Down-hole water drainage and gas production tool

A technology of drainage gas recovery and tools, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., and can solve the problem of not being able to use high-inclination wells and horizontal wells for drainage and gas recovery operations, and the investment in mechanical pumping drainage and gas recovery processes Cost and maintenance costs cannot meet the development needs of low-yield gas wells, etc., to achieve the effect of simple construction operations and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

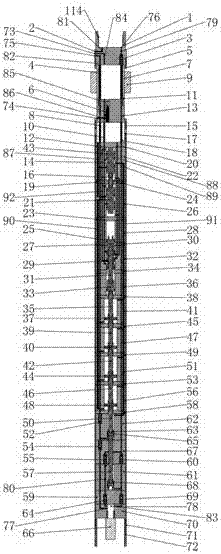

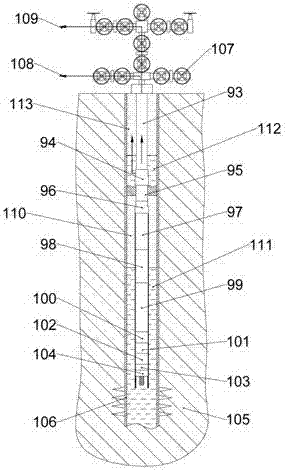

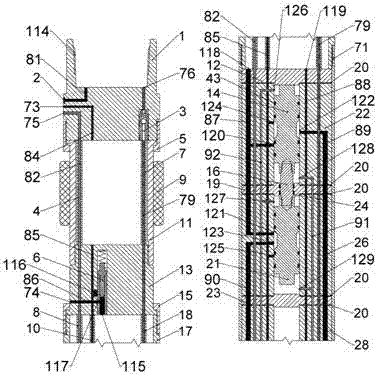

[0022] The present invention will be further described below in conjunction with the accompanying drawings: a downhole drainage and gas production tool, mainly comprising: a transition joint 94, a packer module 95, an overflow valve module 96, a reversing valve module 97, a pilot valve module 98, and a drive module 99. The No. 2 pump module 100, the check valve nipple A101, the No. 1 pump module 102, the check valve nipple B103, the bottom end 104, 71 the main outer cylinder and 72 the pressure cap. The downhole drainage and gas production tool is connected with the oil pipe 93 through the transition joint 94 and lowered into the well, the packer 11 is set, and the drainage and gas production operation can be carried out after the wellhead device 107 and the surface production pipeline are installed; the function of the packer 11 is to The wellbore is divided into two parts: the upper annular space of the packer rubber barrel 9 is composed of the packer upper annular liquid 112...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com