Wall brushing method before cleaning groove hole of concrete diaphragm wall with mucky sand inclusion layer and device thereof

A ground-connected wall and silt-based technology, which is applied to sheet pile walls, buildings, and infrastructure projects, can solve the problems of equipment scheduling and arrangement that cannot be cleaned in time, poor joints of ground-connected walls, and increased project costs, etc., to achieve The effect of saving equipment rental and operating costs, saving time, and saving calling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

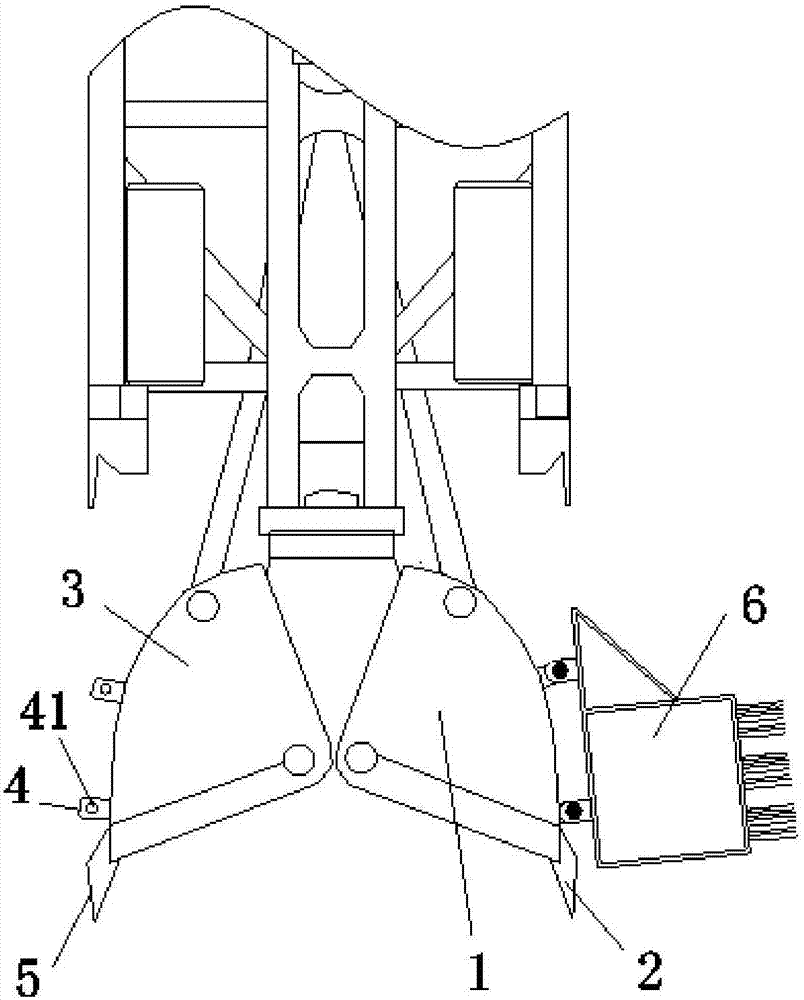

[0044] Such as Figure 9 Shown is the flow chart of the wall brushing method before the cleaning of the silty sand-included formation ground connection wall slot hole hole clearing provided by the present invention. As can be seen from the figure, the wall brushing method of the present invention includes the following steps:

[0045] The grooving machine performs grooving construction on the silty sand-containing stratum through the grab bucket on which the first bucket tooth is installed, forming the first-stage groove hole 11 of the ground connection wall;

[0046] After the first-stage slot hole 11 is formed, set the I-beam into the first-stage slot hole along with the reinforcement cage, so as to form the I-beam joint 10, and one side of the I-beam joint 10 faces the first-stage slot;

[0047] Fill the filler 8 on the other side of the I-beam joint 10, and pour concrete into the slot hole of the first-stage groove to form the first-stage groove section of the ground conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com