensor 6, displacement measurement tooling 7, anchor head 8 and steel strand 9, the computer control center 15 is connected to the measurement control terminal 13 through the network or transmission cable and also connected to the oil pump 12, the measurement control terminal 13 is respectively connected with the force sensor 6, the displacement measuring tool 7 and the oil pump 12 through the signal cable, and the oil pump 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com