Automatic load regulating device and method used for tube bundle type dust-removing mist eliminator

A load adjustment and mist eliminator technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of decreased dust removal and mist removal performance, low gas flow rate, and difficulty in removing fine dust and gypsum droplets, etc. To ensure the effect of dust removal and fog removal, the gas flow rate is stable, and the effect of solving difficult removal is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

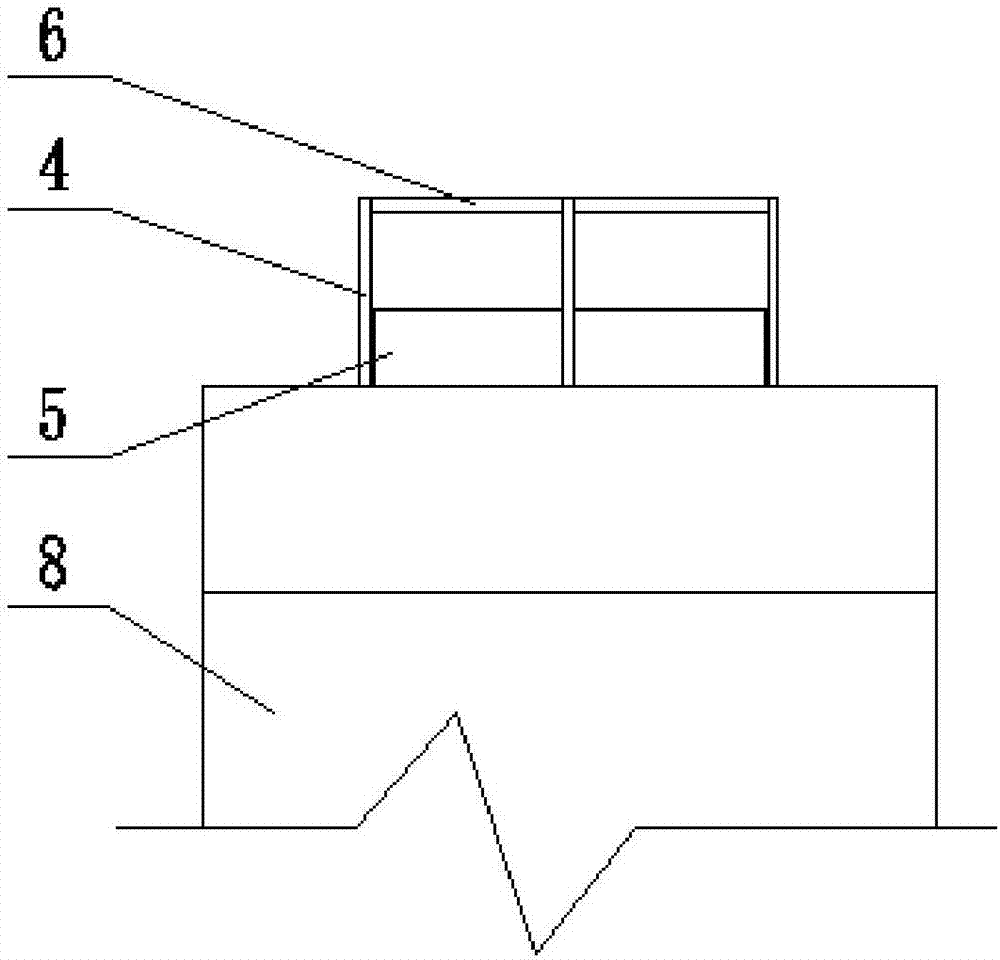

[0023] Such as Figure 1 to Figure 4 As shown, the automatic load adjustment device for the tube bundle dust and mist eliminator according to the present invention includes a liquid blocking ring 1, a guide ring 2, a float support ring 3, fins 4, floats 5 and a top plate 6;

[0024] The liquid retaining ring 1 is installed on the outlet above the cylinder of the tube bundle type dedusting and mist eliminator 8, and the top of the liquid retaining ring 1 is sequentially installed with a guide ring 2 and a float support ring 3, and the inner wall of the float support ring 3 is provided with Wedge-shaped gap, a plurality of ribs 4 are distributed in the wedge-shaped gap of the float support ring 3, the float 5 is slidably connected with the ribs 4, the outer wall of the float 5 is provided with a chute that matches the rib 4, the lower end of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com