Method for preparing black brin extract for cigarette by immobilized saccharomycetes

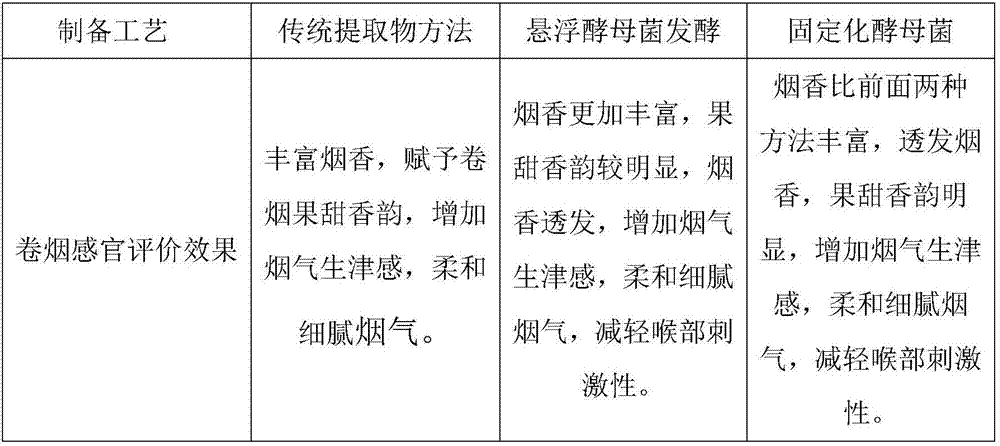

A technology of yeast and extract, which is applied in the field of preparing black pulin extract for tobacco, to achieve the effects of reducing irritation, increasing fruity sweet aroma, and soft and delicate smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Take fresh black pudding, remove the core, squeeze the juice, sterilize at 121°C for 20 minutes, cool, and filter to obtain black pudding juice;

[0021] (2) Saccharomyces bacterium suspension preparation: inoculate saccharomycete in broth culture medium, the specific formula of broth culture medium is (per liter): peptone 10g, beef extract powder 3g, sodium chloride 5g, final pH7. 3±0.1, cultured for 48 hours at a temperature of 37°C and a stirring speed of 50 rpm, took the culture solution and centrifuged at 8000 rpm, and the wet cells after centrifugation were used for later use;

[0022] (3) Sodium alginate-CaCl of yeast 2 Immobilization: Prepare a sodium alginate solution with a mass fraction of 4%, and then add 3% of its volume of the yeast wet cell prepared in the step (2) to prepare a mixed solution, and use a peristaltic pump to pass through a 1mm aperture Add the prepared mixture dropwise to the CaCl with a mass fraction of 3% 2 solution, into balls, and...

Embodiment 2

[0026] (1) Take fresh black pudding, remove the core, squeeze the juice, sterilize at 121°C for 20 minutes, cool, and filter to obtain black pudding juice;

[0027] (2) Saccharomyces bacterium suspension preparation: inoculate saccharomycete in broth culture medium, the specific formula of broth culture medium is (per liter): peptone 10g, beef extract powder 3g, sodium chloride 5g, final pH7. 3±0.1, cultured for 48 hours at a temperature of 37°C and a stirring speed of 50 rpm, took the culture solution and centrifuged at 8000 rpm, and the wet cells after centrifugation were used for later use;

[0028] (3) Sodium alginate-CaCl of yeast 2 Immobilization: Prepare a sodium alginate solution with a mass fraction of 5%, then add 4% of its volume of the yeast wet cell prepared in the step (2), prepare a mixed solution, and use a peristaltic pump to pass through a 3mm aperture Add the prepared mixture dropwise to the CaCl with a mass fraction of 4% 2 solution, into balls, and the C...

Embodiment 3

[0032] (1) Take fresh black pudding, remove the core, squeeze the juice, sterilize at 121°C for 20 minutes, cool, and filter to obtain black pudding juice;

[0033] (2) Saccharomyces bacterium suspension preparation: inoculate saccharomycete in broth culture medium, the specific formula of broth culture medium is (per liter): peptone 10g, beef extract powder 3g, sodium chloride 5g, final pH7. 3±0.1, cultured for 48 hours at a temperature of 37°C and a stirring speed of 50 rpm, took the culture solution and centrifuged at 8000 rpm, and the wet cells after centrifugation were used for later use;

[0034] (3) Sodium alginate-CaCl of yeast 2 Immobilization: Prepare a sodium alginate solution with a mass fraction of 5%, then add 5% of its volume of the yeast wet cell prepared in the step (2), prepare a mixed solution, and use a peristaltic pump to pass through a 4mm aperture Add the prepared mixed solution drop by drop to the CaCl with a mass fraction of 6%.2 solution, into balls,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com