Embedding jig of module power supply and embedding device with embedding jig

A module power supply and fixture technology, which is applied in the field of potting and sealing technology, can solve the problems that the glue cannot flow, the bubbles of the module power supply cannot be eliminated, and the life of the module power supply is shortened, so as to achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

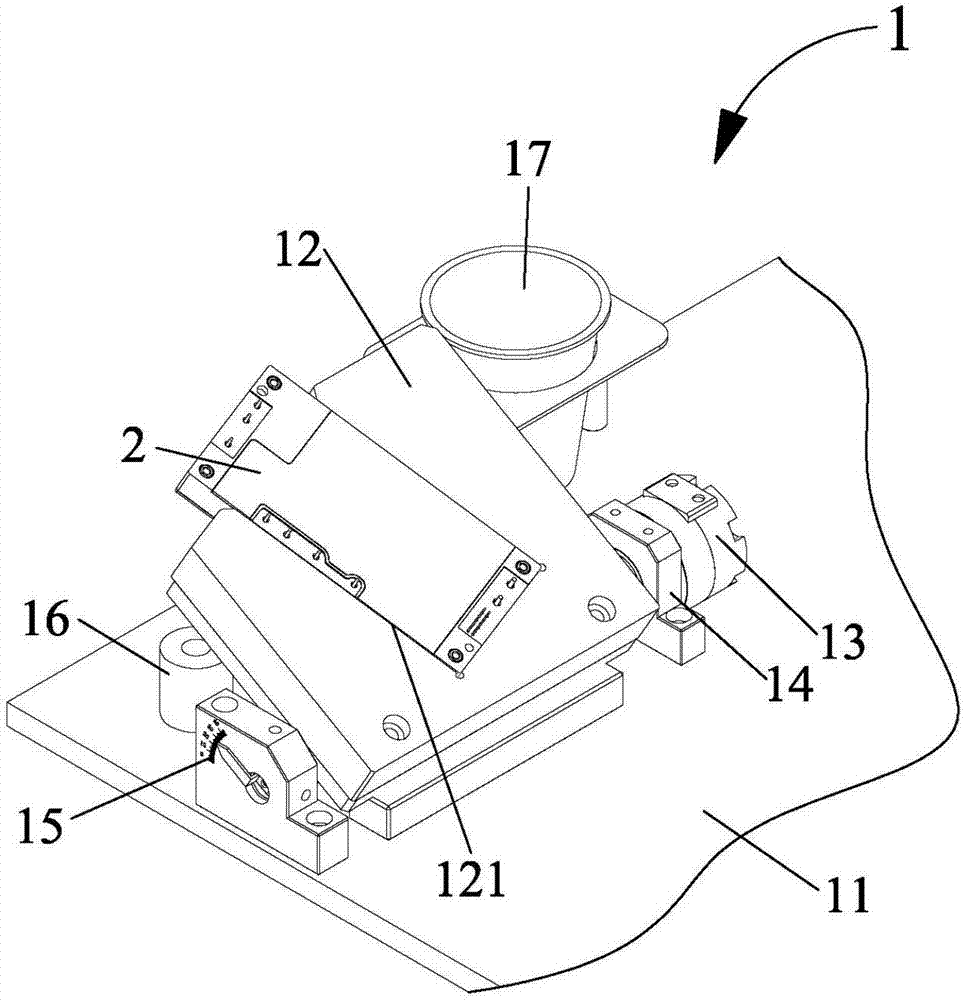

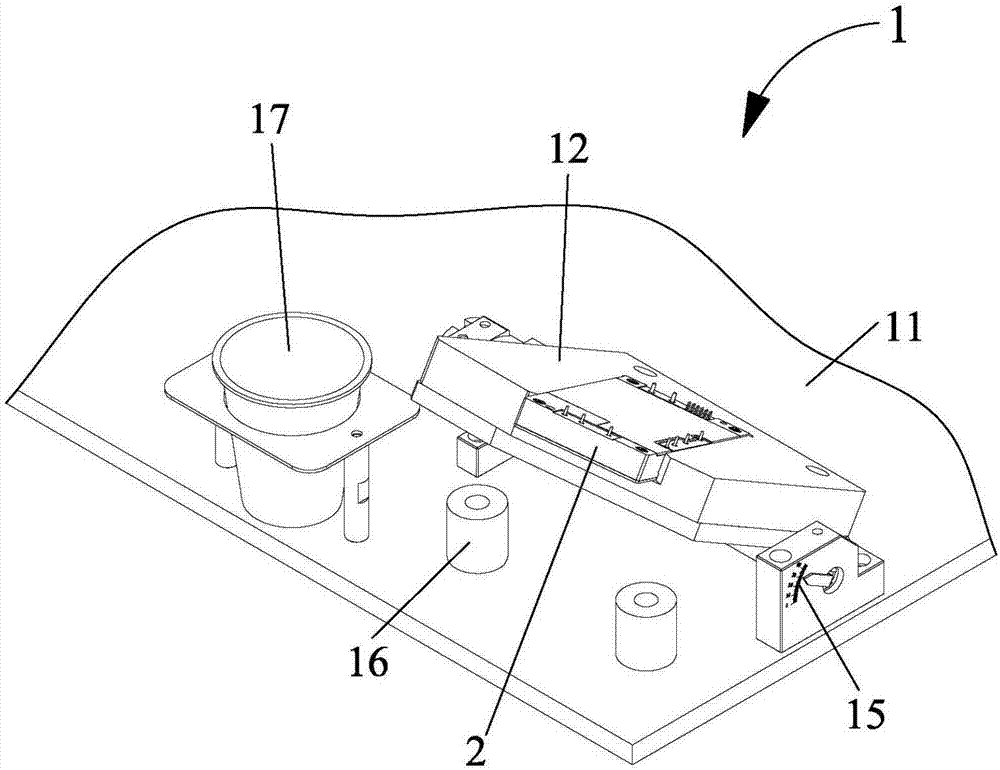

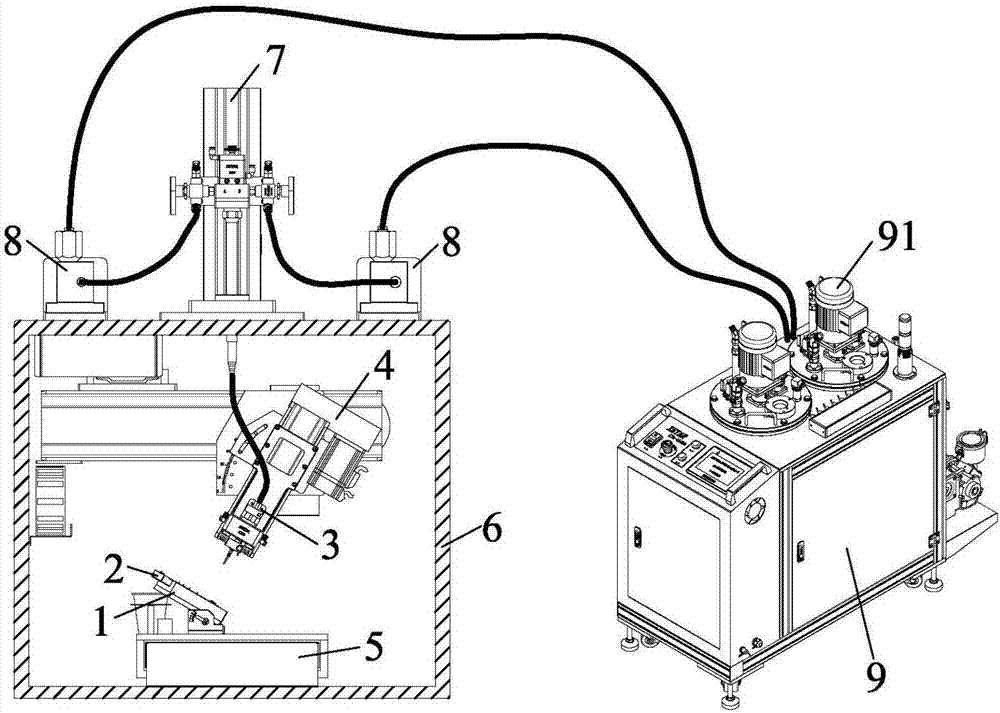

[0023] like figure 1 and figure 2 As shown, it is a schematic structural diagram of the potting fixture 1 of the preferred embodiment of the present invention. The potting fixture 1 includes a fixture base 11, a fixture main body 12, a cylinder 13, a base 14, an angle indicator 15, and a cushion 16 and a waste cup 17, wherein the jig main body 12 is used to fix the module power supply 2 to be potted, and the jig main body 12 is rotatably connected to the jig base 11 to drive the power supply 2 of the to-be-potted module to rotate; the jig main body 12 is provided with a concave Groove 121, the groove 121 is matched with the power supply 2 of the module to be potted, so that the power supply 2 of the module to be potted can be quickly positioned and fixed on the jig body 12, and ensure that no deviation occurs during the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com