Film forming device, film forming method and film forming source

A film-forming device and film-forming source technology, which is applied to the metal material coating process, vacuum evaporation plating, coating, etc., can solve the problem of uneven film formation, waste of plating materials, and uncontrollable rate of film formation of sublimation materials And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with examples, which are only preferred implementations of the present invention, and are not limitations of the present invention.

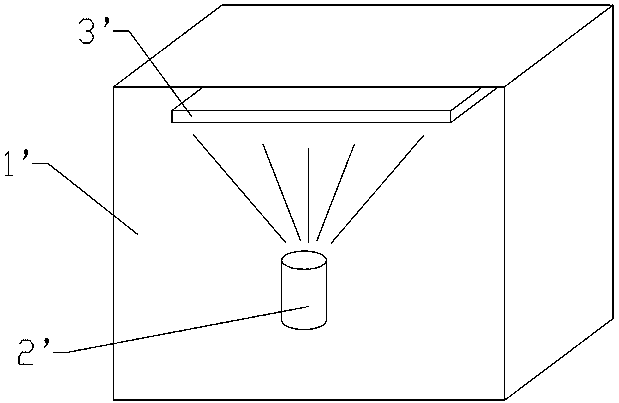

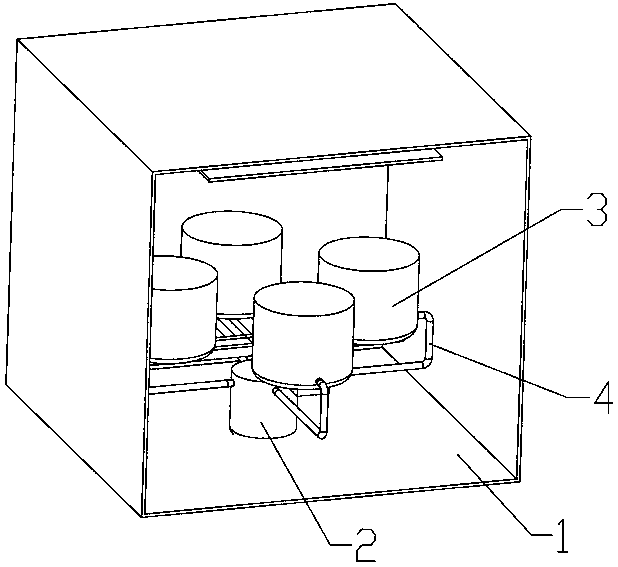

[0037] figure 2 It is an explanatory diagram showing a basic configuration of a film forming source or a film forming apparatus using the film forming source according to an embodiment of the present invention. A film-forming device, which has a film-forming chamber 1, a film-forming source, and a controller. In the film-forming chamber 1 in a vacuum or decompressed state, the sublimated or evaporated film-forming material is formed into a film on a substrate to be formed. membrane surface.

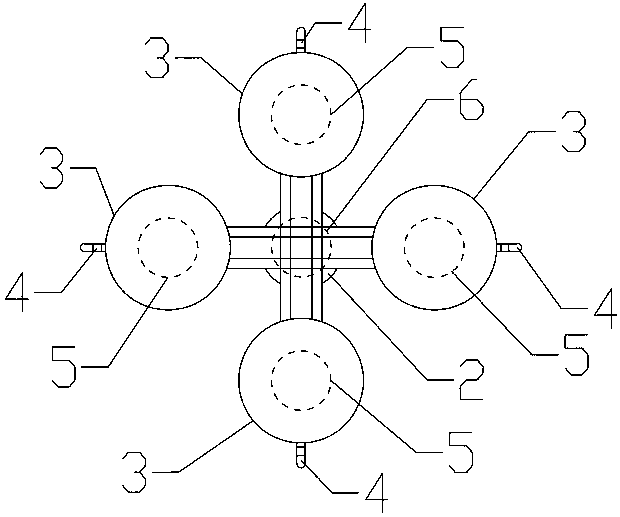

[0038] Such as figure 2 , 3 As shown, the film-forming source includes a heating crucible 2 that heats the film-forming material to vaporize or sublime into a gaseous state, and at least two buffers 3 that are airtightly communicated with the heating crucible 2 and are used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com