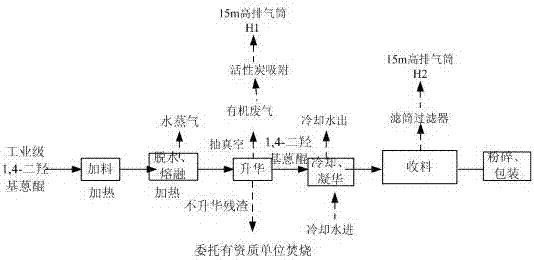

High-vacuum sublimation purification method of 1,4-dihydroxyanthraquinone

A dihydroxyanthraquinone and high-vacuum technology, which is applied in the purification of pharmaceutical intermediates and the field of dyes, can solve the problems of increased thermal decomposition loss, high cost, and low vacuum degree, so as to increase the sublimation speed, shorten the production cycle, and increase the vacuum ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1 (New Law 1)

[0058] The method for purifying 1,4-dihydroxyanthraquinone by high vacuum sublimation is prepared according to the following steps and process conditions:

[0059] Step 1), charging and feeding: Pour the industrial-grade 1.4-dihydroxyanthraquinone (content about 94%, moisture ≤ 1%) synthesized from hydroquinone and phthalic anhydride on the charging platform, and use a special The stainless steel trough is loaded, compacted, scraped, and placed on the feeding cart; the trough is put into the sublimation tube of each honeycomb sublimator, and the trough is required to be aligned and pushed into the sublimation tube; 12 parallel The sublimation tubes of the honeycomb sublimator are all filled, and a total of 400kg is fed.

[0060] Step 2), dehydration and melting: the heat source is supplied by a gas-fired heat-conducting oil furnace, and the temperature is controlled at 210-220°C. After a small amount of water is discharged, the material begins t...

Embodiment 2

[0068] Example 2 (new method 2)

[0069] The sublimation equipment is the same as in Example 1; it is prepared according to the following steps and process conditions:

[0070] Step 1), charging and feeding: Pour the industrial-grade (content about 92%, moisture ≤ 1%) 1.4-dihydroxyanthraquinone material synthesized from p-chlorophenol and phthalic anhydride on the charging platform, and use a special stainless steel Fill the trough, compact it, scrape it flat, and place it on the feeding cart; put the trough into the sublimation tube of each honeycomb sublimator. The sublimation tubes of the 12 honeycomb sublimators are all filled, and a total of 250kg is fed.

[0071] Step 2), dehydration, melting: the heat source is supplied by a gas-fired heat-conducting oil furnace, and the temperature is controlled at 240-245°C. After a small amount of water in the raw material is discharged, the material begins to melt. After the material is completely melted, close the cover and tighte...

Embodiment 3

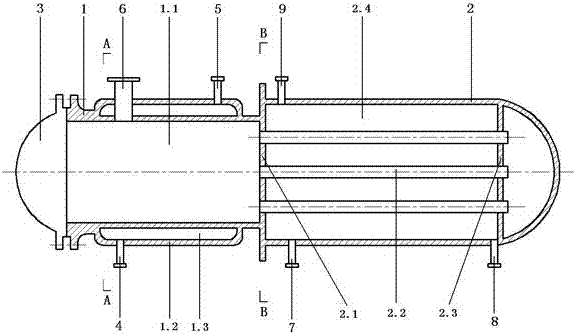

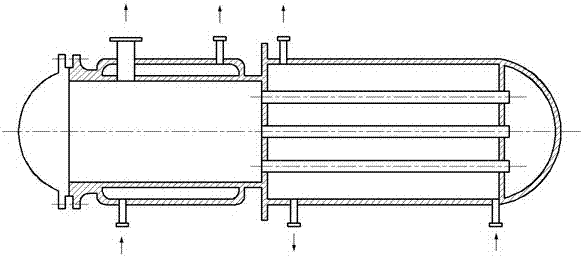

[0086] The method for purifying 1, 4-dihydroxyanthraquinone by high vacuum sublimation, and the used honeycomb sublimator;

[0087] Such as figure 2 , image 3 , Figure 4 with Figure 5 As shown, the honeycomb sublimator includes a crystallization tank body 1, a heating tank body 2, a tank cover 3, a tube plate 2.1, a sublimation tube 2.2, a support plate 2.3 and a trough; in the crystallization tank body 1 A crystallization chamber 1.1 is provided; a heating chamber 2.4 is provided in the heating tank body 2; one end of the crystallization tank body 1 is connected to the non-closed end of the heating tank body 2 through a tube plate 2.1; the crystallization tank body 1 is separately One end is hinged with the tank cover 3; the tube plate 2.1 is provided with a honeycomb through hole; the heating chamber 2.4 is provided with a support plate 2.3; the support plate 2.3 is provided with a honeycomb through hole with the tube plate 2.1 Corresponding through holes; the sublimat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com