Flooded modular structure flat plate ceramic membrane filtration system

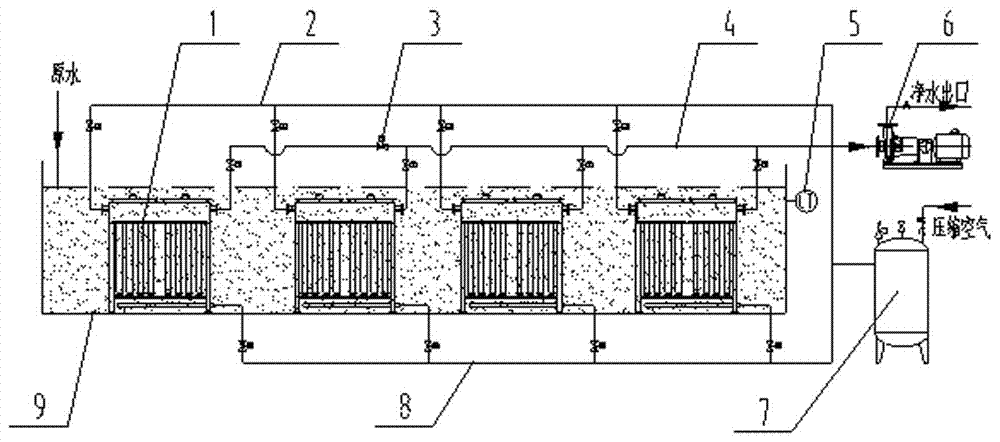

A filtration system and ceramic membrane technology, applied in the field of water treatment, can solve the problems of unsatisfactory anti-cleaning effect, difficult maintenance and large structural resistance, etc., and achieve the effect of convenient and reliable anti-cleaning effect, simple structure and small filtration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

