Method for detecting thickness and surface topography of respective layer inside lithium ion battery

A lithium-ion battery and surface topography technology, applied in measuring devices, instruments, using ultrasonic/sonic/infrasonic waves, etc., can solve the problems of low resolution, damage to samples, fast attenuation, etc., to achieve simple operation and low equipment investment , Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

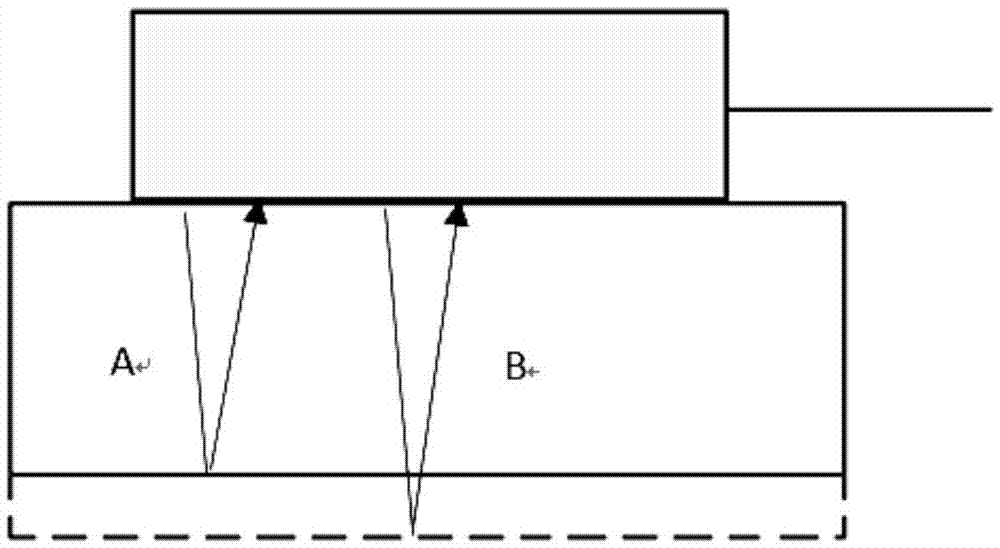

[0046] Use the steel sheet as the substrate, use the ultrasonic probe with a frequency of 10MHz as the ultrasonic pulse transmitter, take a certain amount of coupling agent and apply it on the contact surface between the steel sheet and the ultrasonic generating / receiving probe, make close contact, turn on the oscilloscope and pulse generator, and adjust the ultrasonic frequency The test is carried out until it matches the thickness of the sample, and the test result is analyzed to obtain the periodic signal of the thickness of the steel sheet. Such as figure 2 shown.

Embodiment 2

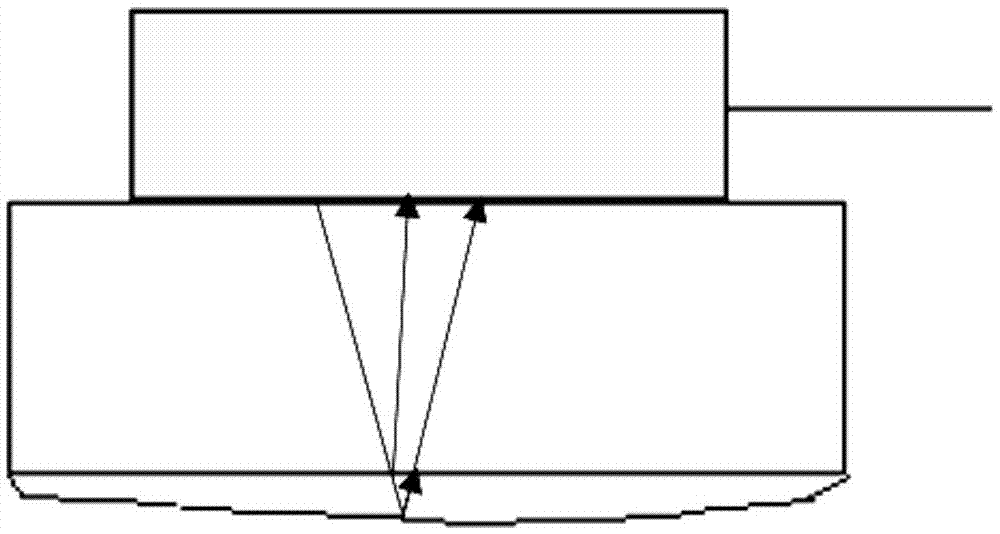

[0048]Use aluminum foil as the substrate, use the ultrasonic probe with a frequency of 10MHz as the ultrasonic pulse transmitter, take a certain amount of couplant and apply it on the contact surface between the aluminum foil and the ultrasonic generating / receiving probe, and make close contact, turn on the oscilloscope and pulse generator, and adjust the ultrasonic frequency to match The thickness of the sample is consistent, the test is carried out, and the test result is analyzed to obtain the periodic signal of the thickness of the aluminum foil.

Embodiment 3

[0050] Use the positive shell as the substrate, and use the ultrasonic probe with a frequency of 10MHz as the ultrasonic pulse transmitter. Take a certain amount of couplant and apply it on the contact surface between the positive shell and the ultrasonic generating / receiving probe, make close contact, turn on the oscilloscope and pulse generator, and adjust the ultrasonic frequency. The test is carried out until it matches the thickness of the sample, and the test result is analyzed to obtain a periodic signal of the thickness of the positive electrode shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com