Wound battery with continuous tabs, asymmetric composite mesh electrodes and double-membrane safety valves

A composite mesh and safety valve technology, applied in the field of lead-acid batteries and wound lead-acid super batteries, can solve the problems of low grid material strength, low current conduction capacity, uneven current distribution, etc., and achieve heat dissipation performance. Good, improved mechanical strength and anti-vibration performance, improved electrical conductivity and the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

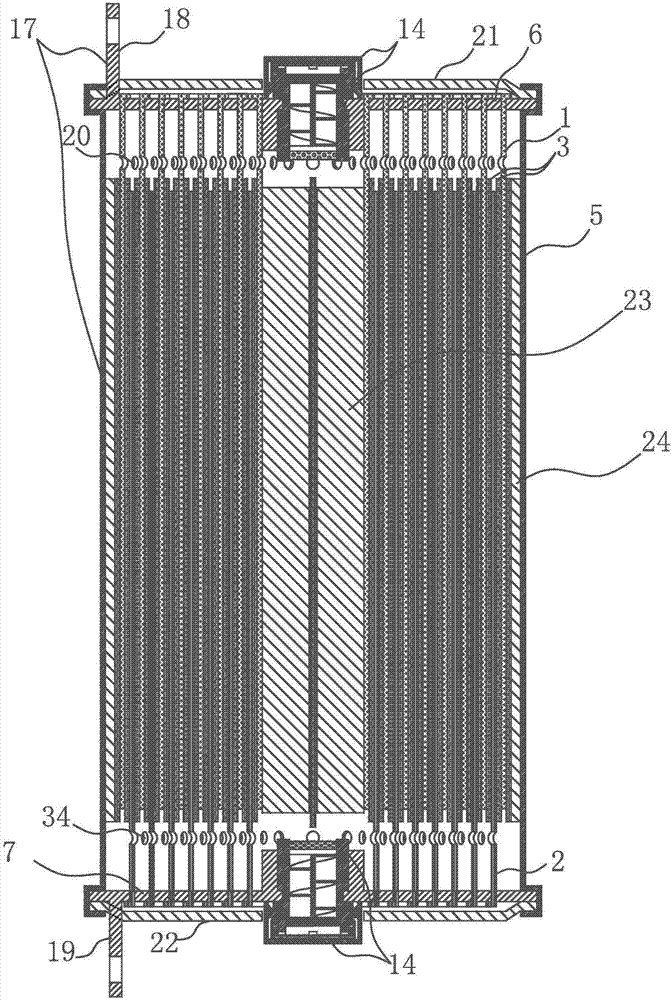

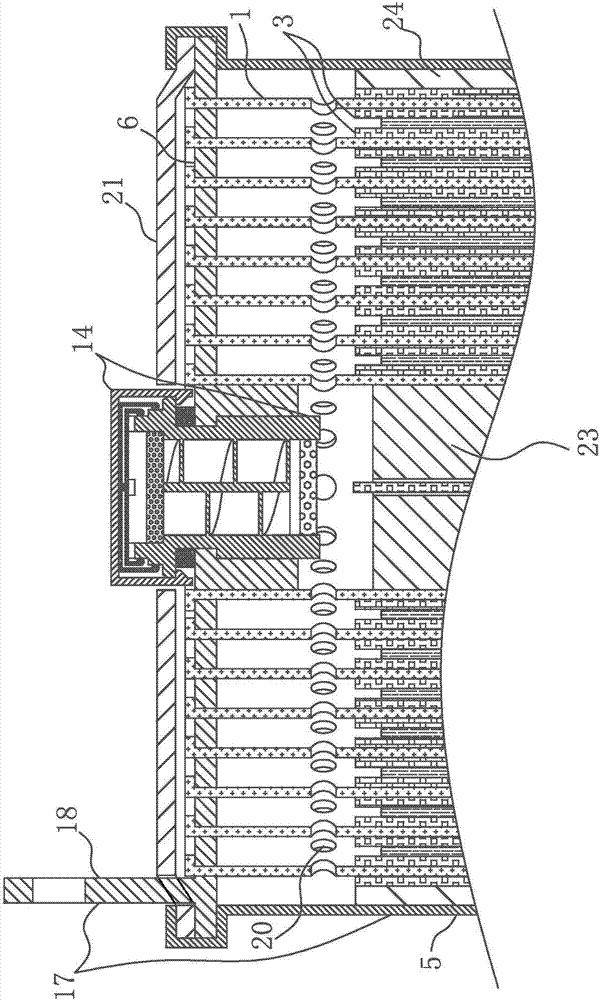

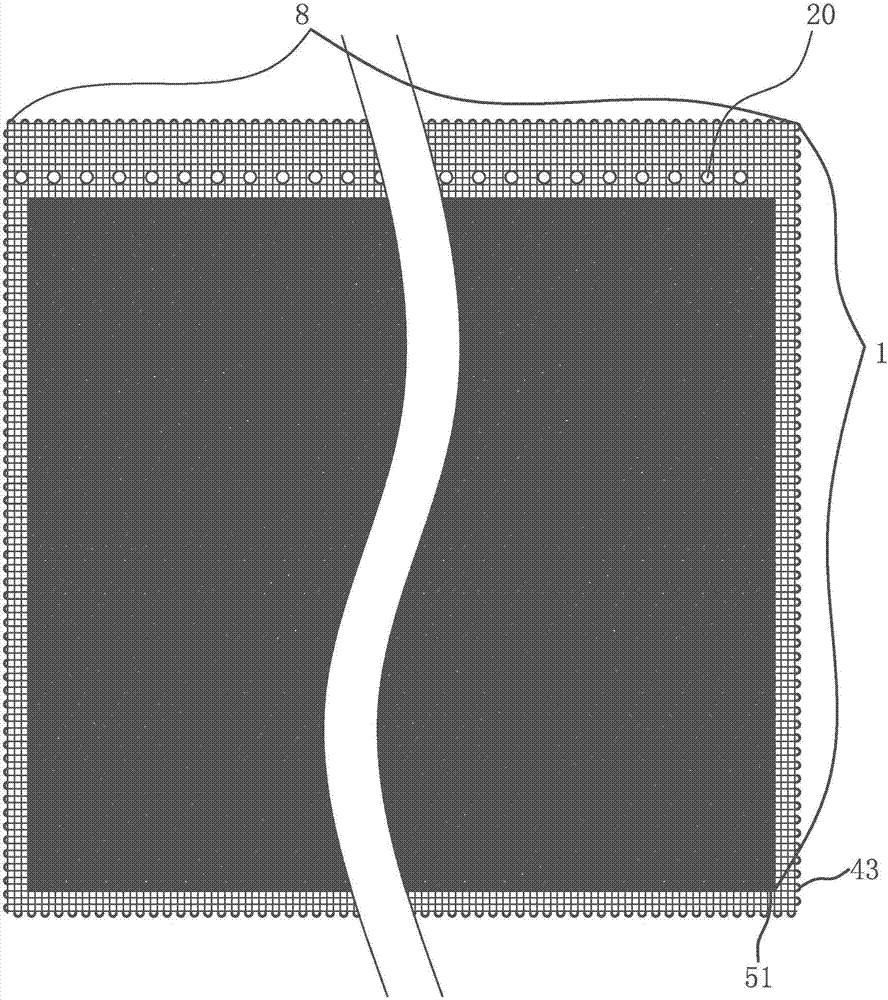

[0028] Such as Figure 1-16As shown, a continuous lug asymmetric composite mesh electrode double-film safety valve winding battery includes a battery case (5) and a battery cell (33), and is characterized in that: the battery cell (33) is composed of a positive electrode sheet (1) , the negative electrode sheet (2) and the diaphragm (3) between the positive electrode sheet and the negative electrode sheet are wound into a columnar body by the battery core reel (23), and the positive electrodes are respectively arranged on the two ends of the battery core (33) Current collector plate (6) and negative electrode current collector plate (7); said positive electrode sheet (1) is provided with a pole ear equal to the length of positive electrode sheet (1) at the top of the positive electrode collector plate (6), that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com