Turnover device for car part detection

A technology for turning over devices and auto parts, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of waste of resources, missing defective products, destroying production lines, etc., to achieve convenient handling, improve strength, improve flexibility and work. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

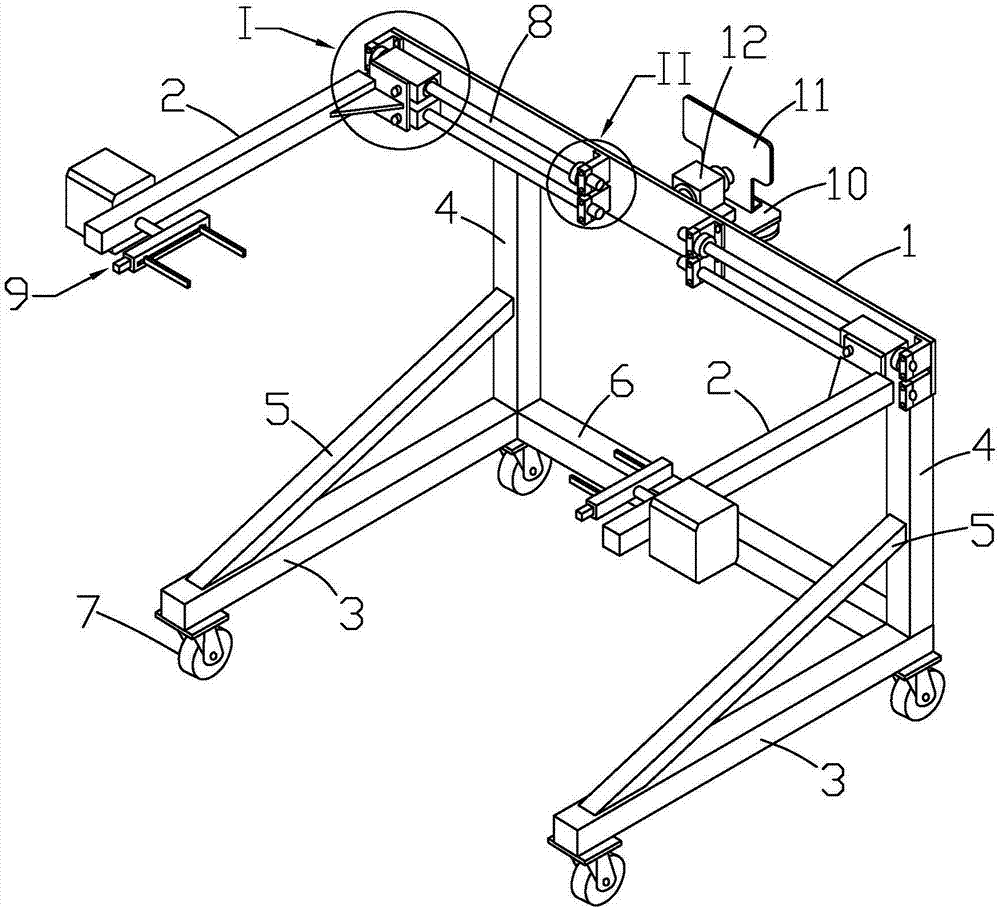

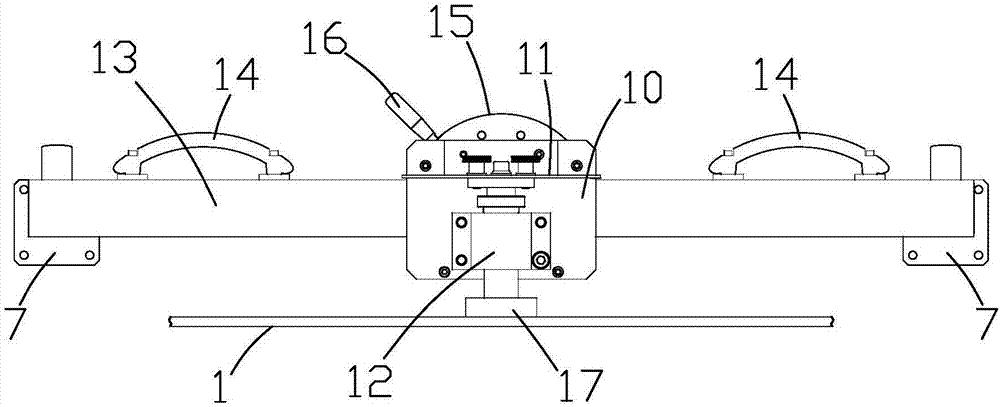

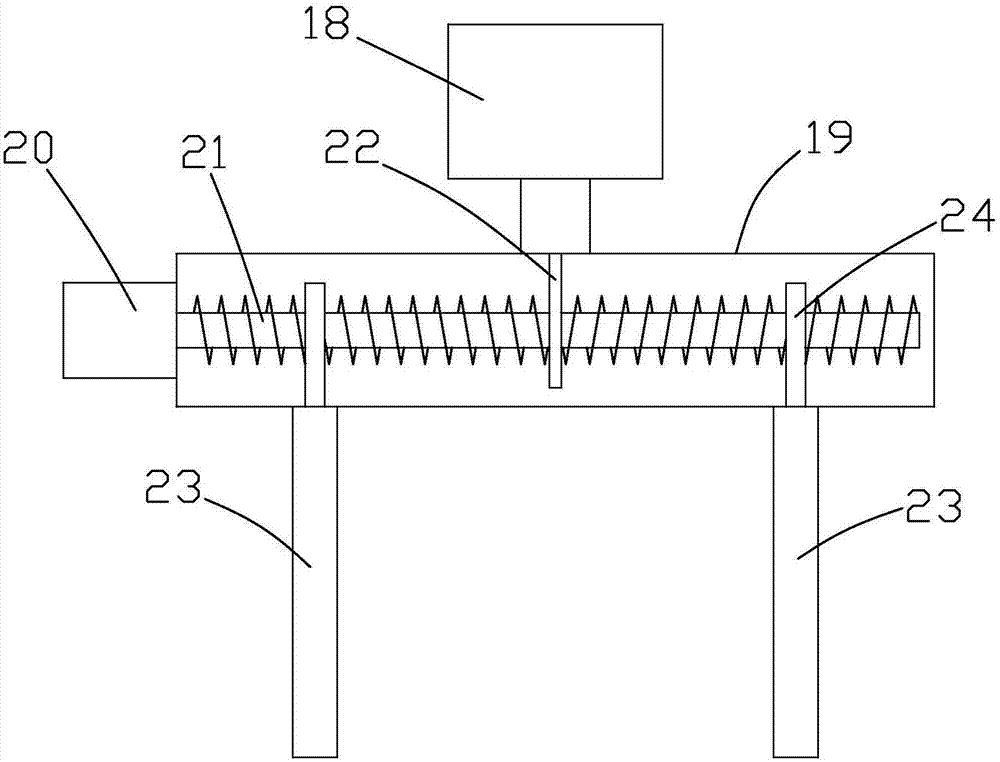

[0030] Such as Figure 1 to Figure 5 Shown here is a turning device for detecting auto parts of the present invention. It includes a rotating plate 1, a supporting mechanism and a rotating mechanism. The supporting mechanism includes an upper fixed rod 13, a lower fixed rod 6, a support rod 4 and a positioning rod 3. The fixing rod 13 and the lower fixing rod 6 are arranged in parallel up and down, the two positioning rods 3 are arranged in parallel, the ends of the two positioning rods 3 are connected by the lower fixing rod 6, the support rod 4 is vertically connected to the positioning rod 3, and the support rod 4 and A reinforcing rod 5 is arranged between the positioning rods 3, and the upper fixing rod 13 is fixedly connected to the top ends of the two supporting rods 4. The two positioning rods 3 and the lower fixing rod 6 form a U-shaped structure, which improves the stability of the supporting rod 4. The reinforcing rod 5 effectively improves the strength of the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com