Method for manufacturing a gearbox for a washing machine

A manufacturing method and gearbox technology, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of damaged cleaning treatment, inability to ensure full welding, and inability to ensure sealing, so as to achieve the effect of ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

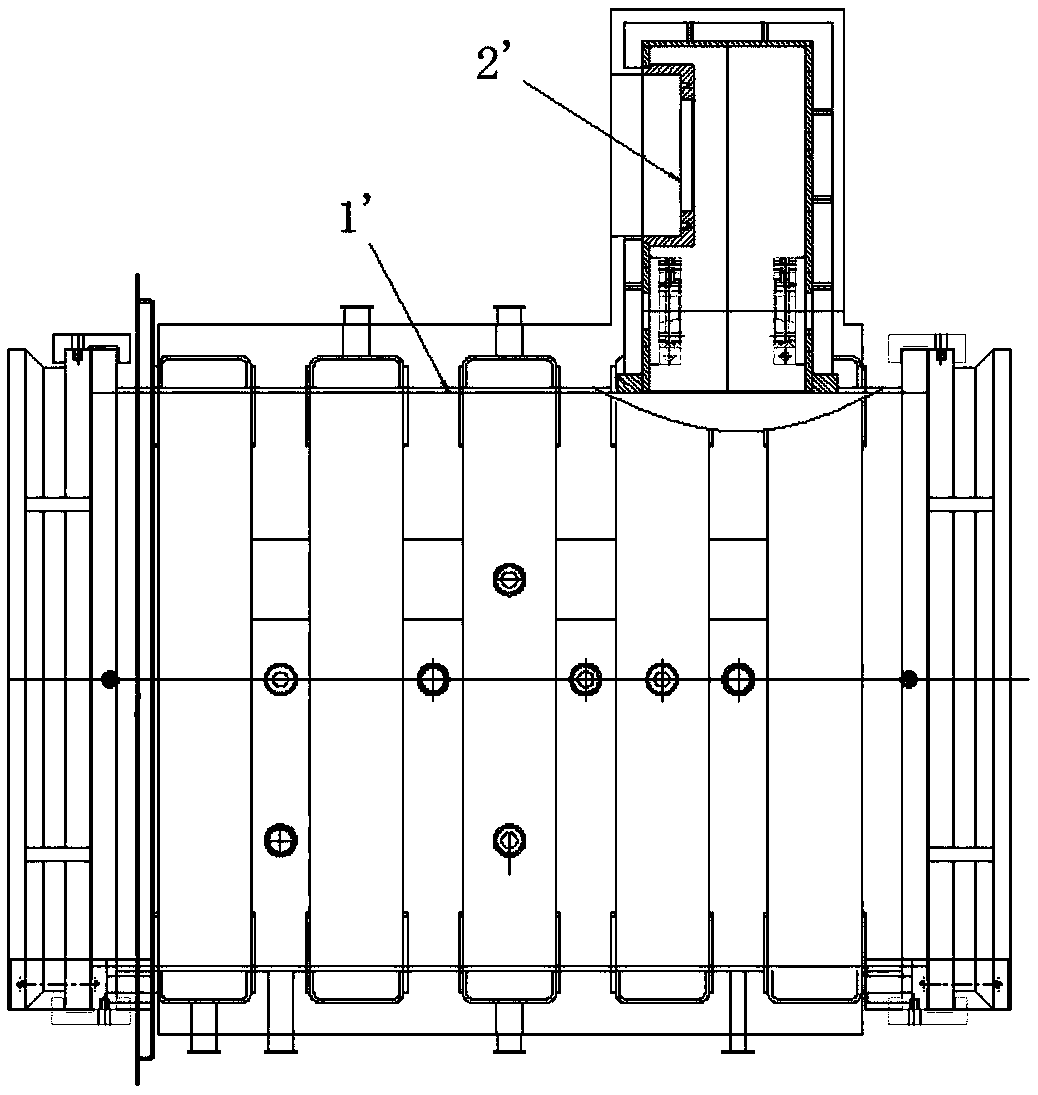

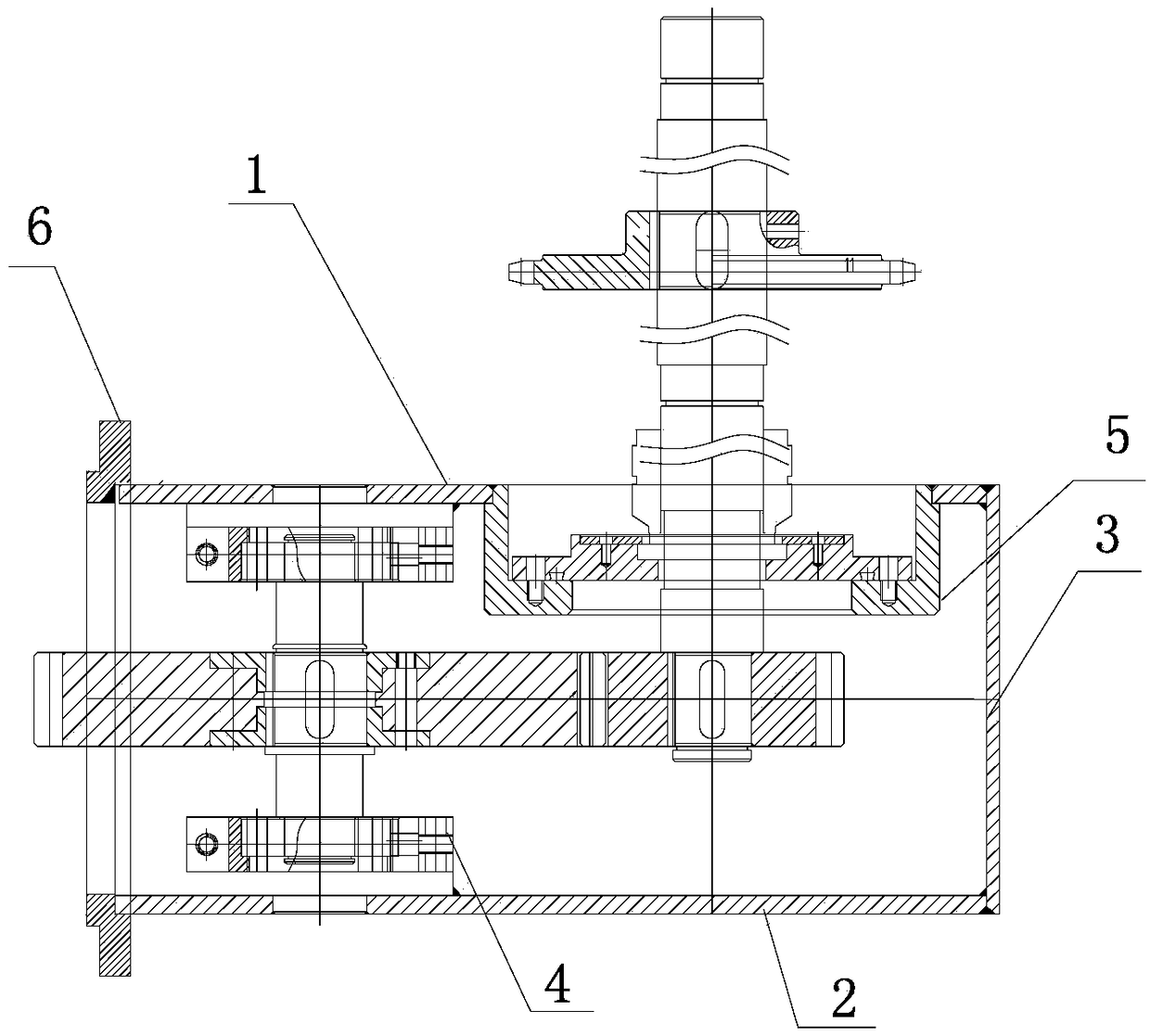

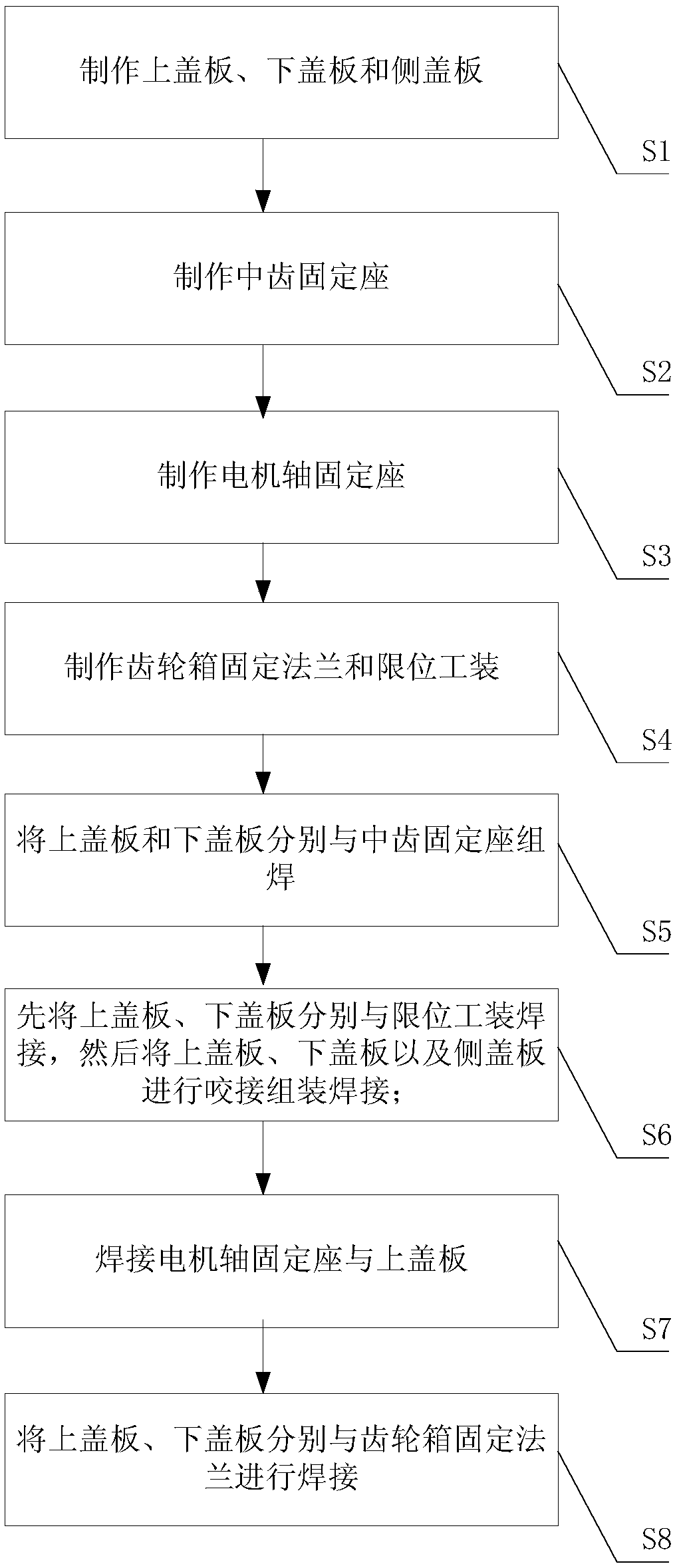

[0042] The specific structure of the gearbox is as follows: figure 2 with Figure 11 , including an upper cover plate 1, a lower cover plate 2, a side cover plate 3, a middle tooth fixing seat 4, a motor shaft fixing seat 5, a gearbox fixing flange 6 and a limit tooling 7. One end of the upper cover plate 1 and the lower cover plate 2 are snap-welded with the upper and lower ends of the side cover plate 3 respectively, and the other ends are respectively welded with the fixed flange 6 of the gearbox. The gear box fixing flange 6 is welded with the cleaning machine housing. The middle tooth fixing seat 4 is fixed between the upper cover plate 1 and the lower cover plate 2 , and the plane where the middle tooth fixing seat 4 is located is parallel to the plane where the upper cover plate 1 is located. The motor shaft fixing seat 5 is fixed on the upper cover plate 1 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com