Construction method for penetrating through large-scale vertical karst cave group tunnel

A tunnel construction and karst cave technology, which is applied to tunnels, tunnel linings, shaft equipment, etc., can solve the problems of long treatment process, high consumption of manpower and material resources, and difficult construction, so as to eliminate the hidden danger of high-pressure karst water and shorten the construction period , The effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in combination with specific embodiments.

[0021] A construction method for tunnels passing through large vertical karst cave groups, the specific implementation steps are as follows:

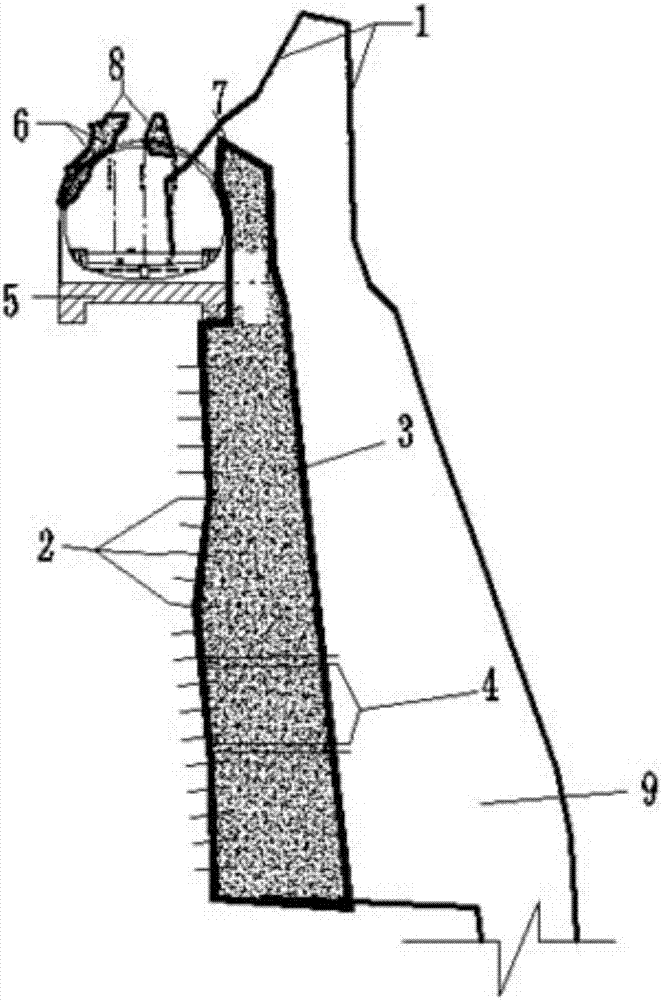

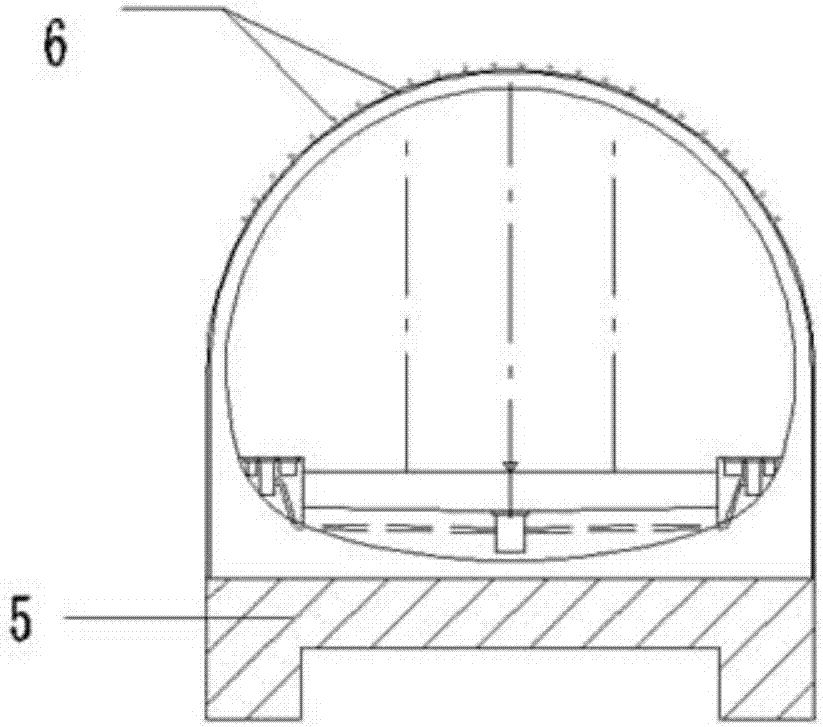

[0022] Step 1. Remove the dangerous rockfall existing locally on the rock wall of the karst cave, and use sprayed C20 surface protection concrete 1 for protection, expand and excavate the section at the vertical karst cave entrance as a working channel, and later use it as an inspection cave.

[0023] Step 2. The large-scale vertical karst cave group adopts backfill-based treatment measures. For the platform above the vertical karst cavity about 48m above the tunnel face, C20 backfill concrete 3 is used for pouring and backfilling, and the water passage 9 is reserved, and the backfilling concrete 3 is poured. Anchor rods 2 are embedded in the rock mass before the surrounding rock walls to increase the integrity of the backfill concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com