Hanging basket structure used in construction of reinforced concrete arch bridge

A reinforced concrete and construction process technology, applied in bridge construction, construction, bridges, etc., can solve the problems of hanging basket offset, large orifice size, time-consuming and laborious, etc., to achieve the effect of simple device structure and prevention of lateral deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

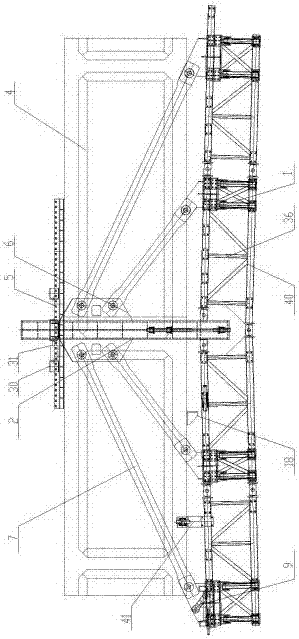

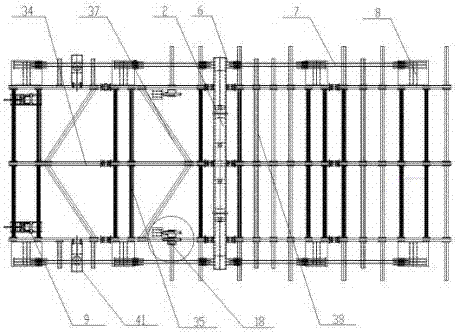

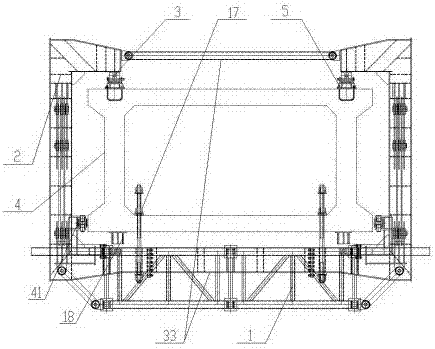

[0027] Embodiment of the present invention: a hanging basket structure used in the construction process of a reinforced concrete arch bridge, as attached Figure 1-11As shown, it includes a main truss load-bearing system 1, and a pair of C-shaped hooks 2 are installed on the left and right sides of the middle of the main truss load-bearing system 1. The top of the C-shaped hook 2 is connected to the running device 3, and the bottom of the running device 3 is located in the poured segment. On the walking track 5 on the top of the arch box 4, the C-shaped hook 2 is provided with a connecting plate 6, and the left and right sides of the connecting plate 6 are respectively connected to the front basket and the rear basket side of the main truss load-bearing system 1 through a plurality of cable-stayed sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com