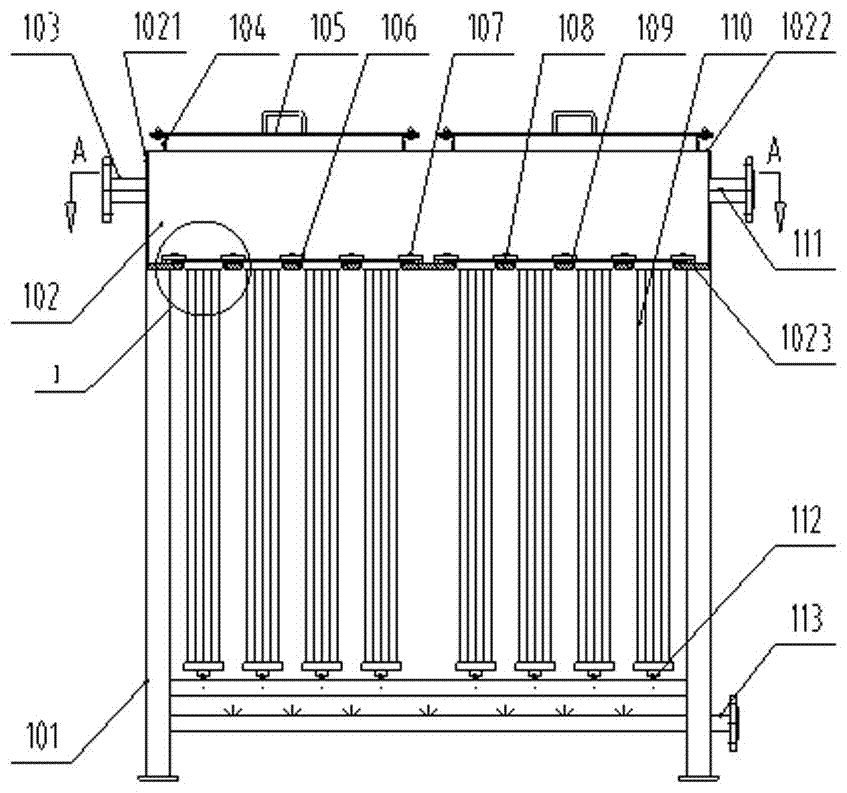

[0033] see Figure 2 to Figure 6 , the above-mentioned flat ceramic membrane filter device 1 is a filter unit, which includes a lower bracket 101 and an upper water collection chamber 102 . The water collection chamber 102 includes an orifice 1023 at the bottom, a surrounding plate 1021, and a top plate 1022 on the top. An inspection hole is opened on the top plate 1022, and the inspection hole flange 104 is fixed. The inspection hole flange 104 is provided with an open inspection hole cover 105 , so as to form a relatively closed space. The water collection chamber 102 is fixedly supported on the bracket 101, and the water collection chamber 102 is provided with a clean water outlet 111 and a reverse cleaning air inlet 103 on the outside of the coaming, and is respectively connected to the clean water main pipe 4 and the backwash through the respective branch valves 3. On the cleaning main pipe 2, the clean water main pipe 4 and the backwash main pipe 2 are respectively conn...

Embodiment 2

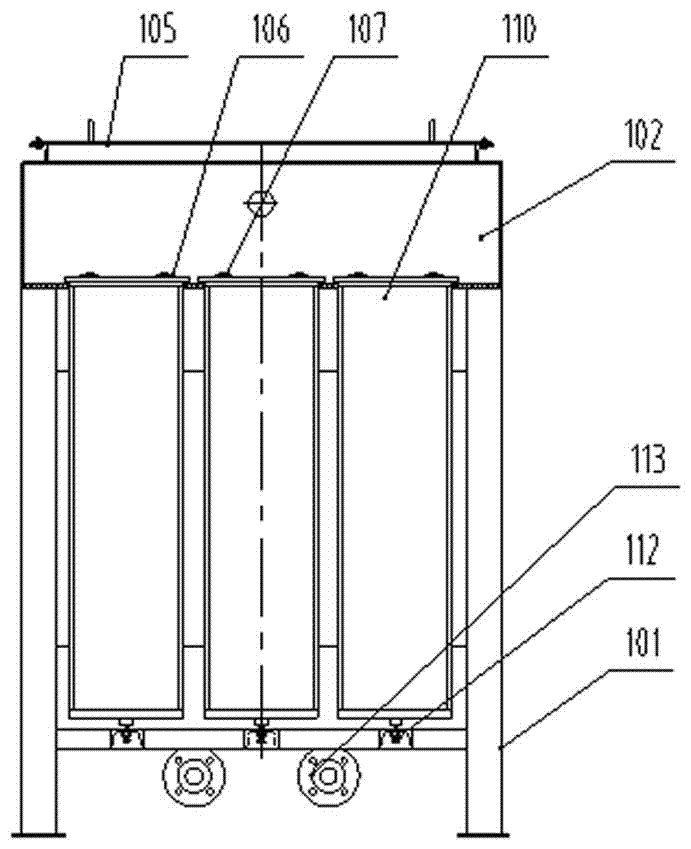

[0037] see Figure 7 to Figure 11 , the structure of this embodiment is basically the same as that of Embodiment 1, except that the structure of the upper connecting piece 1101 and the orifice plate 1023 of the flat ceramic membrane module 110 are different, as shown in Figure 9, Figure 10 , Figure 11 shown. In this embodiment, the upper connector 1101 of the flat ceramic membrane module 110 is a threaded structure, and the orifice 1023 at the bottom of the water collection chamber 102 is a plate-shaped member. The circular holes with the same number of series, the size and shape of the holes correspond to the size and shape of the threaded structure of the upper connecting piece 1101 . The upper connecting piece 1101 of the flat ceramic membrane module 110 is inserted into the circular hole on the orifice plate 1023 through the bottom of the bracket 101 from the bottom of the orifice plate 1023. Screw on the large nut 115 on the cylindrical platform, and place the gasket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com