Method for regulating digestion performance of highland barley starch on basis of 3D printing technology

A 3D printing and highland barley technology, which is applied in food forming, food coating, and food ingredient functions, can solve problems affecting the blood sugar regulation function of highland barley powder, and achieve personalized food customization, good three-dimensional shape, and slow Effect of Digestive and Resistant Starch Increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

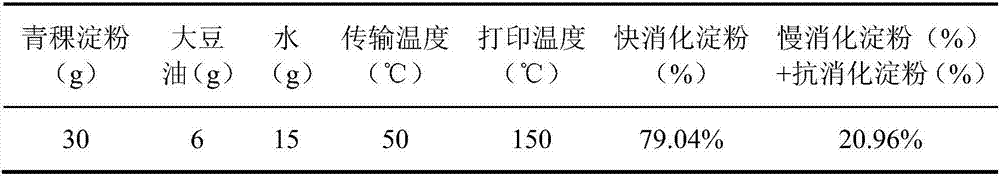

Embodiment 1

[0021] Select highland barley starch and soybean oil as raw materials, according to the ratio of highland barley starch: water: oil of 1:0.5:0.2, first add water to the highland barley starch for preliminary mixing, then add oil and stir well with a mixer. Then the starch-oil composite system after stirring is added into the material cylinder of the 3D printer. After setting the transmission temperature and keeping it for 30 minutes, 3D printing was performed at the printing temperature.

[0022] The in vitro digestibility of the highland barley starch and oil compound obtained by 3D printing was tested, and the contents of fast-digesting components, slow-digesting components and anti-digesting components are shown in Table 1.

[0023] Table 1

[0024]

Embodiment 2

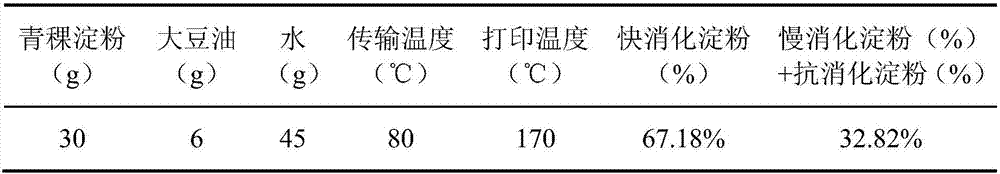

[0026] Select highland barley starch and soybean oil as raw materials, according to the ratio of highland barley starch: water: oil 1:1:0.2, first add water to the highland barley starch for preliminary mixing, then add oil and stir well with a mixer. Then the starch-oil composite system after stirring is added into the material cylinder of the 3D printer. After setting the transmission temperature and keeping it for 25 minutes, 3D printing was performed at the printing temperature.

[0027] The highland barley starch and oil compound obtained by 3D printing was tested for in vitro digestibility, and the contents of fast-digesting components, slow-digesting components and anti-digesting components are shown in Table 2.

[0028] Table 2

[0029]

Embodiment 3

[0031] Select highland barley starch and soybean oil as raw materials, according to the ratio of highland barley starch: water: oil of 1:1.5:0.2, first add water to the highland barley starch for preliminary mixing, then add oil and stir well with a mixer. Then the starch-oil composite system after stirring is added into the material cylinder of the 3D printer. After setting the transmission temperature and keeping it for 10 minutes, 3D printing was performed at the printing temperature.

[0032] The highland barley starch and oil compound obtained by 3D printing was tested for in vitro digestibility, and the contents of fast-digesting components, slow-digesting components and anti-digesting components are shown in Table 3.

[0033] table 3

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com