Automatic rotating sprayer

An automatic rotating and rotating head technology, applied in the field of atomization, can solve the problems of the heavy weight of the rotating head and the poor atomization effect of the atomizing nozzle, and achieve the effect of reducing the weight, reducing the resistance and increasing the atomization area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

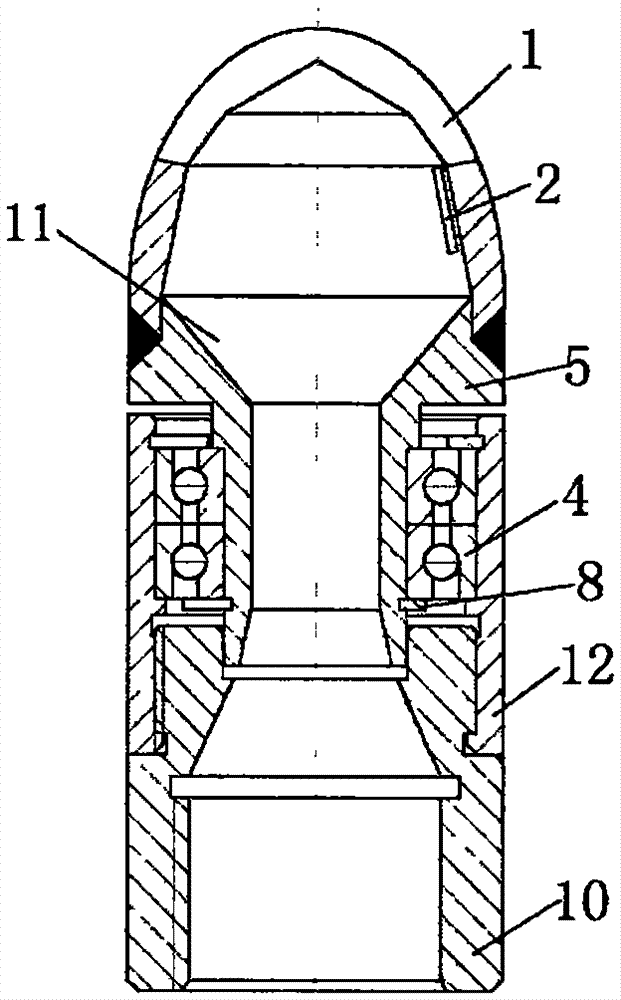

[0056] Such as figure 1 As shown, the embodiment of the present invention provides an automatic rotary spray head, including

[0057] stator;

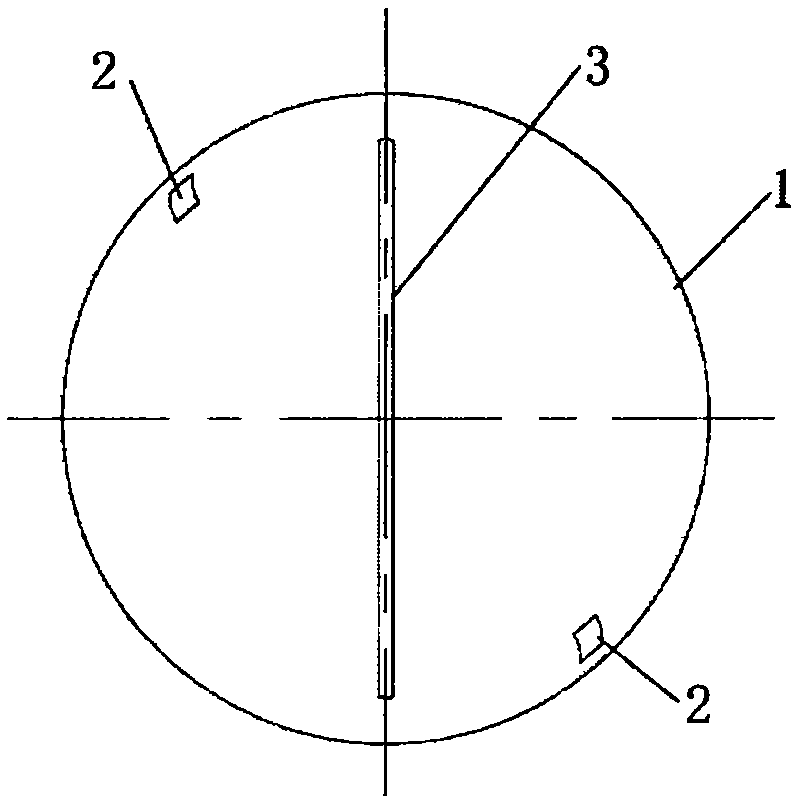

[0058] The rotary head 1 is rotatably connected to the stator, has a fluid chamber, at least one fluid inlet 11 and several fluid outlets communicated with the fluid chamber;

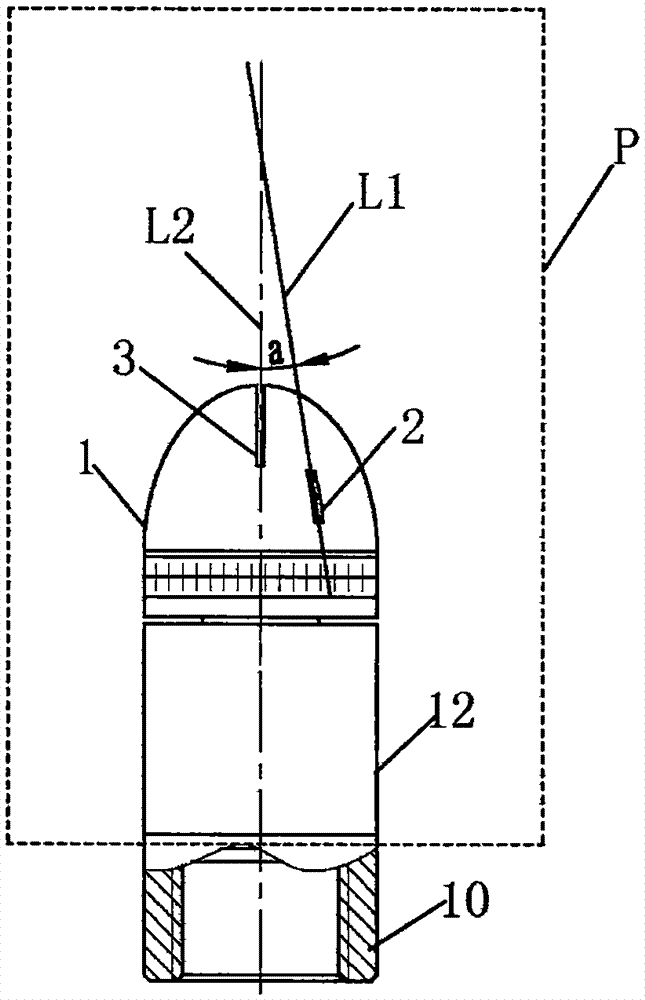

[0059] The power slit 2, at least one, is arranged on the rotating head 1 and communicates with the fluid chamber; the projection line L1 of its axis on the longitudinal projection plane P, and the projection of the axis of the height direction of the rotating head 1 on the longitudinal projection plane P Line L2 does not coincide, as figure 2 shown.

[0060] The above-mentioned automatic rotary spray head only needs to set up a power slit 2 on the rotary head 1, the projection line L1 of the axis of the power slit 2 on the longitudinal projection plane P, and the axis of the height direction of the rotary head 1 on the longitudinal projection plane The pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com