Full-scale range infrared gas detector and measuring method thereof

A gas detector, full-range technology, applied in the direction of measuring devices, color/spectral characteristic measurement, instruments, etc., can solve the problem that infrared gas detectors cannot achieve full-range measurement, it is difficult to meet the use requirements of the same gas, and the resolution is difficult to meet the actual situation Needs and other issues, to achieve the effect of simple and practical measurement method, ingenious design and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be further described in detail below through specific embodiments.

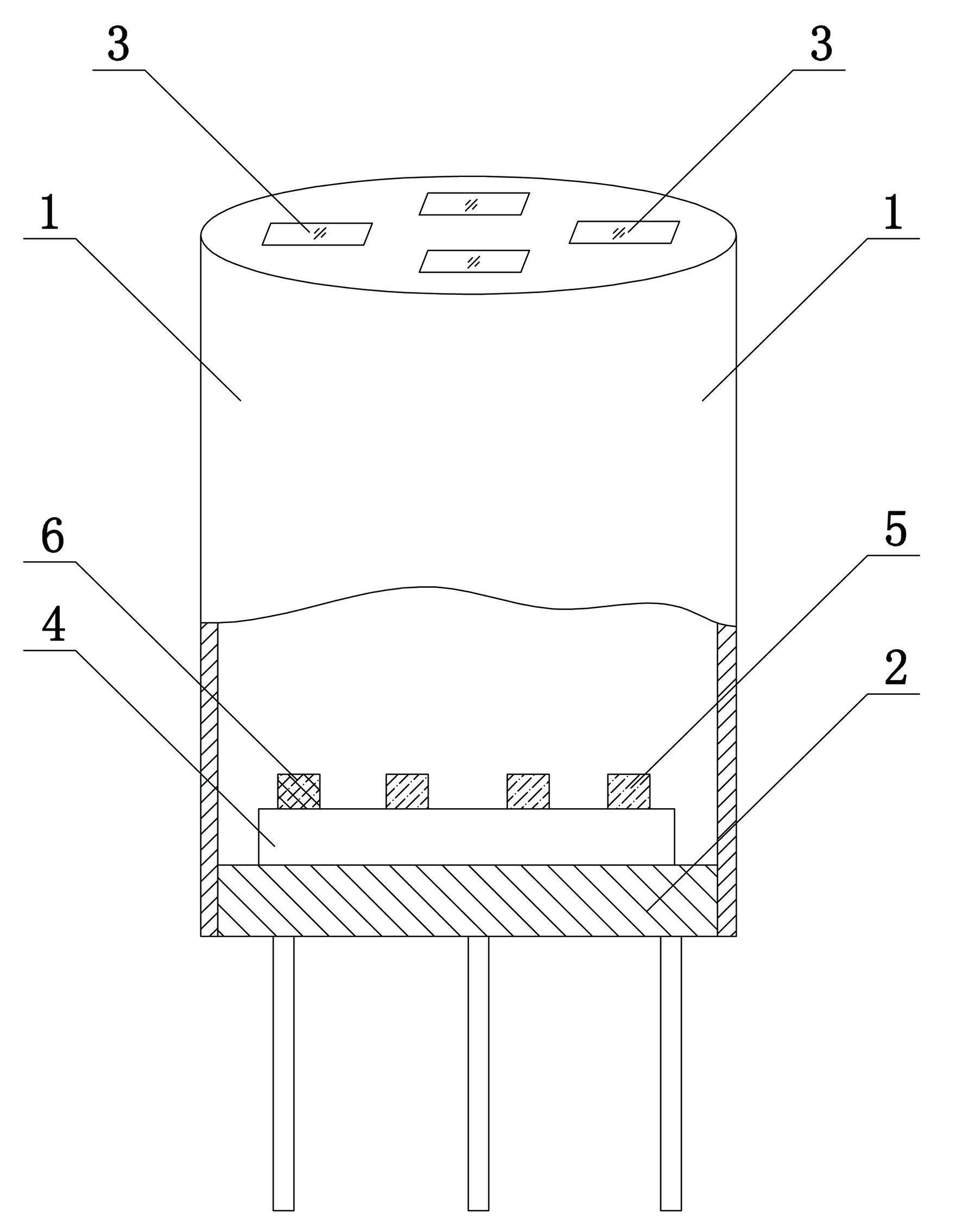

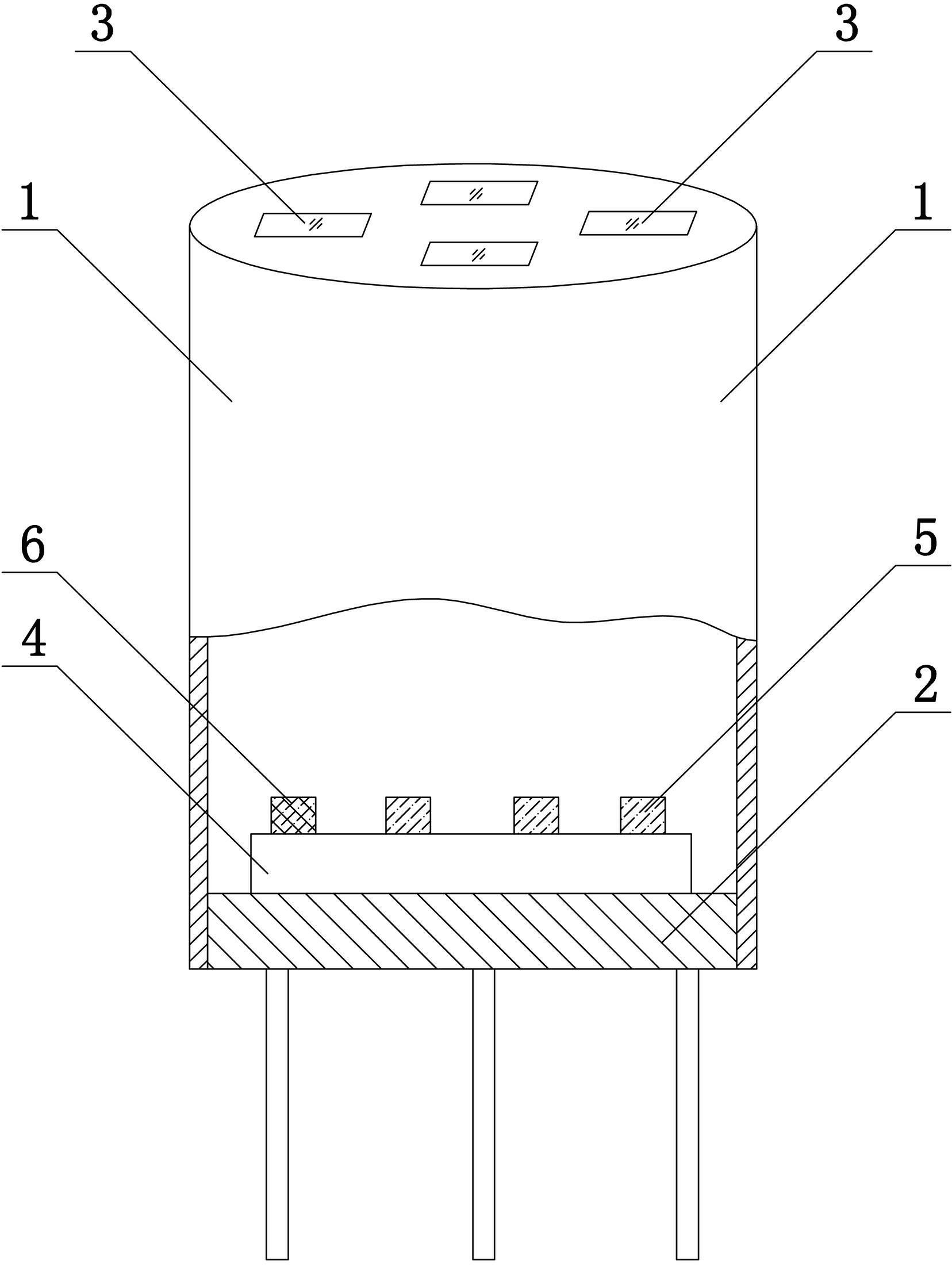

[0013] like figure 1 As shown, a full-scale infrared gas detector includes a metal casing 1 provided with a filter 3 and a base 2 provided with a detector 4. The metal casing 1 and the base 2 are in an inert gas environment. packaged together, wherein, N+1 filters 3 with different wavelengths are arranged on the metal casing 1, and the detector 4 includes a reference thermopile chip 6 and N identical measurement thermopile chips 5 , wherein, the first filter 3 and the reference thermopile chip 6 form a reference channel, and the remaining N filters 3 correspond to the N measurement thermopile chips 5 one-to-one and form N measurement channels; N is greater than 3 is a natural number.

[0014] Specifically, in this embodiment, the metal casing 1 is provided with four filters 3 of different wavelengths, and the detector 4 includes a reference thermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com