Dyeing technology

A process and primary color technology, applied in the field of dyeing process, can solve problems such as waste of resources, land and facilities, damage to the environment, and adverse effects of environmental protection, and achieve the effects of reducing resource waste and environmental pollution, improving economic benefits, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

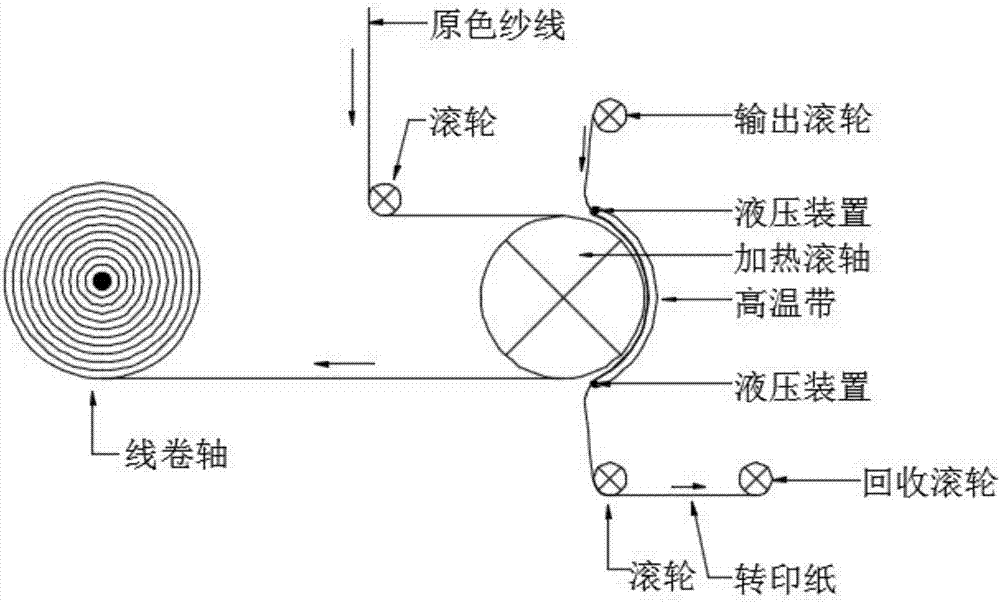

[0014] see figure 1 , a dyeing process, the concrete steps are as follows:

[0015] Step 1, install the primary color yarn and transfer paper according to the procedure, start the machine, and all components are controlled by computer;

[0016] Step 2, the roller and the roller rotate synchronously, and the hydraulic devices at both ends of the high temperature belt bend the high temperature belt and the transfer paper towards the heating roller and keep a certain distance;

[0017] Step 3: The high-temperature belt and the heating roller heat the transfer paper and the original color yarn, the ink on the transfer paper is sublimated by heat and adheres to the original color yarn, and the dyed yarn is recovered by the thread reel, and output during this process The roller outputs new transfer paper and the return roller recycles old sublimated tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com