Full-mechanized coal mining coal-pillar-free sublevel filling coal mining method for steeply inclined coal seam strike

A filling coal mining and steep inclination technology, which is applied to filling materials, ground mining, mining equipment, etc., can solve the problems of low resource recovery rate and high cost of filling and transportation, and achieve the goal of improving resource recovery rate, controlling surface subsidence, and reducing pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

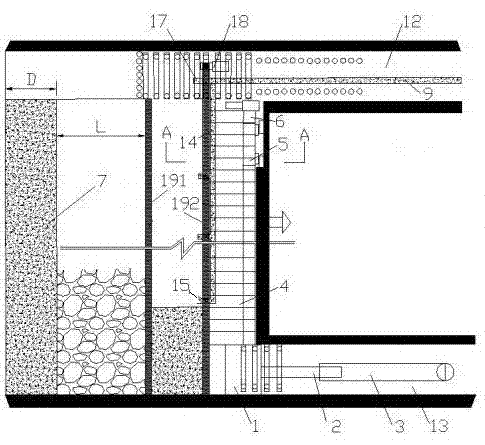

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0039] Such as figure 1 As shown, a kind of fully mechanized coal mining method with no coal pillar and subsection filling in the trend of steeply inclined coal seam includes the following steps:

[0040] S1: During the recovery process of the steeply inclined working face, after advancing a filling span L, a first filling formwork 191 is installed between the upper trough 12 and the lower trough 13, and the first filling formwork 191 is next to the mining goaf;

[0041] S2: After the mining face continues to advance a filling column distance D, a second filling formwork 192 is installed between the upper trough 12 and the lower trough 13, and the second filling formwork 192 is next to the mining goaf;

[0042] S3: Fill the paste between the first filling template 191 and the second filling template 192, and fill the paste between the first filling template (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com