Carrier roller rotation resistance measuring device

A technology of rotating resistance and measuring device, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problem of inaccurate numerical value of rotating resistance, and achieve the effect of satisfying measurement, ensuring vertical relationship and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

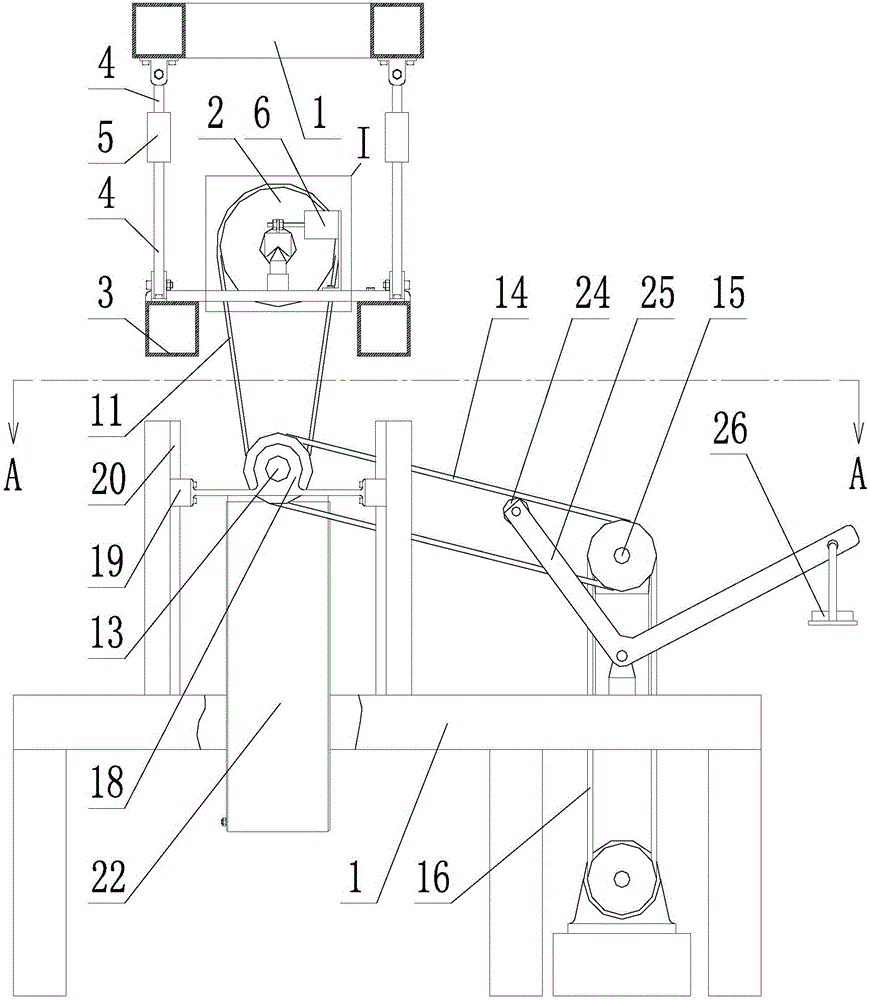

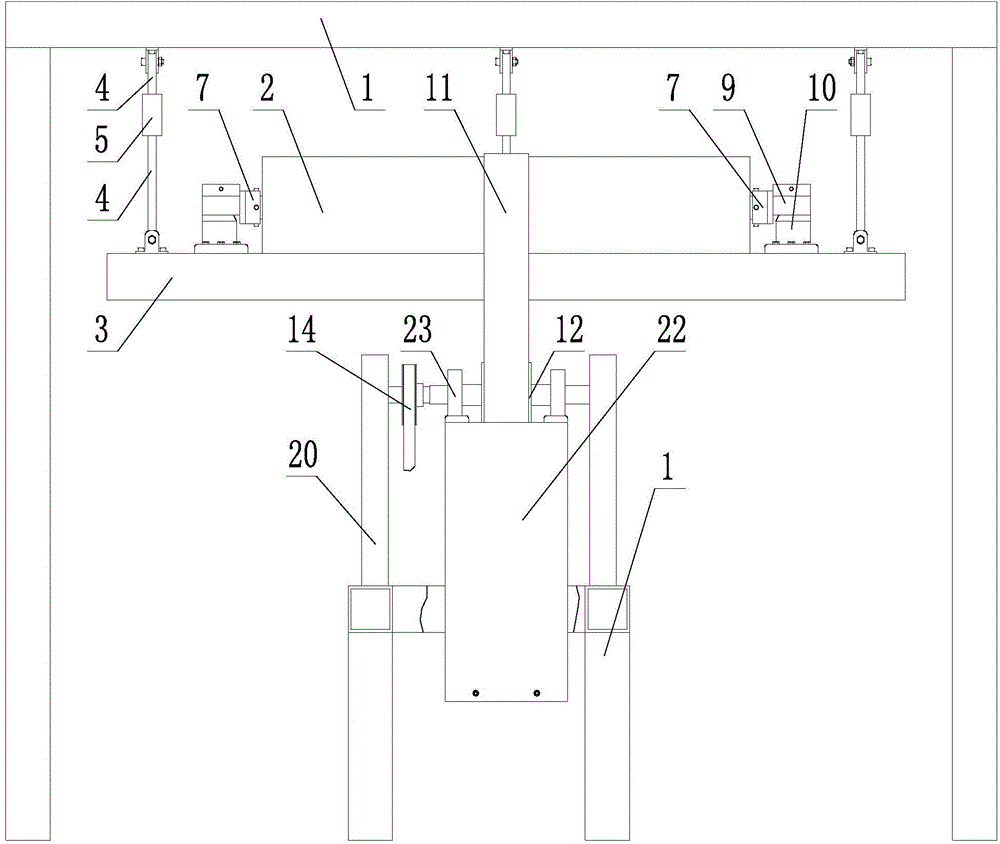

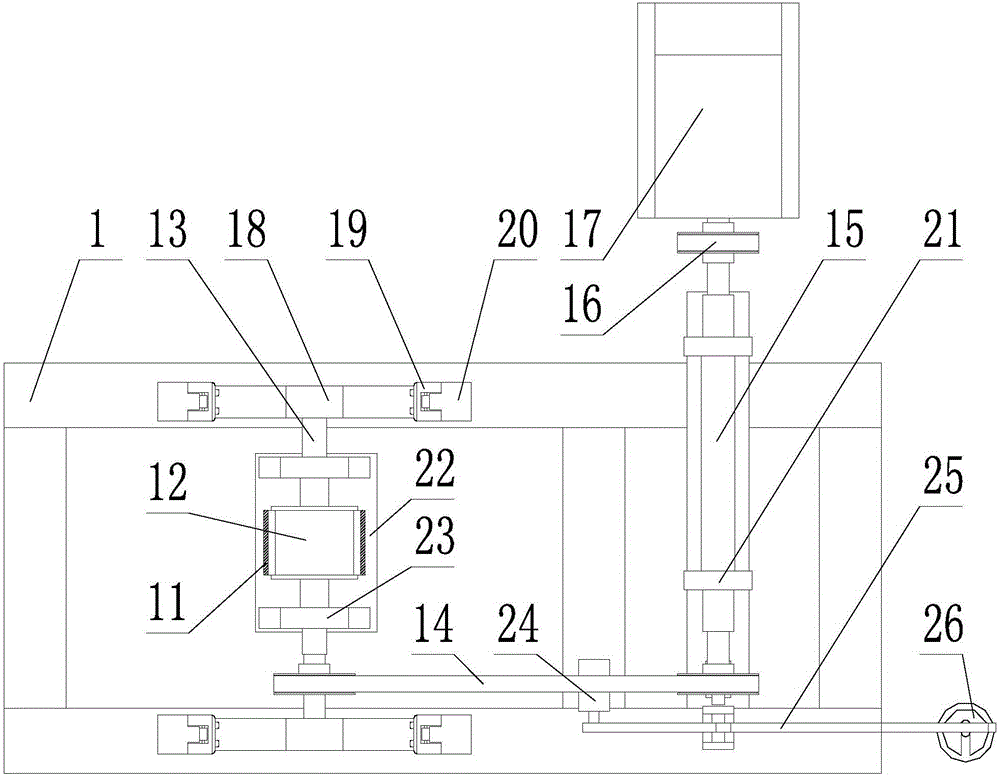

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as figure 1 , 2 , 3, 4, 5, and 6, a measuring device for idler rotation resistance, including a frame 1, a suspended idler measuring assembly and an idler drive assembly, the suspended idler measuring assembly includes an idler 2. Roller installation frame 3, boom 4, column tension sensor 5, S-type load cell 6, the idler 2 is horizontally arranged on the idler installation frame 3 through the first bearing seat 7, the S-type The load cell 6 is erected above the idler mounting frame 3, and one end of the S-type load cell 6 is fixedly connected to the first bearing seat 7 through the lever arm 8; the idler mounting frame 3 is suspended on the frame 1 On the top, the column tension sensor 5 is located between the upper and lower suspension points, and the column tension sensor 5 is connected to the upper and lower suspensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com