Method and device for detecting dual-axis horizontal precision

A horizontal accuracy and measuring device technology, applied in the field of measurement, can solve the problems of low reading efficiency, real-time display, limited measurement space, and inability to measure dual-axis horizontal accuracy at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

[0035] According to a specific embodiment of the present invention, a method for detecting biaxial horizontal accuracy is disclosed, comprising steps:

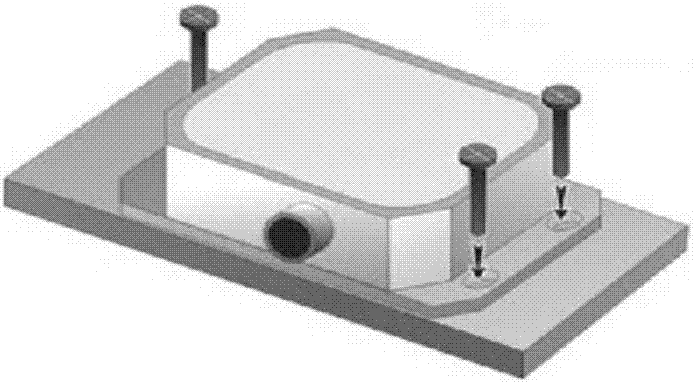

[0036] S1. Under harsh conditions such as narrow measurement space and high measurement reference surface, select measurement components according to the leveling accuracy requirements of the measured object and the installation conditions of the measurement reference surface;

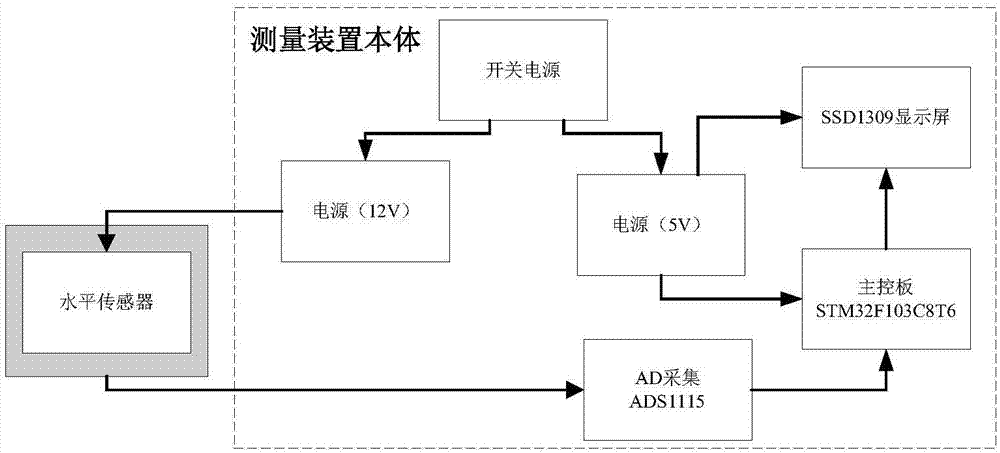

[0037] The measuring components include a level sensor, an AD acquisition unit, a main control board, a display screen, a first power supply, a second power supply and a power switch.

[0038] Further, steps are also included b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com