Anti-unbalance-load and anti-winding device for pulsator washing machine with different water leaf and barrel diameter

A pulsator washing machine and anti-entanglement technology, which can be applied to other washing machines, applications, washing devices, etc., can solve the loss of cleaning power, and can not solve the problems of eccentric load of the pulsator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

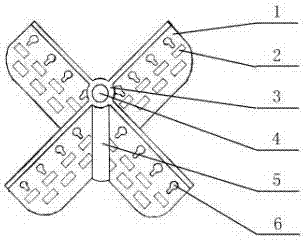

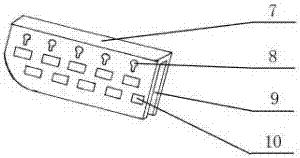

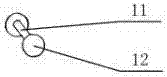

[0040] An anti-eccentric load and anti-winding device for pulsator washing machines with different water blades and bucket diameters, comprising a hollow partition fixing column 5, the bottom of which is closed, and four holes are arranged on the hollow partition fixing column along the circumferential direction. A space divider 1, the space divider evenly divides the space of the washing tub, so that the multiple pieces of laundry in the washing tub can be evenly distributed in each separated space, reducing the winding during the washing process and the deviation during the dehydration process. The lower edge of the space divider is in the shape of an arc matching the outer arc of the bottom of the washing bucket, and the water guide hole 2 is set on the space divider, and the water guide hole is a rectangular hole distributed on the space divider, so that the washing liquid It can flow in the separate spaces of the washing tub; a handle 3 is provided on the upper end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com