Grain dryer capable of winnowing grain husks

A dryer and chaff technology, applied in dryers, drying, non-progressive dryers, etc., can solve the problems of wasting time, manpower and material resources, long drying time, waste of resources, etc., and achieve faster stirring speed. , Improve drying effect, complete heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

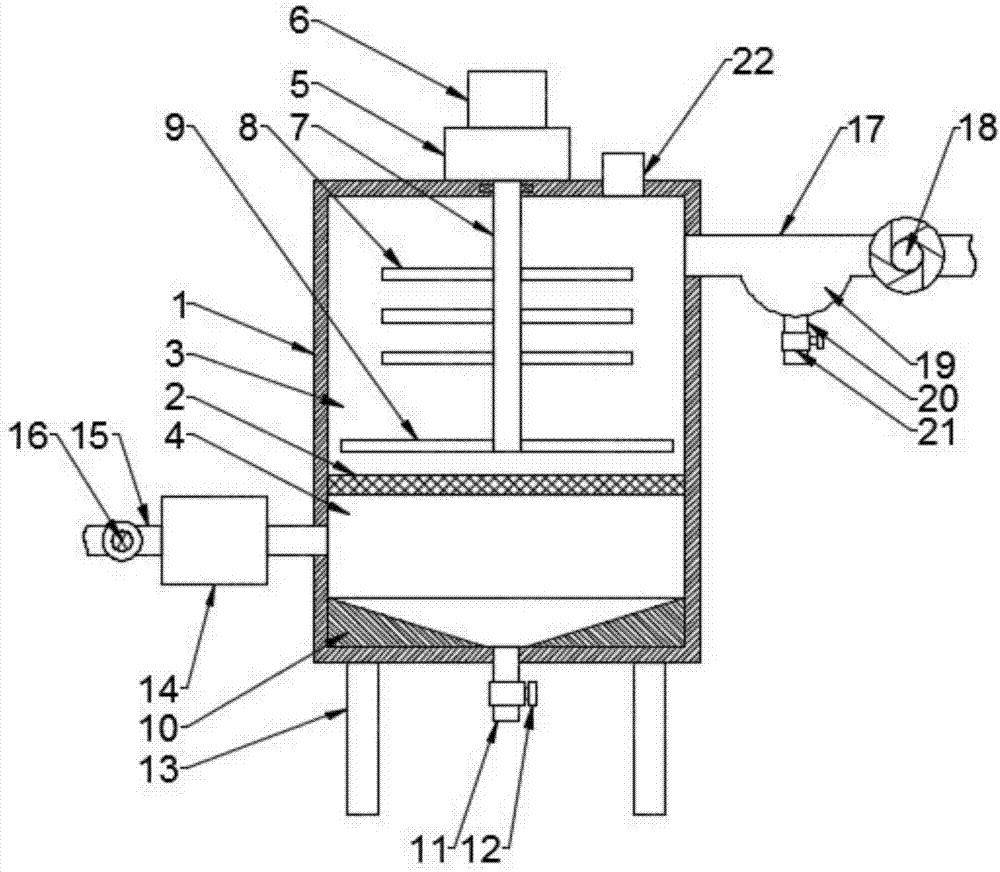

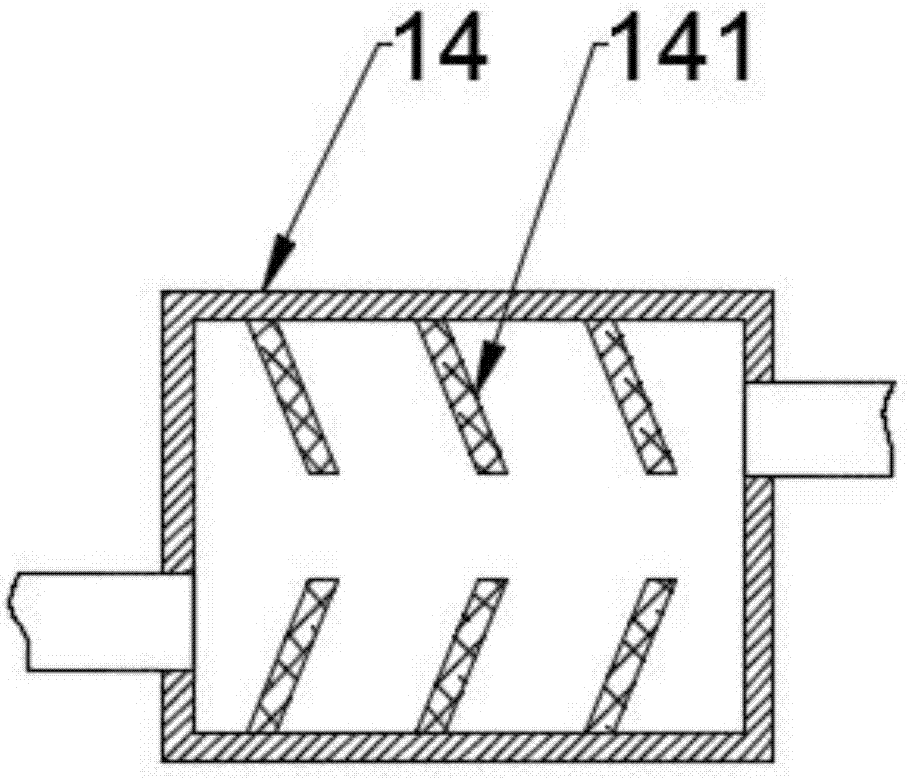

[0017] see Figure 1~2 , a grain dryer capable of gas-selecting chaff, comprising a drying box 1, the bottom of the inner cavity of the drying box 1 is provided with a screening net 2, and the screening net 2 divides the inner cavity of the drying box 1 into A drying chamber 3 and a discharge chamber 4, the drying chamber 3 is arranged above the discharge chamber 4, a stirring rod 7 is arranged in the drying chamber 3, and a number of stirring blades are uniformly arranged in the middle of the stirring rod 7 8. The bottom end of the stirring rod 7 is evenly provided with a number of scrapers 9 in the circumferential direction, the distance between the scraper 9 and the screen 2 is 1 cm to 2 cm, and the top of the stirring rod 7 passes through the drying box The top wall of 1 is connected to the speed reducer 5 in rotation, and the stirring rod 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com