Automatic conveying device used for electronic product detection

A technology for automatic conveying devices and electronic products, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of affecting detection accuracy, high energy consumption, and large manual labor, so as to improve the detection effect and detection accuracy, The effect of moving up and down smoothly and moving left and right

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

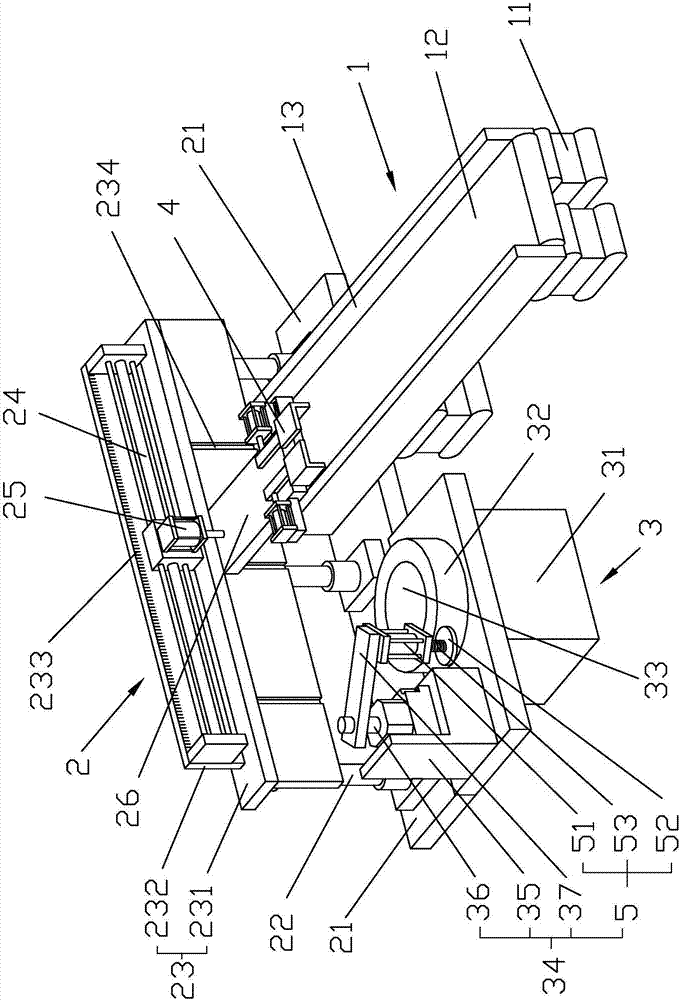

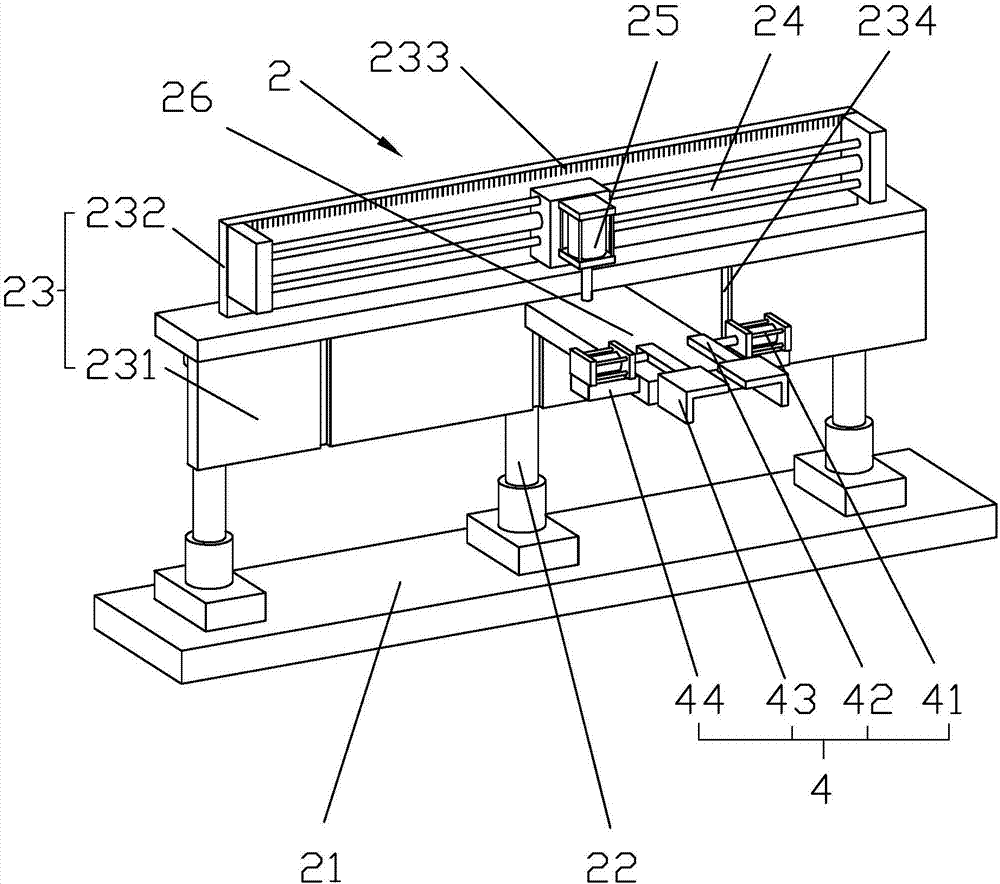

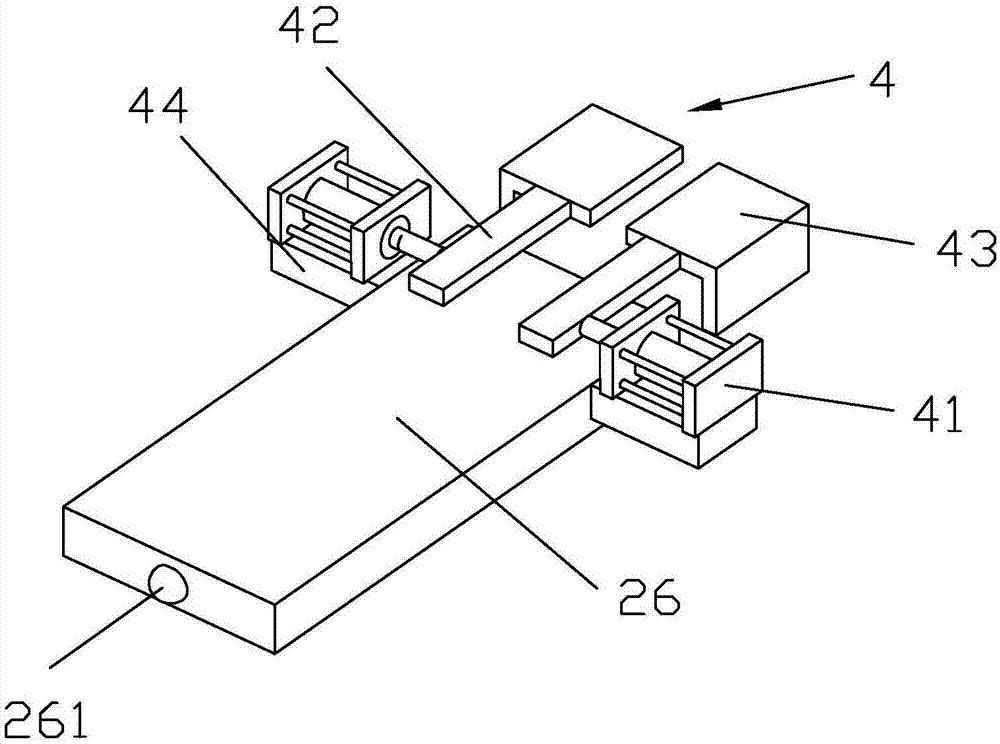

[0022] like Figure 1-4 As shown, it is an automatic conveying device for electronic product detection according to the present invention, which includes a conveying device 1, a moving device 2 and a detecting device 3. Base 11 is positioned at the lower side of conveying platform 12, and side fence 13 is respectively positioned at the left and right sides of conveying platform 12, and the front end of side fence 13 is hinged with front fence 14, and front fence 14 is positioned at the front side of conveying platform 12. The conveying platform 12 is placed at a suitable height and position through the conveying base 11, so as to facilitate the grasping of the electronic products by the mobile device 2; the set side baffle 13 prevents the falling of the electronic products and improves the safety of conveying; the set front The baffle plate 14 is used to prevent the electronic product from moving forward and stop the electronic product from moving, so as to facilitate the gras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com