Preparation method and preparation apparatus of high-grade 4-tert-butylbenzaldehyde

A technology of p-tert-butyltoluene and p-tert-butyl, applied in the chemical field, can solve the problems of limited gas-liquid contact area, tail gas emission pollution, low oxygen utilization rate, etc., achieve short reaction time, large gas-liquid contact area, The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

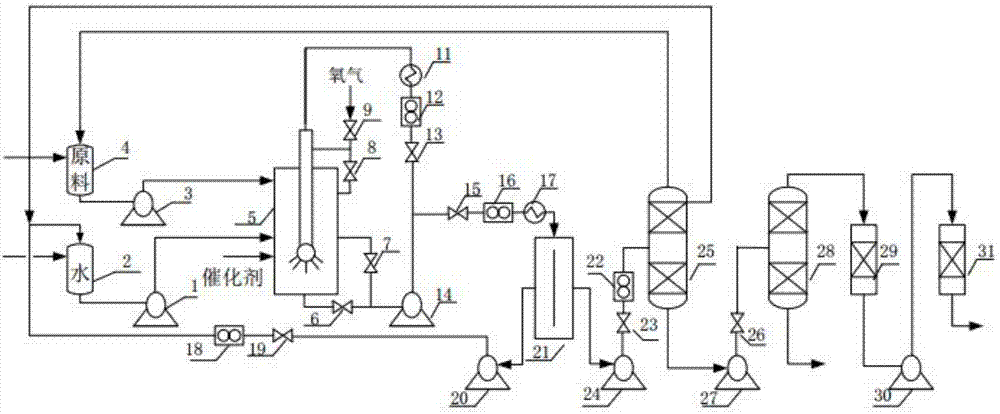

[0027] The invention provides a method for preparing high-grade p-tert-butylbenzaldehyde. The preparation method of high-grade p-tert-butylbenzaldehyde according to the embodiment of the present invention comprises the following steps:

[0028] A) Mix p-tert-butyltoluene, water and a halogen-free catalyst in a micro-bubble reactor and perform an oxidation reaction to obtain a reaction feed liquid;

[0029] B) oil-water separation is carried out to the reaction feed liquid, so as to obtain a water phase and an oil phase, the water phase contains a catalyst, and the oil phase contains p-tert-butylbenzaldehyde and impurities; and

[0030] C) Separating the p-tert-butylbenzaldehyde and the impurity to obtain high-grade p-tert-butylbenzaldehyde.

[0031] Since the high-grade p-tert-butylbenzaldehyde preparation method according to the embodiment of the present invention uses a halogen-free catalyst, the p-tert-butylbenzene prepared according to the high-grade p-tert-butylbenzaldeh...

