Honeycombed catalyst material and forming method thereof

A honeycomb catalyst and catalyst technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of powder materials falling off easily, affecting the reaction, and large wind resistance, etc., to achieve the best catalytic performance, Unified structure and low wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A honeycomb catalyst material comprising the following components:

[0054] Manganese dioxide 108g;

[0056] Activated carbon 40g;

[0057] Kaolin powder 40g;

[0058] The catalyst molding process includes the following steps:

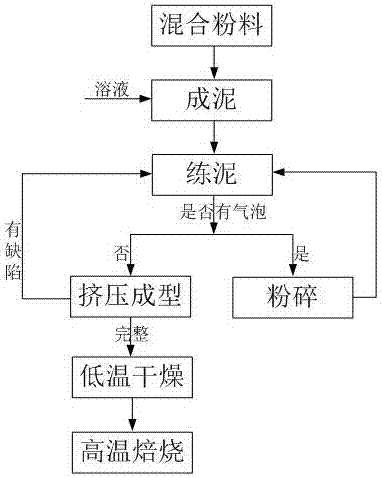

[0059] 1. Weigh 108g of manganese dioxide, 12g of copper oxide, 40g of activated carbon and 40g of kaolin powder, mix the above-mentioned powders evenly, and add 160g of water to the mixed powder to form a paste material for later use;

[0060] 2. Transfer the above-mentioned pasty wet material to the mud refining device for exhaust-crushing-exhaust-crushing-exhaust treatment to obtain paste material without air bubbles for use;

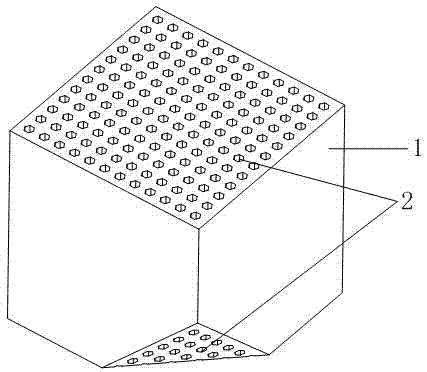

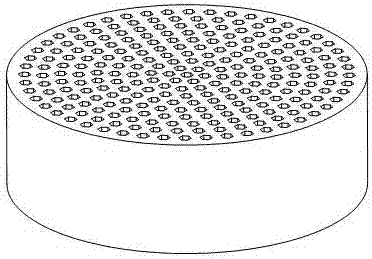

[0061] 3. Transfer the above-mentioned materials processed by the mud refining device to the extrusion molding equipment, and use a square mold with a size of 200*200*100mm with a honeycomb porous structure inside for extrusion molding to obtain a honeycomb with an internal aperture of 1mm ...

Embodiment 2

[0066] Honeycomb catalyst material, comprising the following components:

[0067] Manganese dioxide 100g;

[0068] Iron oxide 10g;

[0069] Molecular sieve 50g;

[0070] Kaolin powder 40g;

[0071] The catalyst molding process includes the following steps:

[0072] 1. Weigh 100g of manganese dioxide, 10g of iron oxide, 50g of molecular sieve and 40g of kaolin powder respectively, mix the above powders evenly, and add 180g of water to the mixed powder to mix into a paste material for later use;

[0073] 2. Transfer the above-mentioned pasty wet material to the mud refining device for exhaust-crushing-exhaust-crushing-exhaust treatment to obtain paste material without air bubbles for use;

[0074] 3. Transfer the above-mentioned materials processed by the mud refining device to extrusion molding equipment, and use a square mold with a size of 200*200*100mm with a honeycomb porous structure inside for extrusion molding to obtain a honeycomb with an internal aperture of 2mm C...

Embodiment 3

[0079] Honeycomb catalyst material, comprising the following components:

[0080] Manganese dioxide 90g;

[0081] Copper oxide 10g, iron oxide 5g;

[0082] Diatomaceous earth 60g;

[0083] Carboxymethylcellulose powder 3.5g;

[0084] The catalyst molding process includes the following steps:

[0085] 1. Weigh 90g of manganese dioxide, 10g of copper oxide, 5g of iron oxide, 60g of diatomaceous earth and 3.5g of carboxymethyl cellulose powder, mix the above powders evenly, and add 100g of water to the mixed powder to mix into a paste material for use;

[0086] 2. Transfer the above-mentioned pasty wet material to the mud refining device for exhaust-crushing-exhaust-crushing-exhaust treatment to obtain paste material without air bubbles for use;

[0087] 3. Transfer the above-mentioned materials processed by the mud refining device to the extrusion molding equipment, and use a square mold with a size of 200*200*100mm with a honeycomb porous structure inside for extrusion mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com