A parallel vibrating screen for maggot material separation

A vibrating screen and parallel technology, which is applied in the field of multi-dimensional vibrating screening equipment for agricultural biological materials, can solve the problems of low degree of industrialization, uncontrollability, and low efficiency, and achieve improved screening efficiency, overall light weight, and small overall size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

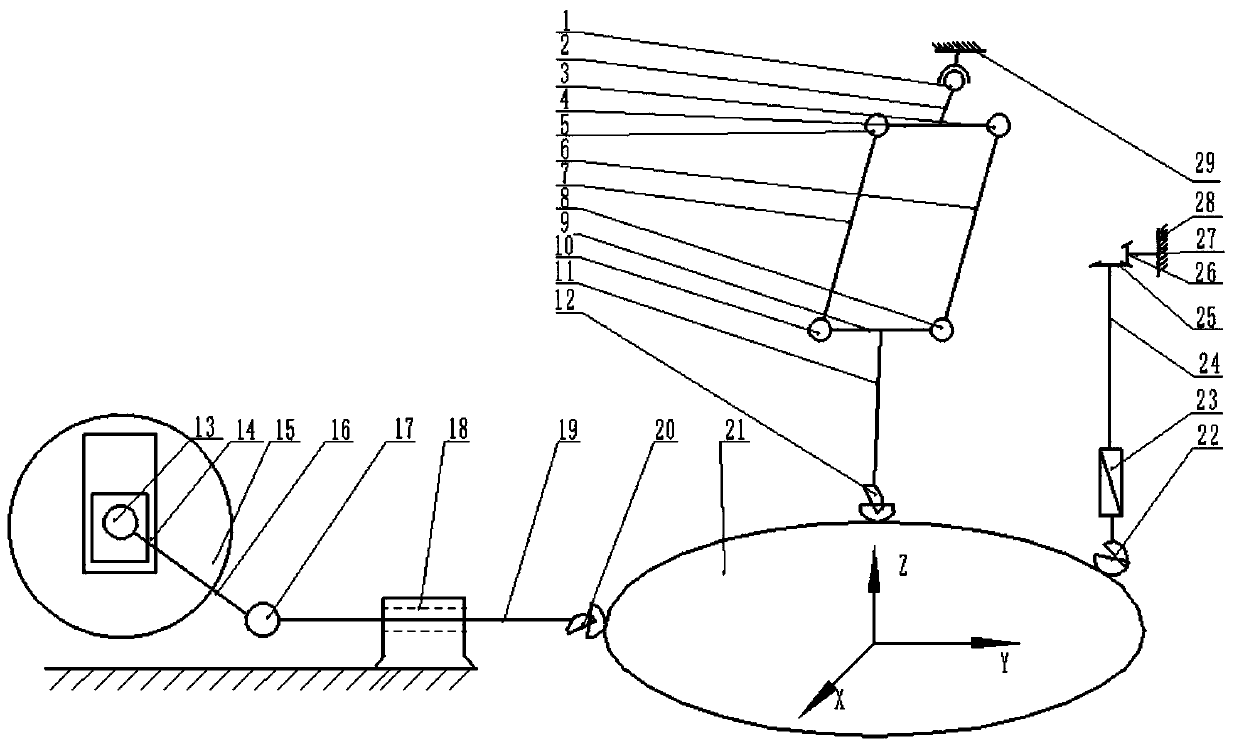

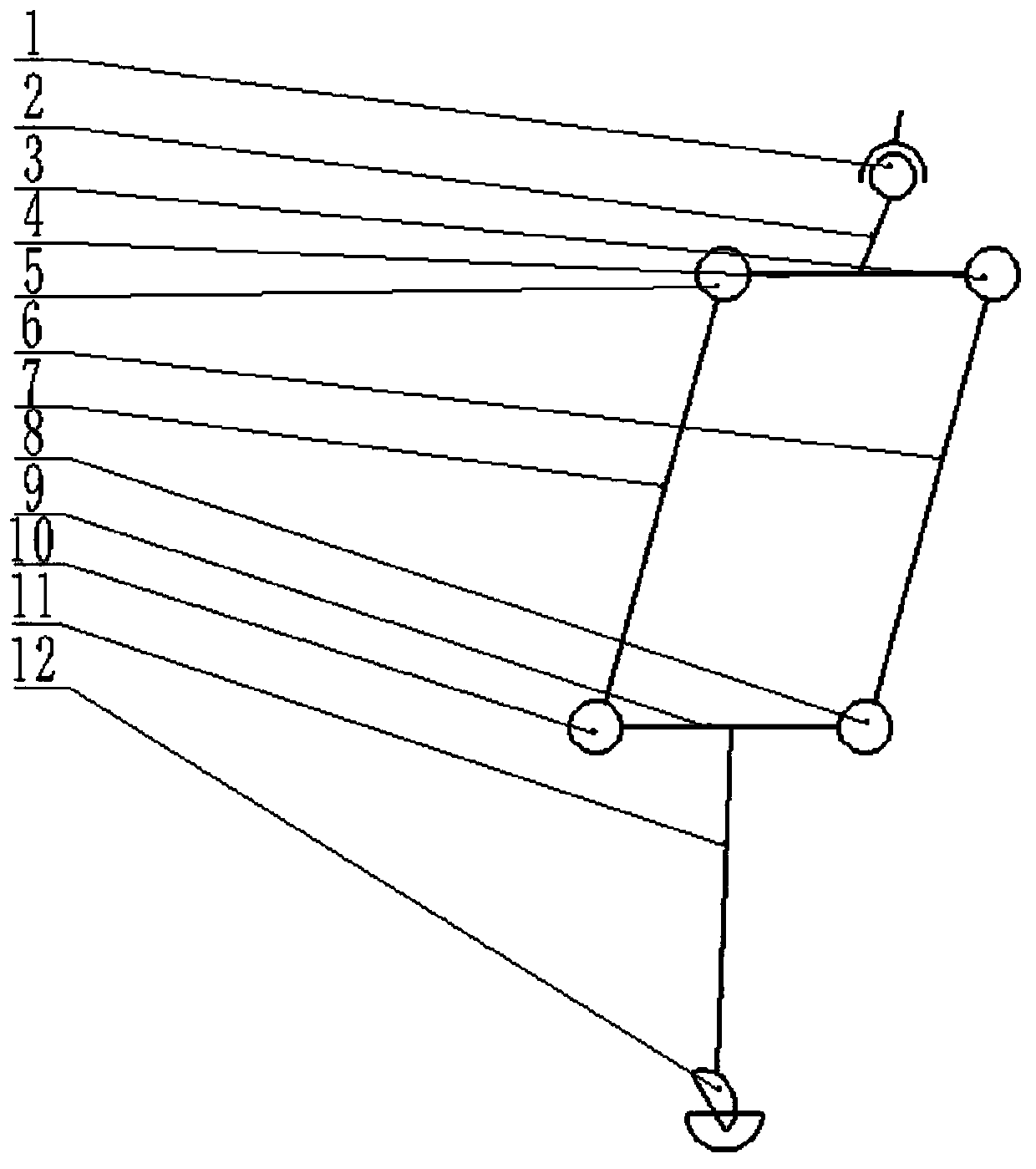

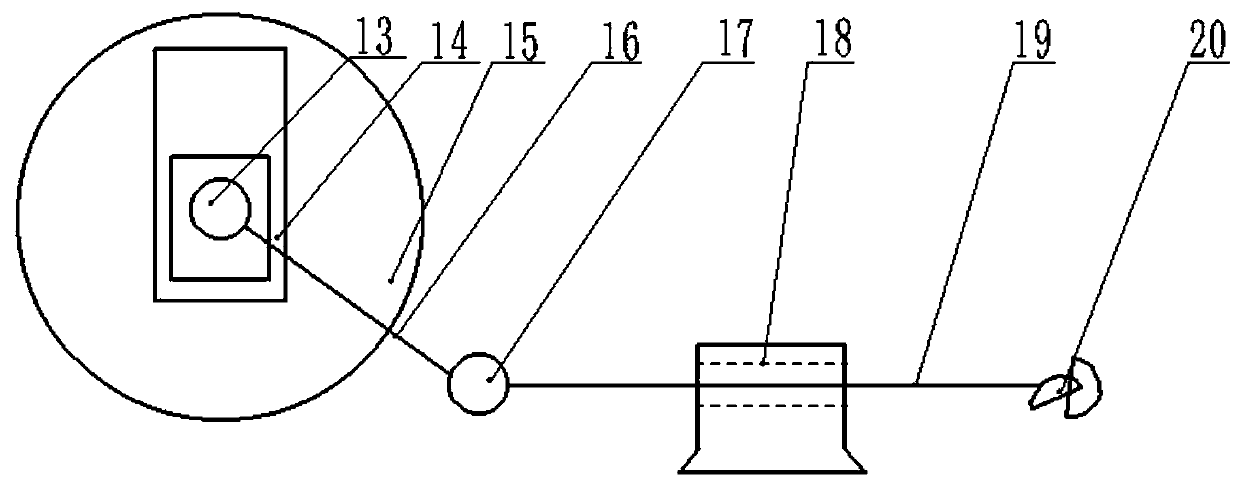

[0025] The technical realization of the present invention is achieved by the following scheme: a parallel vibrating screen for the separation of maggots, which includes a static platform, a first branch chain, a second branch chain, a third branch chain and a screen frame, wherein the screen frame is located at Directly below the static platform; the head end of the first branch chain is connected to the static platform, and the end is connected to the screen frame; the head end of the second branch chain is connected to the power input rotating wheel, and the end is connected to the screen frame; the third branch chain The bevel gear at the head end is connected with the static platform, and the Hooke hinge at the end is connected with the screen frame. During the initial installation, the plane where the static platform is located and the plane where the screen frame is located are parallel to each other.

[0026] The first branch chain includes ball pair 1, Hooke hinge I12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com