Mixing device for spraying plastic UV light oil on notebook computer

A technology of notebook computer and stirring equipment, which is applied in the directions of mixers, dissolvers, and mixers with rotating stirring devices, can solve the problems of low work efficiency, long time consumption, poor stirring effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

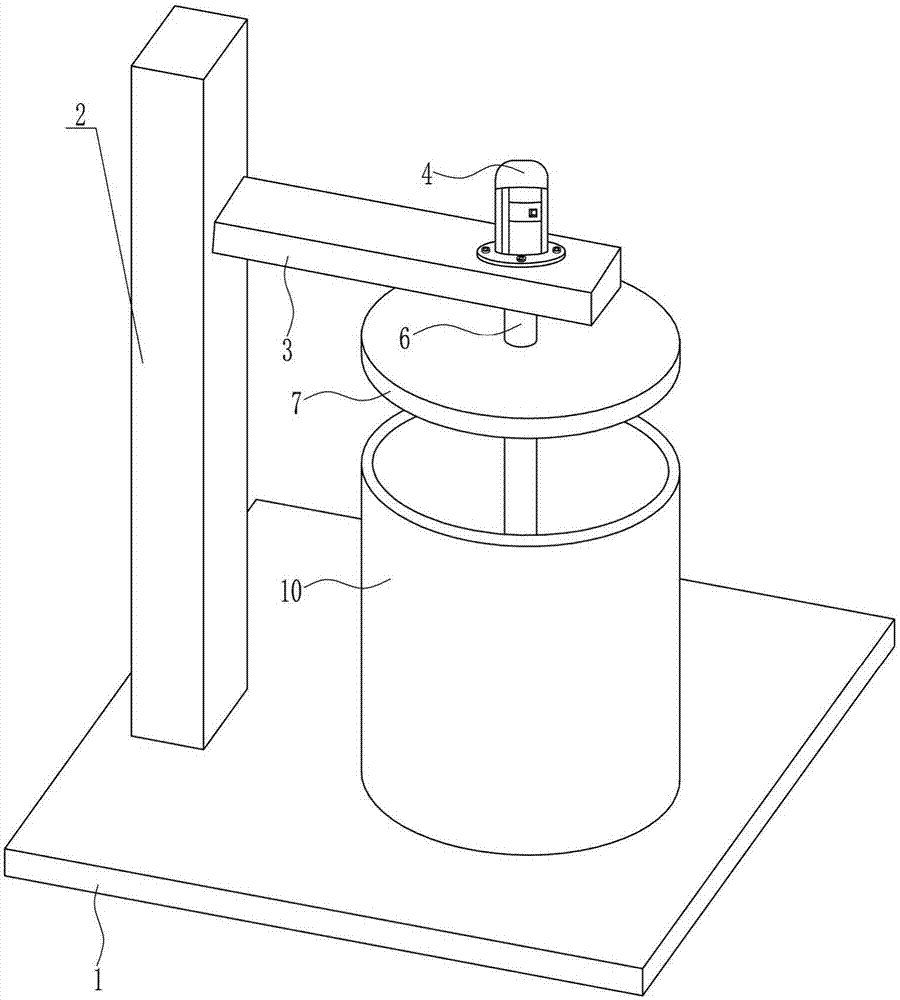

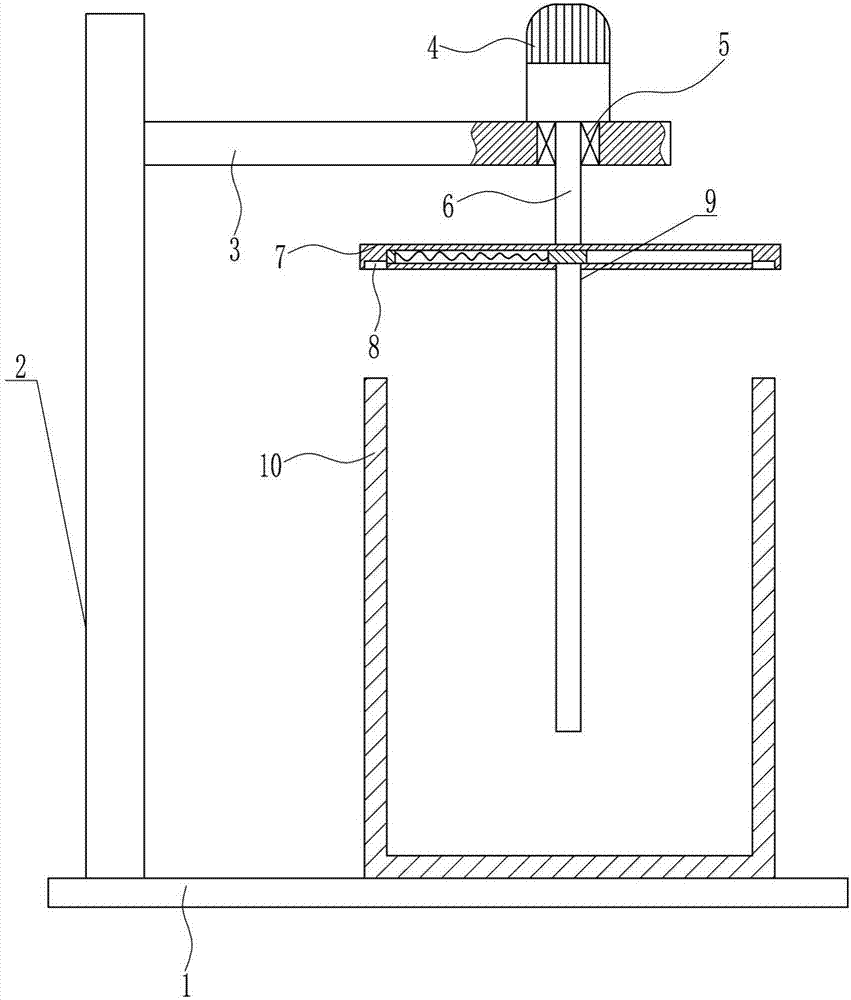

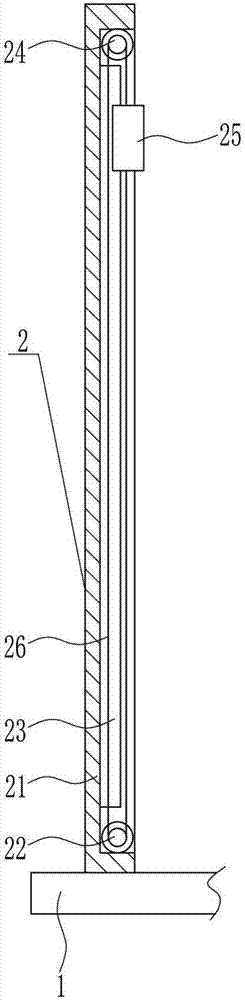

[0041] A stirring device for spraying plastic UV varnish on laptop computers, such as Figure 1-12 As shown, it includes a bottom plate 1, a lifting device 2, a movable plate 3, a first motor 4, a bearing seat 5, a rotating shaft 6, a cover plate 7, a stirring device 9 and a mixing bucket 10, and a lifting device 2 is provided on the left side of the top of the bottom plate 1. , the mobile part of the lifting device 2 is connected with a movable plate 3, and the right side of the movable plate 3 is embedded with a bearing seat 5, and the bearing in the bearing seat 5 is vertically provided with a rotating shaft 6, and the rotating shaft 6 and the bearing in the bearing seat 5 For interference connection, the first motor 4 is installed on the right side of the top of the movable plate 3 through bolt connection, the output shaft of the first motor 4 is connected with the top of the rotating shaft 6 through a coupling, and the lower part of the rotating shaft 6 is connected with a...

Embodiment 2

[0043] A stirring device for spraying plastic UV varnish on laptop computers, such as Figure 1-12 As shown, it includes a bottom plate 1, a lifting device 2, a movable plate 3, a first motor 4, a bearing seat 5, a rotating shaft 6, a cover plate 7, a stirring device 9 