Potato whole starch preparation method

A raw potato powder and potato technology, which is applied in ultra-high pressure food processing, food drying, food science, etc., can solve problems such as food safety hazards, oxidation, browning, and taste effects of raw potato powder, and achieve heat-sensitive nutrients. Small damage, excellent processability, prevent color deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

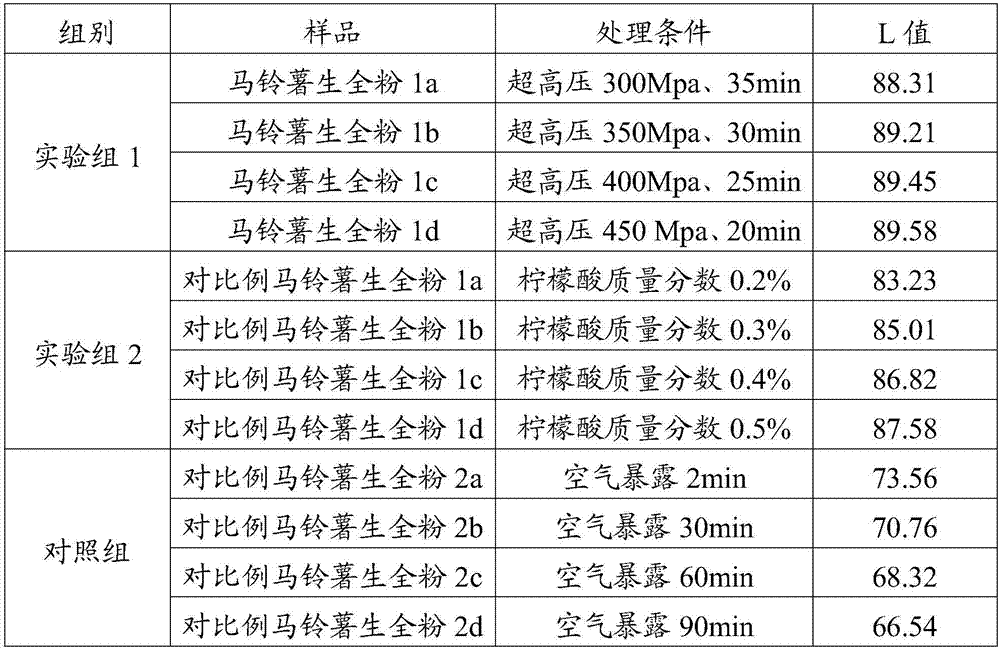

[0025] The invention provides a method for preparing raw potato powder, wherein no color-protecting agent is added in the preparation process, which specifically includes the following steps:

[0026] (1) Make the volume not greater than 5cm 3 The potato pieces are vacuum-packed, and the vacuum degree in the package is -0.2~-0.05MPa;

[0027] (2) placing the vacuum-packed potato pieces obtained in the step (1) under ultra-high pressure conditions for 20-60 minutes;

[0028] (3) Freeze the potato pieces processed under the ultra-high pressure condition in the step (2) to the drying temperature and carry out vacuum freeze-drying to obtain dehydrated potatoes. The conditions of the vacuum freeze-drying: the absolute atmospheric pressure is 12~40Pa, and the temperature is - 55~-40°C, the water content of the dehydrated potatoes is lower than 10wt%;

[0029] (4) Grinding the dehydrated potatoes obtained in the step (3) to 90-150 mesh to obtain raw potato powder.

[0030] The col...

Embodiment 1

[0044] Using Yu Potato No. 1 as raw material, select potato tubers with few buds, no rot and no pests; clean the potatoes with a potato cleaning machine, and the temperature of the cleaning water is between 15 and 25°C. After washing, rot, germination and green Peeled potatoes are picked out. The cleaned potatoes are removed with a potato peeler, and the peeled potatoes are cut into potato pieces of 1 cm * 1 cm * 5 mm with a potato slicer.

[0045] Put the potato pieces into a vacuum packaging bag for vacuuming, so that the vacuum degree in the vacuum bag packed with potato pieces is -0.18±0.02MPa; at room temperature, place the vacuum-packed potato pieces under 300Mpa ultra-high pressure conditions for 35min .

[0046] Unpack the potato pieces treated under ultra-high pressure and put them into a freeze-drying bottle for 1.5 hours to freeze to -40°C, and then put them into the vacuum chamber of a freeze dryer for vacuum freeze-drying and dehydration. The freeze-drying temper...

Embodiment 2

[0057] Using Luo Potato No. 8 as the raw material, select potato tubers with few buds, no rot and no pests; clean the potatoes with a potato cleaning machine, and the temperature of the cleaning water is between 15 and 25°C. After cleaning, rot, germination and green Peeled potatoes are picked out. The cleaned potatoes are removed with a potato peeler, and the peeled potatoes are mechanically cut into potato pieces of 1 cm × 1 cm × 5 cm.

[0058] Put the potato pieces into a vacuum packaging bag for vacuuming, so that the vacuum degree in the vacuum bag packed with potato pieces is -0.07±0.02MPa; at room temperature, place the vacuum-packed potato pieces under an ultra-high pressure of 350Mpa for 30min .

[0059] Unpack the potato pieces treated under ultra-high pressure and put them into a freeze-drying bottle for 2 hours to freeze to -48°C, then put them into the vacuum chamber of a freeze dryer for vacuum freeze-drying and dehydration, the freeze-drying temperature is -48°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com