Embodiment 1

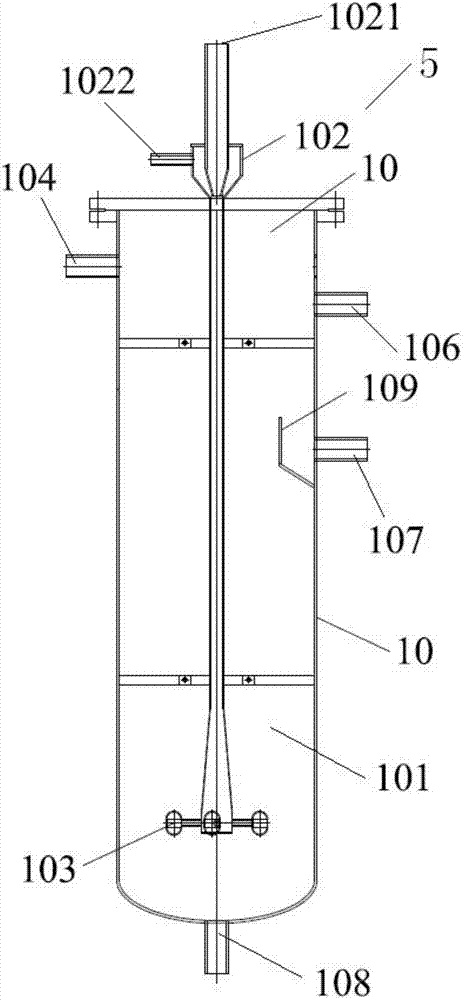

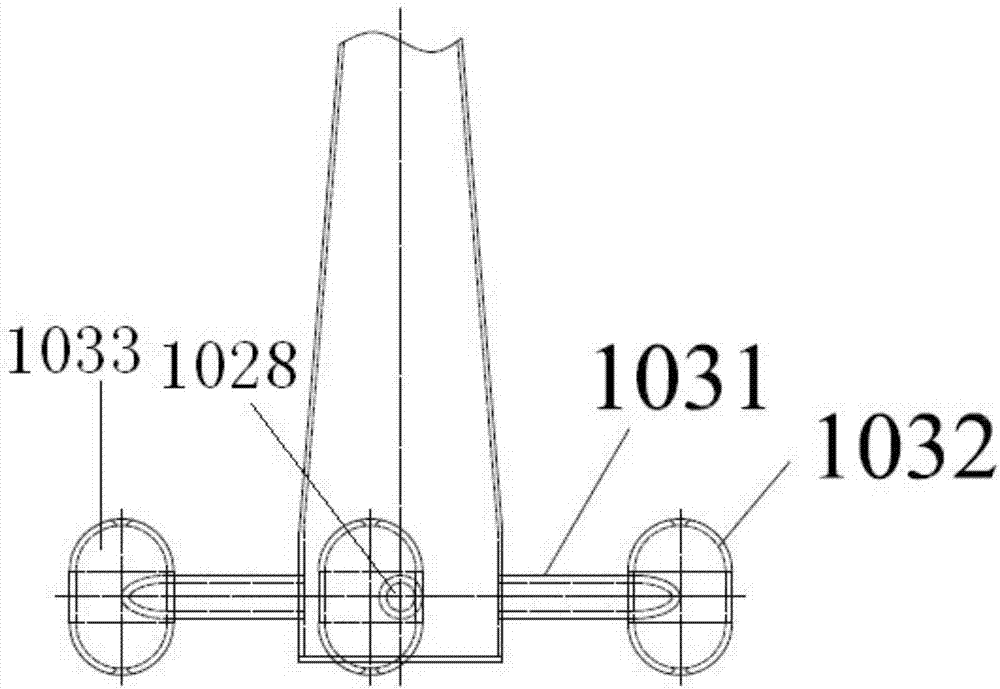

[0071] The catalyst is dissolved in solvent water with a mass fraction of 1%, and p-tert-butyltoluene and solvent water are transported to the 100L microbubble reactor 5 by pump 3 and pump 1 according to the mass ratio of 1:1. When adding the feed liquid of 60 kg, that is, when the total weight of p-tert-butyltoluene, water and catalyst is 60 kg, stop feeding, open the pump 14, and make the flow rate of the feed liquid of circulation be 1000L / h, micron bubble reactor 5. The size of the generated bubbles is 500nm-500μm. The circulating feed liquid is heated through the heat exchanger 11. When the temperature rises to 50°C, oxygen is introduced into the micro-bubble reactor 5 to increase the pressure in the micro-bubble reactor 5. to 0.2MPa (gauge pressure).

[0072] After 1.6 hours of reaction, open the valve 15, pump 1 and pump 3, adjust the flow meter 16, and send the reaction material liquid to the phase separator 21 at a flow rate of 10L / h, so that the pump 1 and pump 3 rea...

Embodiment 2

[0076] The catalyst is dissolved in solvent water with a mass fraction of 1.2%, and p-tert-butyltoluene and solvent water are transported to the 100L microbubble reactor 5 by pump 3 and pump 1 according to the mass ratio of 1:1.5. When adding the feed liquid of 60kg, that is, when the total weight of p-tert-butyltoluene, water and catalyzer is 60 kg, stop feeding, open pump 14, make the flow of the feed liquid of circulation be 20000L / h, micron bubble reactor 5 The size of the generated bubbles is 50 μm-1000 μm, and the circulating feed liquid is heated through the heat exchanger 11. When the temperature rises to 90°C, oxygen is introduced into the micro-bubble reactor 5 to reduce the pressure in the micro-bubble reactor 5. Rise to 0.3MPa (gauge pressure).

[0077] After reacting for 0.1 hour, open the valve 15, pump 1 and pump 3, adjust the flow meter 16, and deliver the reaction material liquid to the phase separator 21 at a flow rate of 100L / h, so that the pump 1 and pump 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com