and a mixing bucket 10, and a lifting device 2 is provided on the left side of the top of the bottom plate 1. , the mobile part of the lifting device 2 is connected with a movable plate 3, and the right side of the movable plate 3 is embedded with a bearing seat 5, and the bearing in the bearing seat 5 is vertically provided with a rotating shaft 6, and the rotating shaft 6 and the bearing in the bearing seat 5 For interference connection, the first motor 4 is installed on the right side of the top of the movable plate 3 through bolt connection, the output shaft of the first motor 4 is connected with the top of the rotating shaft 6 through a coupling, and the lower part of the rotating shaft 6 is connected with a...

Embodiment 3

[0046] A stirring device for spraying plastic UV varnish on laptop computers, such as Figure 1-12 As shown, it includes a bottom plate 1, a lifting device 2, a movable plate 3, a first motor 4, a bearing seat 5, a rotating shaft 6, a cover plate 7, a stirring device 9 and a mixing bucket 10, and a lifting device 2 is provided on the left side of the top of the bottom plate 1. , the mobile part of the lifting device 2 is connected with a movable plate 3, and the right side of the movable plate 3 is embedded with a bearing seat 5, and the bearing in the bearing seat 5 is vertically provided with a rotating shaft 6, and the rotating shaft 6 and the bearing in the bearing seat 5 For interference connection, the first motor 4 is installed on the right side of the top of the movable plate 3 through bolt connection, the output shaft of the first motor 4 is connected with the top of the rotating shaft 6 through a coupling, and the lower part of the rotating shaft 6 is connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com